- Joined

- Feb 1, 2015

- Messages

- 9,610

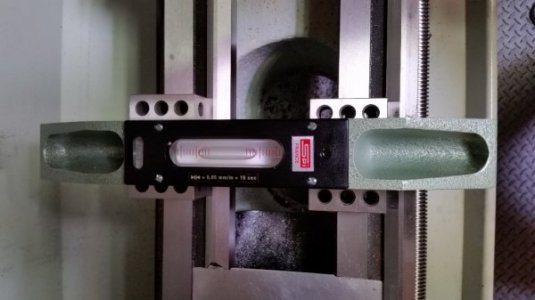

I have the iGaging digital level. Although it reads to .05º, it is reliable to .2º, or .1º at best. A .005"/10" machinists level can easily resolve a change in angle of .03º and a .0005"/10" machinists level can resolve change in angle of .003º.I have always wondered about using one of the digital angle blocks for a level. I thick sheet of paper will change the reading on mine by about .2

I don't have any idea how accurate they would be compared to a machinist level, has anyone else used them to level their lathe?

While I have not peeked inside, the iGaging level most likely makes use of a pendulum to detect a plumb condition. As such, it has a set of bearings and bearings have friction. This is the reason why you get different readings when approaching an angle from different directions or when measuring the same angle multiple times.

I use my iGaging level for doing setups where the angle is not critical. I would not attempt to use it for leveling a machine. My carpenter's level is just as sensitive and there is no bearing friction to contend with.