- Joined

- Feb 17, 2021

- Messages

- 468

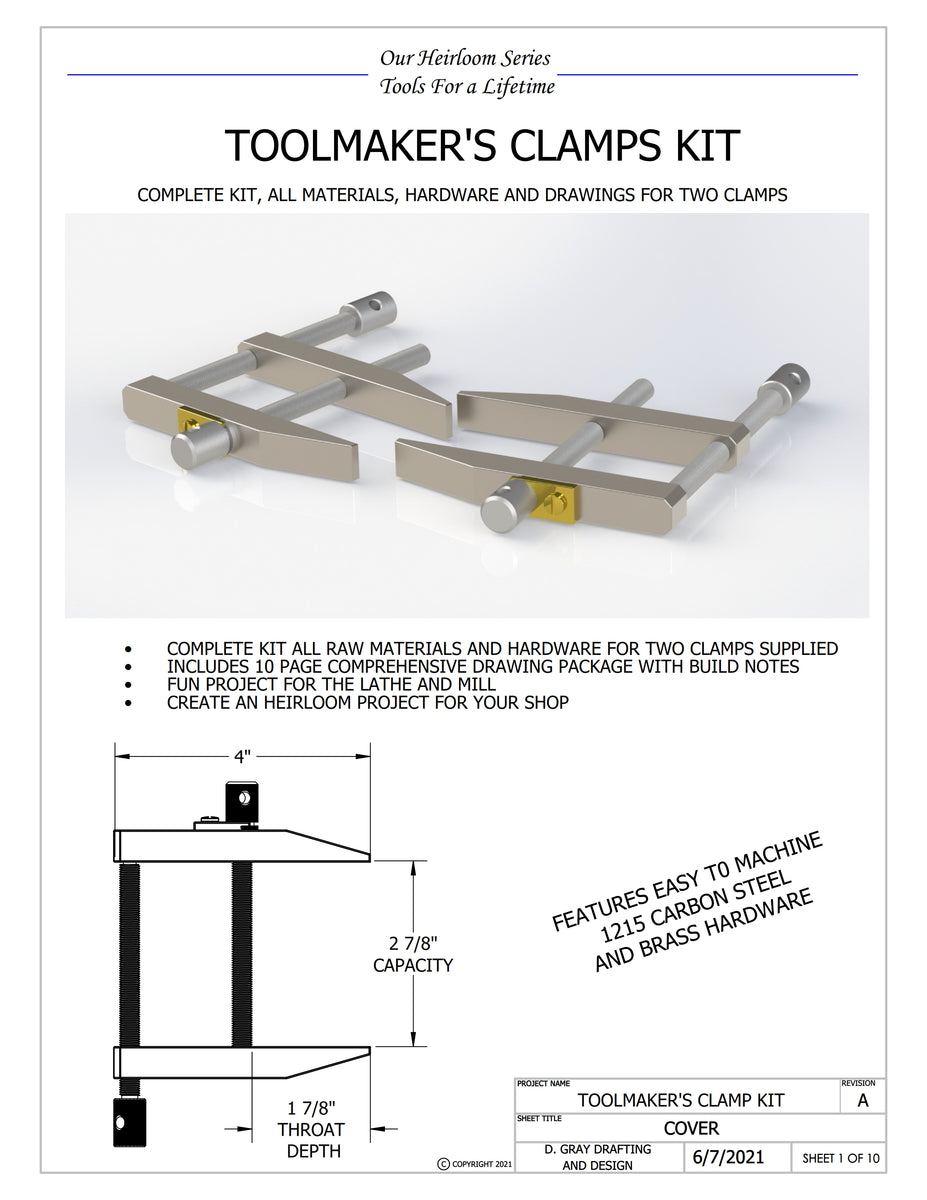

BEEN PLAYING WITH this metal hobby for around 18 months and made some pretty nice useful stuff with the lathe, ever since I got a mill have gone blank thinking up projects, prolly cuzz all Ive done is lathe work all this time..... looked on youtube several times still cant find much re lathe / mill projects however did run across a site that involved "class room ed. projects that seemed to fit my style and were useful, so copied plans and made the part. If anyone here has ran across more of those "Class Room Ed. projects go ahead and post it here..........am mostly interested with small 6061 12L14 and 1018 project exersizes........