- Joined

- Dec 29, 2012

- Messages

- 394

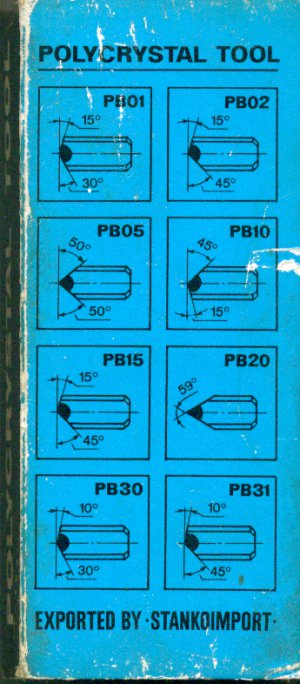

Sometime ago I watched in YouTube a guy machining a ball bearing using an insert that can machine the hardest metal (i.e. the bearing) like butter.

The inserts are called ELBOR, made in Russia and are cheap.

So I searched in ebay, found an auction I put a bet and I won it.

They arrived yesterday so tonight I had to make a holder to test it on the lathe.

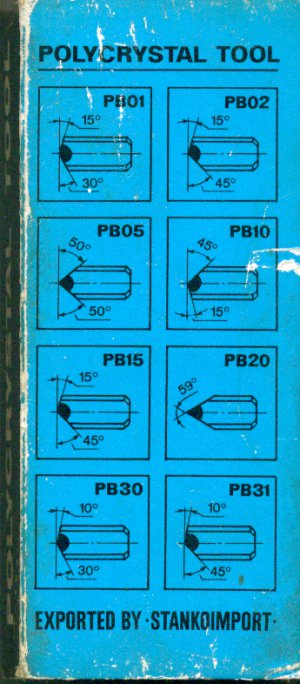

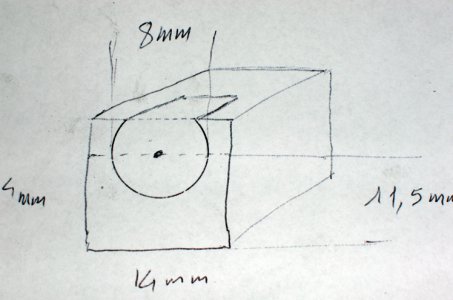

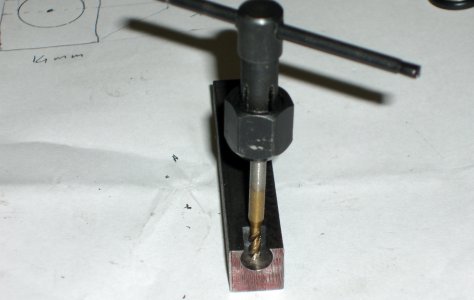

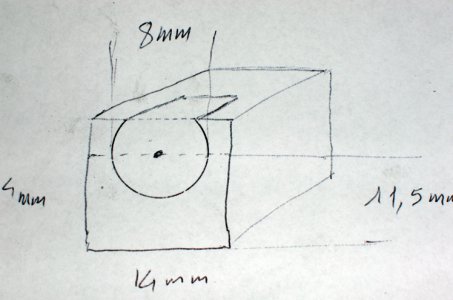

First I made some measurements. They are 8mm X 14 mm cylindrical inserts with an unusual shape and negative rake angle.

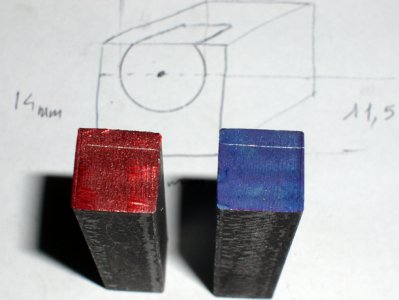

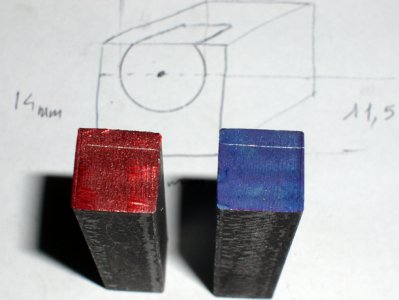

I have some 14 X 14 mm steel bars that I think will be good for insert holders.

The guy in the video that used the inserts has a big lathe that can support large tool holders so he made a conventional tool holder.

For my mini lathe such a holder will protrude so much to the front that will be unusable.

A new approach needed.

I decided to fit the insert in the steel bar at the appropriate height to be exactly at the center of my lathe.

The bars were measured and marked

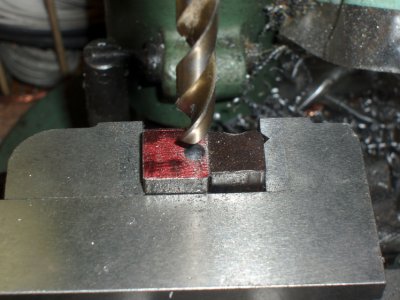

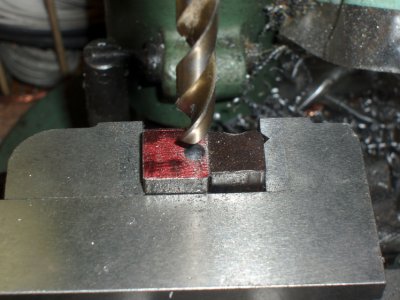

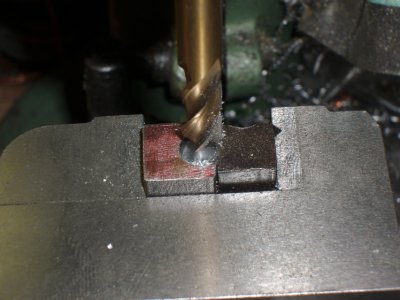

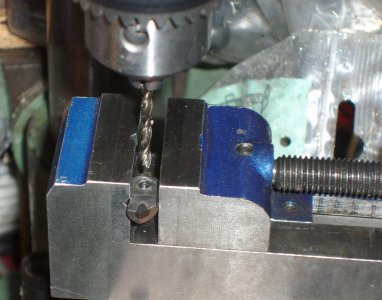

As the hole needed to be offset it would be impossible to drill it to the bar (part of it out of the bar). So I used another bar next to it, supported to a small viseand punched to the center of the required 8mm hole.

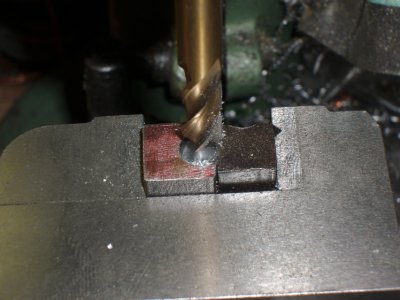

Then I drilled a 4mm pilot hole and the 8mm hole followed

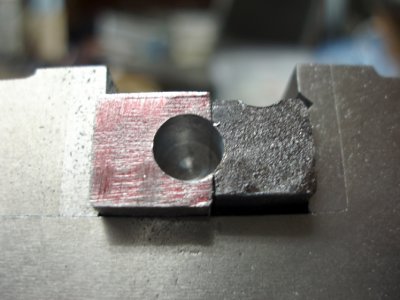

Then I finished it with a 8mm end mill to flatten the bottom

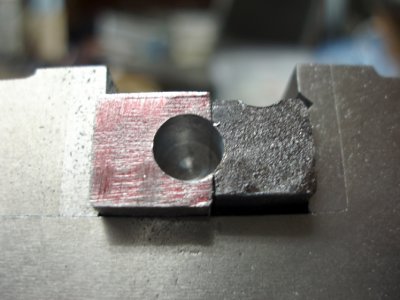

Offset hole ready!

It looks OK

And the insert fits nicely

All I need now is a way to support it in place.

A small bolt on the top would be nice…

A hole to the back of the insert…

Threading the holder..

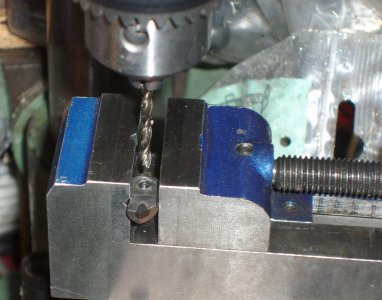

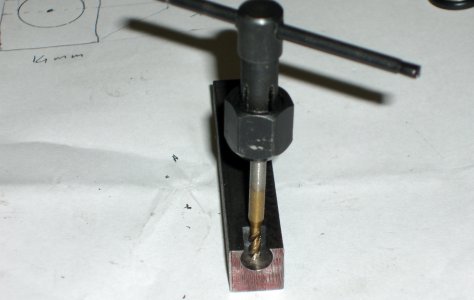

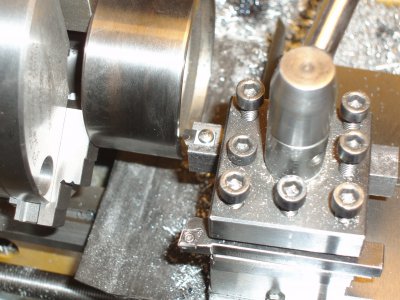

A small screw and my new lathe cutter is ready

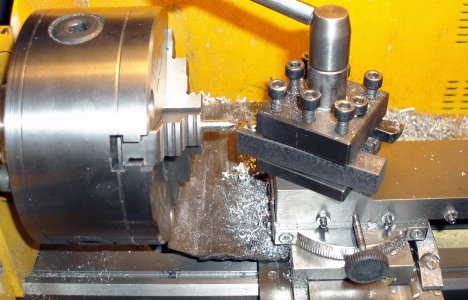

Fits nicely to the tool holder

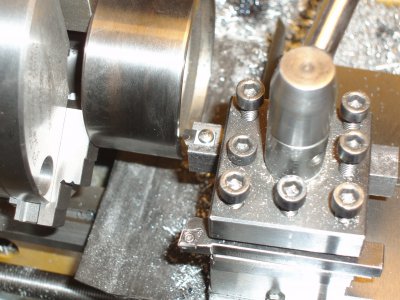

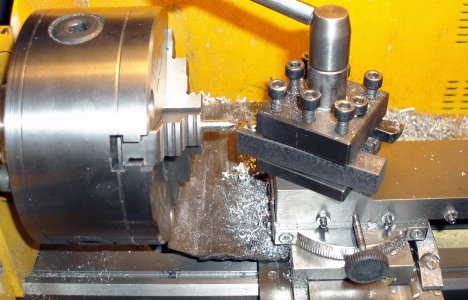

And lets try to machine some bearing… I decided to machine an old wheel bearing at 600 rpm without any lubricants or cutting oil

Piece of cake…

At 600 rpm without any oil or other lubricant it cuts the hard metal better than my carbide inserts cut steel. See the shavings!

I like the near mirror finish !!!

Thanks for reading.

Petros

The inserts are called ELBOR, made in Russia and are cheap.

So I searched in ebay, found an auction I put a bet and I won it.

They arrived yesterday so tonight I had to make a holder to test it on the lathe.

First I made some measurements. They are 8mm X 14 mm cylindrical inserts with an unusual shape and negative rake angle.

I have some 14 X 14 mm steel bars that I think will be good for insert holders.

The guy in the video that used the inserts has a big lathe that can support large tool holders so he made a conventional tool holder.

For my mini lathe such a holder will protrude so much to the front that will be unusable.

A new approach needed.

I decided to fit the insert in the steel bar at the appropriate height to be exactly at the center of my lathe.

The bars were measured and marked

As the hole needed to be offset it would be impossible to drill it to the bar (part of it out of the bar). So I used another bar next to it, supported to a small viseand punched to the center of the required 8mm hole.

Then I drilled a 4mm pilot hole and the 8mm hole followed

Then I finished it with a 8mm end mill to flatten the bottom

Offset hole ready!

It looks OK

And the insert fits nicely

All I need now is a way to support it in place.

A small bolt on the top would be nice…

A hole to the back of the insert…

Threading the holder..

A small screw and my new lathe cutter is ready

Fits nicely to the tool holder

And lets try to machine some bearing… I decided to machine an old wheel bearing at 600 rpm without any lubricants or cutting oil

Piece of cake…

At 600 rpm without any oil or other lubricant it cuts the hard metal better than my carbide inserts cut steel. See the shavings!

I like the near mirror finish !!!

Thanks for reading.

Petros