-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Making a Live Center

- Thread starter ddickey

- Start date

- Joined

- May 24, 2012

- Messages

- 395

Had made a pipe center. (used a car wheel bearing and finish pass was done with it mounted on tailstock for accuracy)

http://www.hobby-machinist.com/threads/pipe-center-diy.62156/#post-512365

A live center can be made with no problem. You have to choose (or make) a good bearing (or two) to withstand axial and radial forces with no play.

http://www.hobby-machinist.com/threads/pipe-center-diy.62156/#post-512365

A live center can be made with no problem. You have to choose (or make) a good bearing (or two) to withstand axial and radial forces with no play.

- Joined

- Dec 20, 2012

- Messages

- 9,422

Car bearing might work for pipe but it won't work all that well when you're turning a precision piece.

A live center typically uses multiple single row angular contact bearings, preloaded properly to run smoothly under heavy loads. The bearing fits in the housing and arbor are precise in order to maintain proper internal bearing clearances so if you make one, I hope you can bore to really tight tolerances. The tips are usually ground on the housing of the live center in order to maintain concentricity, although they can be turned with fair accuracy.

I would suggest you contact a bearing supplier and ask for their advice on which bearings to use, spacer dimensions that will go between the bearings and then sort out how you're going to preload them. I would also ask for boring tolerances; typically a line-to-line fit will be somewhere in the 3-5 Micron range. Royal uses a needle bearing on the rear of the internal part of the arbor to handle cantilevered loads; not sure if you want to incorporate that.

Most of the difficulty in a project like this is to sort out the bearing choices. And then of course comes the boring and turning. While most of us could do this sort of thing, it isn't quite as simple as throwing any old bearing in there and expecting it to hold tenths tolerances. Sorry, just the truth.

I cannot post jpegs for some reason but I made one for my Sherline lathe. Fun project.

A live center typically uses multiple single row angular contact bearings, preloaded properly to run smoothly under heavy loads. The bearing fits in the housing and arbor are precise in order to maintain proper internal bearing clearances so if you make one, I hope you can bore to really tight tolerances. The tips are usually ground on the housing of the live center in order to maintain concentricity, although they can be turned with fair accuracy.

I would suggest you contact a bearing supplier and ask for their advice on which bearings to use, spacer dimensions that will go between the bearings and then sort out how you're going to preload them. I would also ask for boring tolerances; typically a line-to-line fit will be somewhere in the 3-5 Micron range. Royal uses a needle bearing on the rear of the internal part of the arbor to handle cantilevered loads; not sure if you want to incorporate that.

Most of the difficulty in a project like this is to sort out the bearing choices. And then of course comes the boring and turning. While most of us could do this sort of thing, it isn't quite as simple as throwing any old bearing in there and expecting it to hold tenths tolerances. Sorry, just the truth.

I cannot post jpegs for some reason but I made one for my Sherline lathe. Fun project.

- Joined

- Mar 3, 2017

- Messages

- 744

Has anyone here made their own rotating dead center?

Thinking it might be a good project.

For my old lathe (uses a non-Morse taper) it's build or do without. So, there's a

back-burner plan to build one. First, though, tool post and motor need to be sorted.

The bearing takes some thrust load, for my small lathe this double-row angular contact

bearing,

<http://www.vxb.com/30-8ZZ-Angular-Contact-Double-Row-Bearing-8x22x11-p/30-8zz.htm>

looks good. VXB.com catalog lists 5200 and 5201 parts as well, with good specs, for

heavier centers.

Two single-row bearings, one angular contact, and one not, would also work. Preloading

is a challenge if you wanted two angular contact units to share the load.

- Joined

- Oct 21, 2017

- Messages

- 504

Car bearing might work for pipe but it won't work all that well when you're turning a precision piece.

A live center typically uses multiple single row angular contact bearings, preloaded properly to run smoothly under heavy loads. .

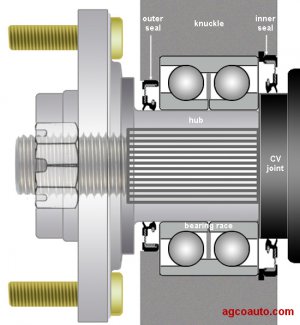

You have neatly described modern car wheel bearings there -

Variants incorporate the seals in the bearing cartridge but pre-loaded angular contact is widely used and is most likely what Cascao used in his

- Joined

- Jul 14, 2017

- Messages

- 2,446

I made one for a friend here is a link, :http://www.hobby-machinist.com/threads/homemade-shop-made-live-center-for-a-lathe.61383/

- Joined

- Dec 20, 2012

- Messages

- 9,422

You have neatly described modern car wheel bearings there -

View attachment 250469

Variants incorporate the seals in the bearing cartridge but pre-loaded angular contact is widely used and is most likely what Cascao used in his

Not knocking Cascao's build in the least.

So, keeping with the subject of this thread, how would you go about making a live center that needs to hold tight tolerances? Not being facetious; I really want to learn so that the next one I make is better.