- Joined

- Jan 20, 2016

- Messages

- 1,011

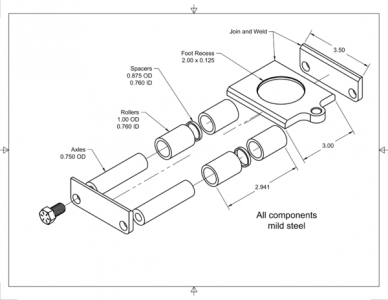

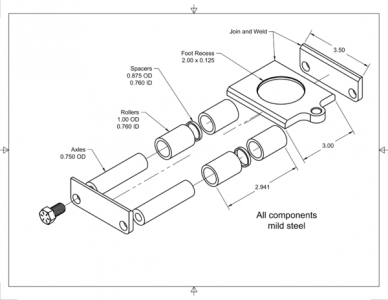

Awhile back I thought I was going to give myself a lathe DRO for Christmas. I will have to move the lathe to install the DRO (I want to move it anyway). Unfortunately I am not able to get the DRO just yet. Several things came up (dentist, bearings in mill spindle, air compressor overhaul, to name a few). But since I had already started on a prototype for a cheap machine skate I thought I would finish it. Keep in mind that I just have an Asian 12x36 lathe on a steel tube stand. My guess is that without unloading the storage shelf maximum weight will be less than 2,000 lbs.

I don't have any idea if this design will work. The rollers might collapse, flat spot or just not roll. Won't know until I try them. I figure I can always turn the axles to accept cheap bearings and go that route. I am just hoping to spare the expense of bearings using these bushing type of rollers.

When I designed the stand for the lathe I made sure that the lifting leg attachment for my port-o-power can raise the lathe to get the skates in place.

Today I will weld the frames (after a little TIG welding practice) and give them a try.

As for finish I haven't decided if I will paint, powder coat or just let them rust. Tolerances are close so powder coat is not likely.

If they work (or even if not) I have PDF and CAD drawings I would be glad to share. If they do work I think I can pack them in a small USPS box if anyone wants to borrow them.

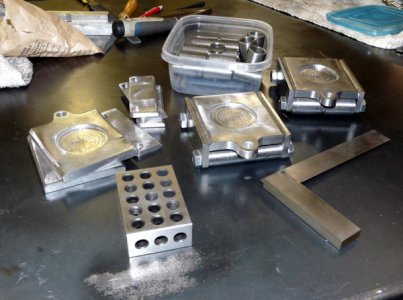

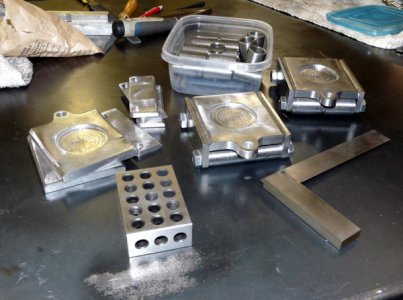

The skate on the left has just the axles installed, the skate on the right has the rollers and spacer installed. Just need to weld them up. Chamfers cut for welding.

The skate on the left has just the axles installed, the skate on the right has the rollers and spacer installed. Just need to weld them up. Chamfers cut for welding.

Bottom side.

Bottom side.

(pictures are thumbnails - click to enlarge)

I don't have any idea if this design will work. The rollers might collapse, flat spot or just not roll. Won't know until I try them. I figure I can always turn the axles to accept cheap bearings and go that route. I am just hoping to spare the expense of bearings using these bushing type of rollers.

When I designed the stand for the lathe I made sure that the lifting leg attachment for my port-o-power can raise the lathe to get the skates in place.

Today I will weld the frames (after a little TIG welding practice) and give them a try.

As for finish I haven't decided if I will paint, powder coat or just let them rust. Tolerances are close so powder coat is not likely.

If they work (or even if not) I have PDF and CAD drawings I would be glad to share. If they do work I think I can pack them in a small USPS box if anyone wants to borrow them.

The skate on the left has just the axles installed, the skate on the right has the rollers and spacer installed. Just need to weld them up. Chamfers cut for welding.

The skate on the left has just the axles installed, the skate on the right has the rollers and spacer installed. Just need to weld them up. Chamfers cut for welding. Bottom side.

Bottom side.(pictures are thumbnails - click to enlarge)

Last edited:

The 0.010" clearance sure feels like it is plenty of room to allow for oil (teflon is a good idea) or even grease. There is about 0.010" of end play for each end of each roller and spacer or a total of 0.060" for the 3 parts. I'm hoping the polished ends are good enough not to need soft bushings. After all, I only need to move the lathe about 10 feet (on a very smooth concrete floor) out and back in (after DRO installation).

The 0.010" clearance sure feels like it is plenty of room to allow for oil (teflon is a good idea) or even grease. There is about 0.010" of end play for each end of each roller and spacer or a total of 0.060" for the 3 parts. I'm hoping the polished ends are good enough not to need soft bushings. After all, I only need to move the lathe about 10 feet (on a very smooth concrete floor) out and back in (after DRO installation).