- Joined

- Feb 7, 2013

- Messages

- 792

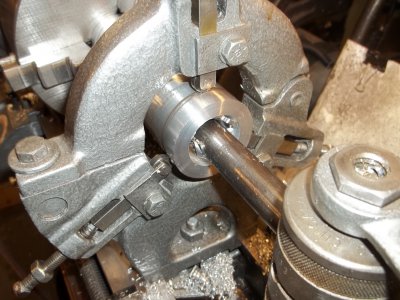

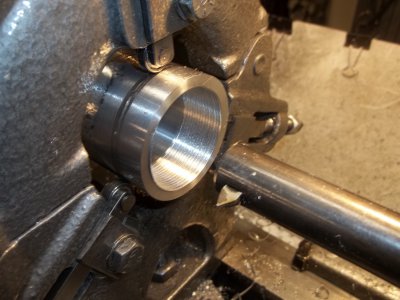

I work with a guy who is a hunter/fisherman he has been looking at Mud Motors to buy but cannot swing the cost I have never seen one except for pictures of them. So I told him I would help out he had a motor and a prop I built everything inbetween. I started with a solid piece of scrap 6" aluminum about 2" long and machined a flange to fit the bolt pattern of the motor I then bored it to 10 under 2" heated up the flange on my BBQ grill and shrunk it onto a 6' aluminum 2' tube made a motor mount and ended up with this to start with.