When I sold my Atlas 10F24, I held on to my Bison 5” 3J, as it was fairly new. Naturally I needed to make a new backing plate to mount it onto the new lathe. The old plate was 1 1/2” X 8 while the new spindle is 2 1/4” X 8, so I needed new metal to do this. I recently purchased 2 backing plates from Busy Bee Tools. They are 8” semi raw castings. They are turned to clean off the rough cast surface and the center hole is 1” ID unthreaded.

First I started by reading up on what could be the rights and wrongs in making these backing plates. Recent posting here by various people, too many to list, have been of excellent help.

I make a copy of my spindle, so that I had a plug to try the threads as they neared finish size. I used the 3 wire method to make the plug match the spindle. Once the readings were the same between the two, I was finished. I did stamp the diameter and tpi for future reference.

I am making two backing plates. One for the above Bison chuck and the second for a 5C collet chuck. It was a local purchased, used but still excellent condition. CDCO supplied said the seller.

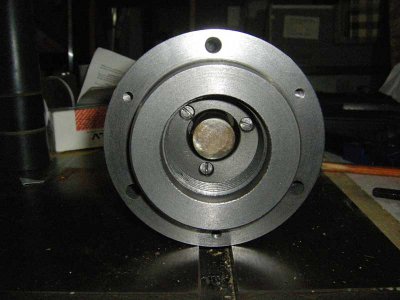

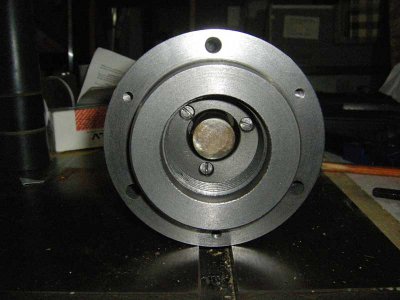

The first back plate, I chucked in my 4J, centered it and bored the spindle hole, threaded with the tool cutting on the back instead of the front side. This is so I could see what was going on. With a 2” hole this is easy to do. Faced the registration surface where the plate butts against the spindle shoulder, cut the plate back face and the shoulder OD to remove any run out. Mounted the new plate onto the spindle, cut the shoulder that fits into the back of the Bison chuck.

At this point I still had a 8” diameter plate. I needed to turn it down to slightly under 5”. I used a tool from work that is used to cut face o-ring grooves and can be used to part off the un-needed disk of material from a disk, as my plate had. Once this was done, I finished the OD and now needed to drill the mounting holes.

I did some measuring to find the center of the holes in the original plate from the Atlas and made a life size printout of the 6 holes arrayed around the shoulder that the chuck will mount to. With some careful cutting I fitted the paper to the new plate and transferred the hole positions and drill 3 holes for 1/4” X 20 thread and the alternating holes for unthreaded holes for the mounting bolts.

On the second plate I changed my method a bit. I mounted the plate first to my 4J chuck using the shoulder area and removed the outer disk first. Then I mounted it onto my 6” 3J and then cut the threads faced the registration surface and cleaned up the shoulder and back face. Next I have to check the collet chuck to see if it has any run out and then proceed with making the shoulder and mounting holes to match it. I think I will use the method mentioned on the write up at the cnccookbook.com website. I will let you know how that goes in the future.

Pierre

First I started by reading up on what could be the rights and wrongs in making these backing plates. Recent posting here by various people, too many to list, have been of excellent help.

I make a copy of my spindle, so that I had a plug to try the threads as they neared finish size. I used the 3 wire method to make the plug match the spindle. Once the readings were the same between the two, I was finished. I did stamp the diameter and tpi for future reference.

I am making two backing plates. One for the above Bison chuck and the second for a 5C collet chuck. It was a local purchased, used but still excellent condition. CDCO supplied said the seller.

The first back plate, I chucked in my 4J, centered it and bored the spindle hole, threaded with the tool cutting on the back instead of the front side. This is so I could see what was going on. With a 2” hole this is easy to do. Faced the registration surface where the plate butts against the spindle shoulder, cut the plate back face and the shoulder OD to remove any run out. Mounted the new plate onto the spindle, cut the shoulder that fits into the back of the Bison chuck.

At this point I still had a 8” diameter plate. I needed to turn it down to slightly under 5”. I used a tool from work that is used to cut face o-ring grooves and can be used to part off the un-needed disk of material from a disk, as my plate had. Once this was done, I finished the OD and now needed to drill the mounting holes.

I did some measuring to find the center of the holes in the original plate from the Atlas and made a life size printout of the 6 holes arrayed around the shoulder that the chuck will mount to. With some careful cutting I fitted the paper to the new plate and transferred the hole positions and drill 3 holes for 1/4” X 20 thread and the alternating holes for unthreaded holes for the mounting bolts.

On the second plate I changed my method a bit. I mounted the plate first to my 4J chuck using the shoulder area and removed the outer disk first. Then I mounted it onto my 6” 3J and then cut the threads faced the registration surface and cleaned up the shoulder and back face. Next I have to check the collet chuck to see if it has any run out and then proceed with making the shoulder and mounting holes to match it. I think I will use the method mentioned on the write up at the cnccookbook.com website. I will let you know how that goes in the future.

Pierre

Last edited: