-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tooling Design & Build Projects

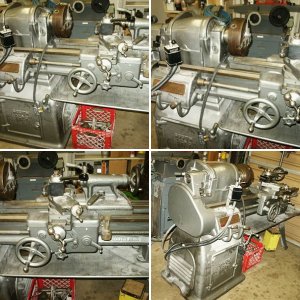

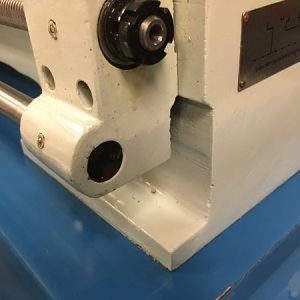

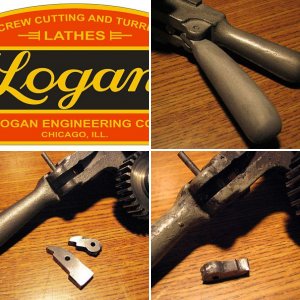

Scraping in all bearing surfaces on my Wards/Logan 10"

PIN

- 44,145

- 73

I've been working on my lathe off and on over the past several weeks or months, but I've been hesitant to start a thread documenting my progress (or lack thereof!) for fear of embarrassing myself. I'm increasingly confident that I'm going to end up with a very precise lathe rather than a very large pile of cast iron dust and tears, so I'm finally willing to share my progress. After creating...

KO-Lee Cutter/Grinder Revamp

PIN

- 33,344

- 93

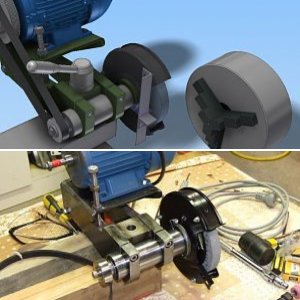

Perhaps you've seen this from other photos... It's a KO-Lee cutter grinder. It's a good platform and the table and all mechanisms are in excellent condition. I don't think this machine was used much in it's lifetime as there are very few signs of wear (hardly any at all really). The motor is the weak link. The bearings are going bad and vibration can be felt in the short shaft. The...

Restoring an old powered hacksaw

Jul 29

- 24,583

- 66

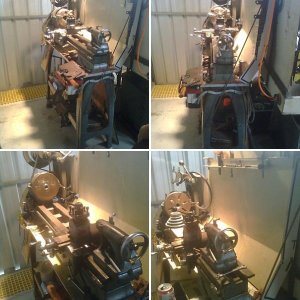

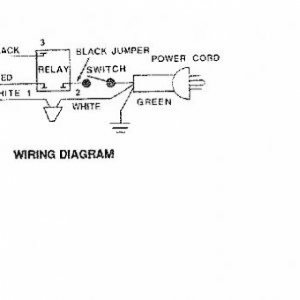

Figured I'd share my restoration project! I've always found these old machines quite cool and when a neighbour offered me a defective one for free, I couldn't say no!  This is the machine as I got it, it runs but won't lower the sawblade so you have to manually push it against the work piece, which becomes quite the challenge and dangerous as heck when it's moving back and forth. The...

This is the machine as I got it, it runs but won't lower the sawblade so you have to manually push it against the work piece, which becomes quite the challenge and dangerous as heck when it's moving back and forth. The...

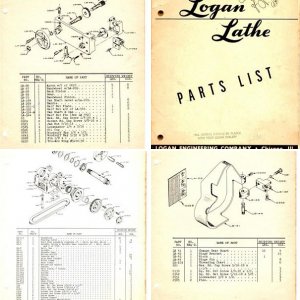

9A project completed

Sep 11

- 36,668

- 67

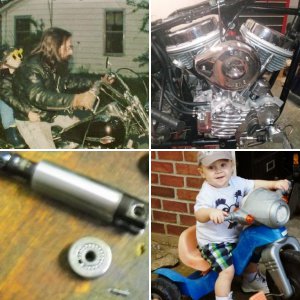

Some of you guys may remember this little crudball I acquired back in April... I had just completed the last project, the Seneca Falls #30 resto-mod,(project of the month) when this lathe found it's way to me via a friend of a friend. My friend, who is also a tool salesman, showed me a pic of this on his phone, which came from his friend, the seller, who now is a retired tool room...

Clausing 1771 Drill Press Restoration

Dec 23

- 24,432

- 31

I picked up a Clausing variable speed drill press from a Craigslist ad. I offered the guy $200.00 and he accepted. The drill press was in decent overall condition, and had a new motor on it. I disassembled the machine and cleaned up and painted everything. Mechanically, it was in very good condition, and the only real repair work I did was to straighten a few of the handle arms. One...

Micrometer Stand

PIN

- 8,614

- 31

Hi guys, here's another project that I wanted to share. This is a pic heavy post but wanted to share each process and op involved. The design came from the [mod edit for link] MakeItFromMetal website. I started out with a 1.5" x 2.5" x 6" piece of 1018 steel. The main block was then milled down flat and square to a finished size of 1.438"H x 2.438"W x 4.5" L. Then the front and sides were...

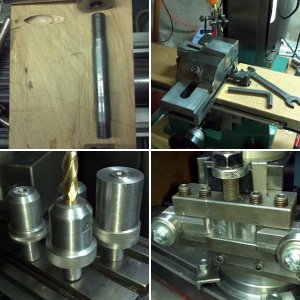

Machinist Jacks

PIN

- 24,858

- 100

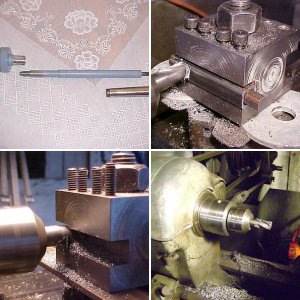

So another tool crossed off the 'To Do' list. Made a pair of machinist jacks, and wanted to post a few pics. I started by turning down some 1.250" diameter Heat Treated 4140 and made the screw/head pieces first. That way I could measure my thread pitch and make sure it was within proper 2A specs. Then I drilled the top of the heads to accept some .375" diameter bushings with a .0005"...

Angle Plate Fixtures for Atlas Horizontal Milling Machine

PIN

- 13,009

- 10

I've been putting off another project for more than year and finally committed to getting started. In order to machine the base casting for the project, I decided to make some angle plate fixtures to bolt down to my Atlas Horizontal Milling Machine. The base casting needs to be flipped several times and spun due to the limited travel 6" x 9" on my Atlas. Here is the mockup renderings I made...

A Straddle Knurler for the Sherline Lathe

PIN

- 177,849

- 104

A Straddle Knurler for the Sherline Lathe The Sherline lathe is far more capable than most people know. I have explored the limits of this amazing lathe for the last 30 years and while I’m sure of what it can do, I am not so sure of what it can’t do because I’m still building tools for it. With the proper turning tools, it will take 0.120” off the diameter in mild steel or 0.200” in aluminum...

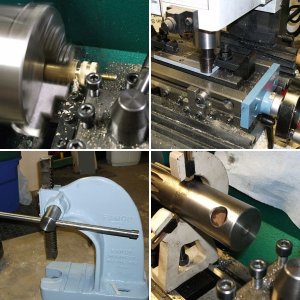

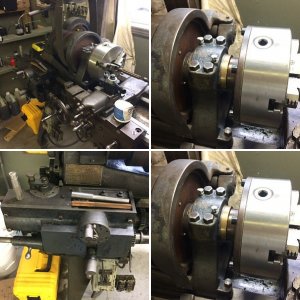

Making a couple of threaded spindle backing plates for my lathe

PIN

- 44,180

- 17

When I sold my Atlas 10F24, I held on to my Bison 5” 3J, as it was fairly new. Naturally I needed to make a new backing plate to mount it onto the new lathe. The old plate was 1 1/2” X 8 while the new spindle is 2 1/4” X 8, so I needed new metal to do this. I recently purchased 2 backing plates from Busy Bee Tools. They are 8” semi raw castings. They are turned to clean off the rough cast...

Clamptite tool

PIN

- 12,492

- 22

I first saw this tool in post #845 of the (Project of the day / what did you do in your shop today)http://www.hobby-machinist.com/attachment.php?attachmentid=63748&d=1383509051. This was posted by Andy Wander. I new when I first saw it that it would be a great little Christmas gift for the men in my family as most of us work with our hands & we're constantly trying to get the most out of what...

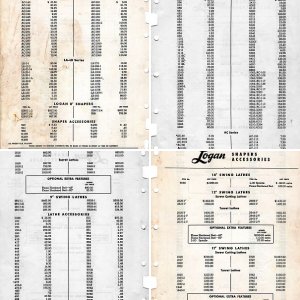

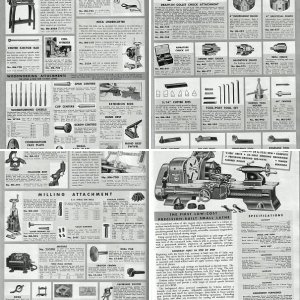

Metal Lathe Accessories is Here to Stay!

Jan 04

- 131

- 4

Hi Everyone, My name is Jared Pilch (Co-Owner of Metal Lathe Accessories) and I sent out the below mass email to as many of our MLA customers as I could find. However, I am sure that I missed some and that is why I am posting it here as well! My bother Jack and I are thrilled to have joined this community and look forward to learning as much as we can! As some of you are aware, Andy...

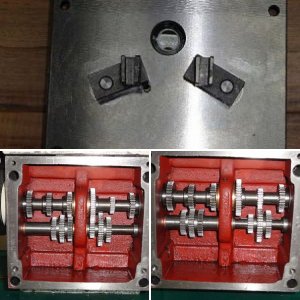

The fixture plates and clamps

May 04

- 13,536

- 28

Hi everyone, I just got started with this little weekend business of mine. I am interested in selling a line of fixture plates and what I call "low-profile" clamps to go along with them. This got started because I told myself that I would make my own fixture plate about a year ago when I needed to machine something that the vice would not really help out with, and I just never got around to...

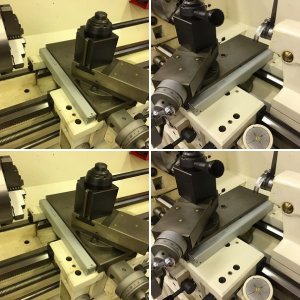

Norman Style QCTP

Sep 15

- 11,654

- 21

I have been using my Norman style QCTP and have sorted out the problems that came up through use. Instead of placing my findings at the end of the very long thread on making it I thought that it would be better to put everything in one place. First off you have to measure the distance from the top of the compound to center line on your lathe. 1 3/16" on my craftsman 12x36 lathe. Next you...

Spider Centering Test Indicator Holder

Mar 31

- 6,926

- 0

Posted this many years ago for my 1340GT, and built another for my ERL-1340 the other day. It uses a test indicator attached a Zero-Set which is normally used in mills for hole centering. Versions of the Zero-Set are on eBay and through Shar's for $20-30. The test indicator holder slides on two bars mounted to the lathe belt cover, so remains in the same position vertically relative to the...

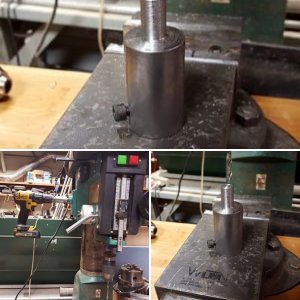

Making A Rotary Broach, By Ulma Doctor

Mar 21

- 18,289

- 32

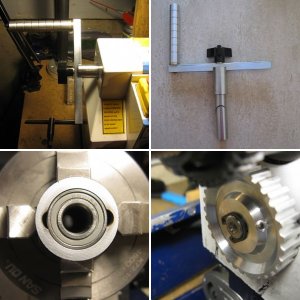

A couple years ago, I made a very quick and dirty rotary broach for a project i was working on in my normal job https://www.hobby-machinist.com/threads/shop-made-rotary-broach-down-and-dirty.48805/ it worked for the purpose it was intended, but i wanted to make an improved version. the new version , i envisioned was precise, robust, and economical. (i priced out a manufactured rotary broach...

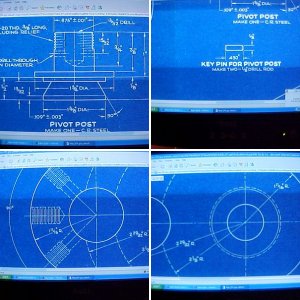

Radius ball turner

Jan 27

- 15,337

- 54

I've been wanting to make a ball turner for quite some time. Well, this past week I finally got a "round 2 it"! My first tool holder attempt caused me to say some things, that I'm glad my son didn't hear... ...but I managed to get it right the second attempt! I first tried mounting the base to the location where the compound rest normally occupies, but soon learned that I would not have...

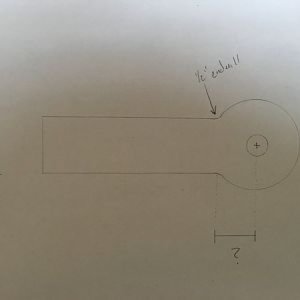

Hand Scraper Design

Dec 05

- 22,590

- 24

I'm monkeying around with making a scraper to repair the cross-slide on the 1440 and would appreciate some input from those that use them. I'm attempting to do this with materials that I have on-hand. The lathe crapped out at very a inconvenient time. I had to take a pass on a decent bit of side work because with the stick-slip, I messed up the first three pieces. So the budget is hurting...

MT3 1" Slitting Saw Arbor

Feb 01

- 7,700

- 30

i started construction on a MT3 slitting saw arbor from materials in the shop. here is the slug of what i believe to be 12L14 mild steel. it was unmarked, but acted like 12L14 i have machined before. it's very nice to turn. the slug was a fraction over 1" in diameter and 7" long. i centerdrilled both ends. i turned the diameter on both ends down to .950". one for the drive dog, the other to...

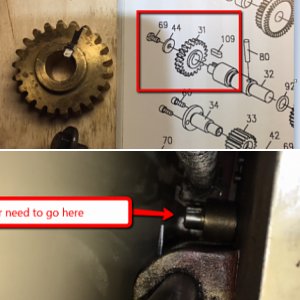

Quick & Dirty Worm Wheel making

Feb 01

- 5,064

- 15

I was trying to make a substantial speed reduction to a small, but very powerful 230 Watt motor to drive a small auger. The motor specs are impressive Mabuchi Motor 12v Rs-775sf 230w 19500 rpm Model : RS-775 18V Weight : 11.9 oz Operating v : 6v - 20v Length of motor : 2.81 in Nominal v : 18v Diameter (with flux ring) : 1.85 in No Load RPM : 19500...

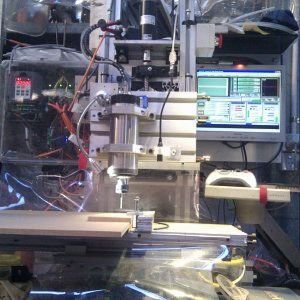

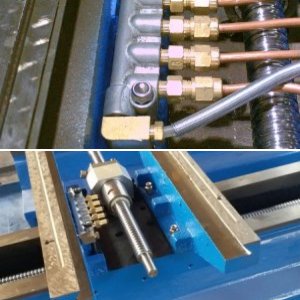

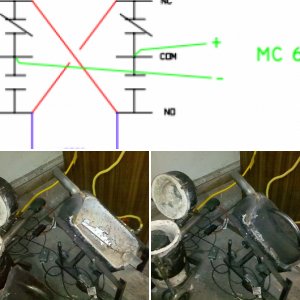

4th axis servo controlled rotary table build

Jan 09

- 7,644

- 53

Hi everyone, I am getting ready to build a 4th axis for my CNC mill. I should be getting the rotary table in the mail in about a week. I will be posting pictures as I go along  . The rotary table is one from eBay. It is of the 8" variety. I believe the brand is CME. The servo and drive is from Leadshine and is 400w. Here are a couple pictures of the servo and drive:

. The rotary table is one from eBay. It is of the 8" variety. I believe the brand is CME. The servo and drive is from Leadshine and is 400w. Here are a couple pictures of the servo and drive:

PM1340 Solid Tool Post for Dorian BXA QC

May 22

- 14,381

- 46

After some hours of use on the Best & Jacobs Full Custom Edition PM1340, I decided it was time to improve rigidity of the toolpost by implementing a solid tool mount as a substitution for the compound when I don't need the function of the compound for normal turning activity. In many ways, what I have done is a derivative of what's been done by Jbolt...