- Joined

- Mar 26, 2018

- Messages

- 8,408

I’ve been thinking about it for twenty minutes or so.

The project so far has been easy.

Have you machined one yet? How did you do it?

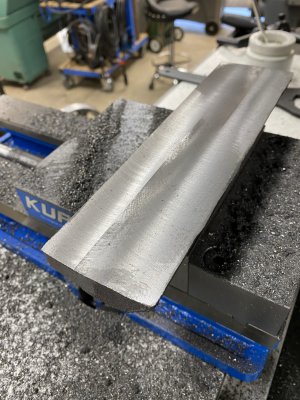

I’ll surface grind it once I figure out how to mill this. Then I’ll scrape it flat.

Thanks

The project so far has been easy.

Have you machined one yet? How did you do it?

I’ll surface grind it once I figure out how to mill this. Then I’ll scrape it flat.

Thanks

Attachments

-

A61D8833-C451-47FB-A31D-F381E35CB135.jpeg946.7 KB · Views: 56

A61D8833-C451-47FB-A31D-F381E35CB135.jpeg946.7 KB · Views: 56 -

629E17D5-995A-4630-8AF1-07232DC95359.jpeg720.3 KB · Views: 38

629E17D5-995A-4630-8AF1-07232DC95359.jpeg720.3 KB · Views: 38 -

793F11E3-D318-4E0B-AD5D-4F0F8D8CFE43.jpeg664.8 KB · Views: 32

793F11E3-D318-4E0B-AD5D-4F0F8D8CFE43.jpeg664.8 KB · Views: 32 -

3FFCCA85-A087-49D2-8A7B-819F1BE54708.jpeg921.9 KB · Views: 30

3FFCCA85-A087-49D2-8A7B-819F1BE54708.jpeg921.9 KB · Views: 30 -

CC5B214E-4EAC-46A1-9FFE-7AB1C4848B6B.jpeg1 MB · Views: 50

CC5B214E-4EAC-46A1-9FFE-7AB1C4848B6B.jpeg1 MB · Views: 50