- Joined

- Mar 26, 2018

- Messages

- 8,408

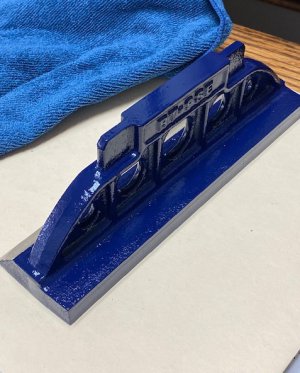

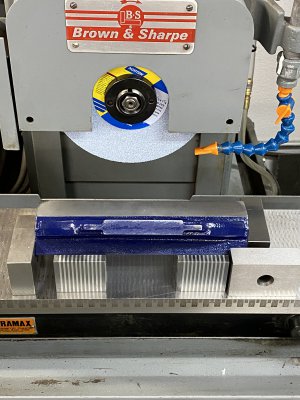

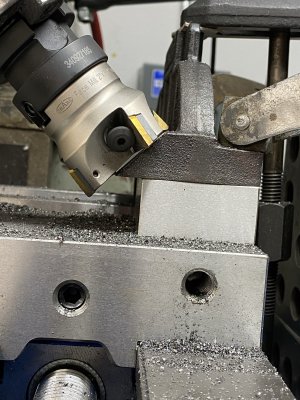

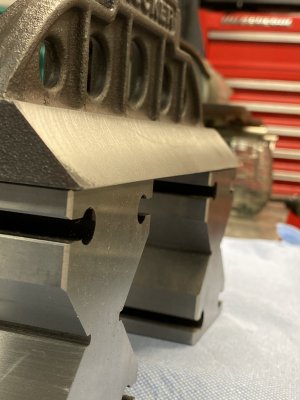

Ok, all done with the mill. On to some paint then the surface grinder.

I’m still not sure how I’m going to hold it.

I’m still not sure how I’m going to hold it.

Attachments

-

2FA76B13-BDA3-4A83-B2FF-E075643D9307.jpeg1,000.8 KB · Views: 31

2FA76B13-BDA3-4A83-B2FF-E075643D9307.jpeg1,000.8 KB · Views: 31 -

D9C2A342-9DCC-44FE-9285-9317FB5F7213.jpeg1 MB · Views: 29

D9C2A342-9DCC-44FE-9285-9317FB5F7213.jpeg1 MB · Views: 29 -

C20001C2-E2F6-44EF-A051-6B66BFA7ED05.jpeg761.7 KB · Views: 20

C20001C2-E2F6-44EF-A051-6B66BFA7ED05.jpeg761.7 KB · Views: 20 -

8307C29D-5795-47D2-8ABF-9356702C05A6.jpeg606.8 KB · Views: 19

8307C29D-5795-47D2-8ABF-9356702C05A6.jpeg606.8 KB · Views: 19 -

CE777A3E-1D14-49A9-B9DF-F259BD5FFE0B.jpeg756.8 KB · Views: 20

CE777A3E-1D14-49A9-B9DF-F259BD5FFE0B.jpeg756.8 KB · Views: 20 -

4A796442-5F30-45F3-8026-07881D3D2DEB.jpeg834.3 KB · Views: 22

4A796442-5F30-45F3-8026-07881D3D2DEB.jpeg834.3 KB · Views: 22