- Joined

- Mar 31, 2023

- Messages

- 16

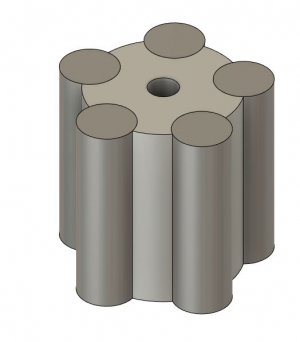

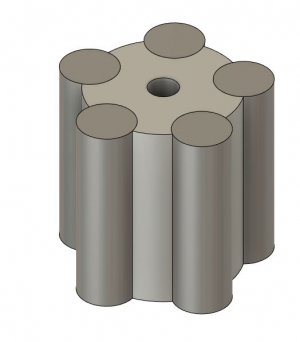

Hi. I want to attach some ground rods to a rotor with no external holes for fasteners. I attached the image of the part below. I do not want to use adhesives to do it.

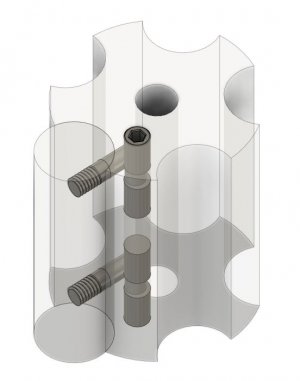

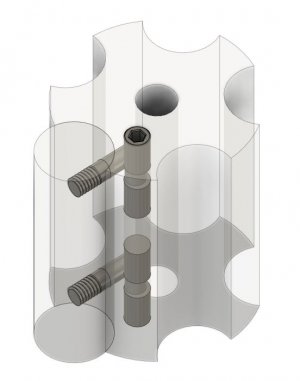

What i was thinking was to screw some smaller rods into the external rods, and then use some camlocking mechanism to draw them into the center rotor. But is there a easier way to do it? I was also thinking of using a lock ring and machine a groove in the rotor and rods for the ring to fit into, but that will not have any force pulling the rods in so i think it will be to loose of a connection.

The part:

My thinking of making a way to fasten the rods to the center rotor:

Also i'm not sure if the cam screws will need to be locked in some way to not loosen up, or if the friction will make sure it stays in place.

What i was thinking was to screw some smaller rods into the external rods, and then use some camlocking mechanism to draw them into the center rotor. But is there a easier way to do it? I was also thinking of using a lock ring and machine a groove in the rotor and rods for the ring to fit into, but that will not have any force pulling the rods in so i think it will be to loose of a connection.

The part:

My thinking of making a way to fasten the rods to the center rotor:

Also i'm not sure if the cam screws will need to be locked in some way to not loosen up, or if the friction will make sure it stays in place.

Last edited: