- Joined

- Feb 27, 2014

- Messages

- 2,129

No sure if this is what your asking but part of the GCode does define the feed rate and can be and often is set for each operation. for instance

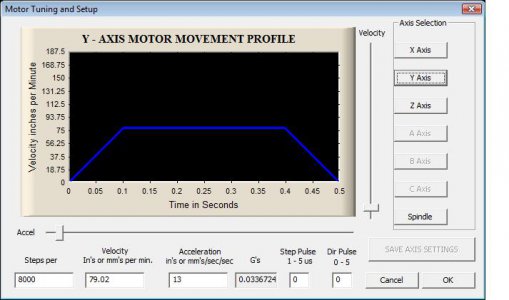

G1 x2 y3 F10 would be to move to X=2 and Y=3 (if in absolute mode) and the F10 means to move at a rate of 10 units per second or 10 inches per second in my case. There is a maximum feed rate that is set in the Mach3 configuration pages but operational feed rates should be defined in the Gcode. I don't know if Feed rates for engraving tend to be constant but for Metal Milling work the feed rates change based on the Type of Material, Type of Cutter, Size of Cutter, Depth of Cut etc. In fact there is a whole science if determining the correct FEEDs and SPEEDS for a given cut and many calculators to make the calculations for you or easier.

G1 x2 y3 F10 would be to move to X=2 and Y=3 (if in absolute mode) and the F10 means to move at a rate of 10 units per second or 10 inches per second in my case. There is a maximum feed rate that is set in the Mach3 configuration pages but operational feed rates should be defined in the Gcode. I don't know if Feed rates for engraving tend to be constant but for Metal Milling work the feed rates change based on the Type of Material, Type of Cutter, Size of Cutter, Depth of Cut etc. In fact there is a whole science if determining the correct FEEDs and SPEEDS for a given cut and many calculators to make the calculations for you or easier.