CH, Mark will get you the info you need, he was an invaluable help with my VFD conversion.

The Hitachi VFD's are very nice and not too difficult to setup.

BTW if you want to do a POD like the one shown above, the enclosure is from McMaster Carr, $28.81. plus shipping.

https://www.mcmaster.com/#7301k37/=1d6pwt1

Or if you are not going to use a tach or mount the tach separately you could consider this less expensive option. $12.00

https://www.automationdirect.com/ad...ghting/Enclosures/Pushbutton_Enclosures/SA111

All the switches 22mm and are from Automation Direct.

Mark has all the part numbers for the switches included in his drawings.

You just need to choose which functions you want, I went with the lighted Emergency Stop and it's great to be able to see the power status from a distance.

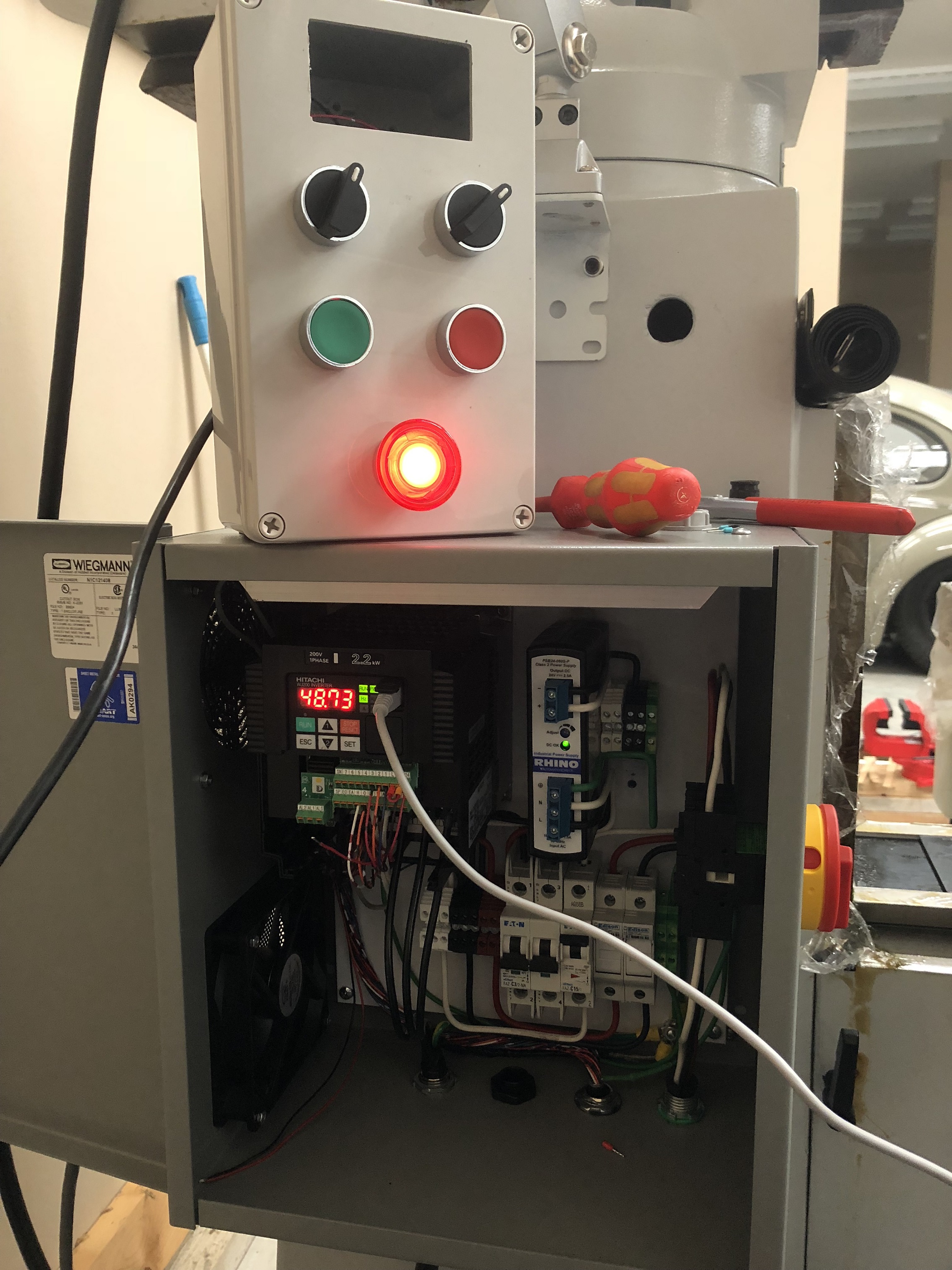

Here is mine, tach not installed yet.

Here's a picture during the programming stage once we got it working.

You probably don't need as much as I have in there as I included everything that I might need in the future and the fan just in case, but probably not needed.

David.