- Joined

- Mar 26, 2018

- Messages

- 2,724

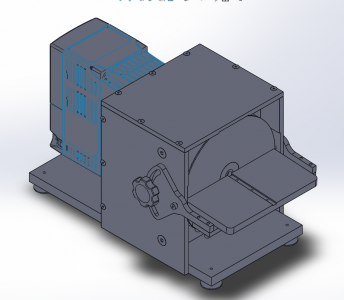

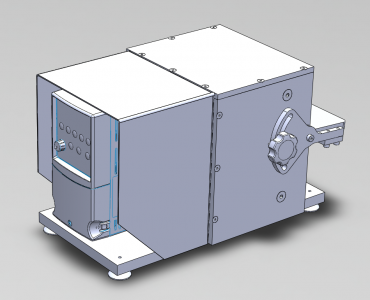

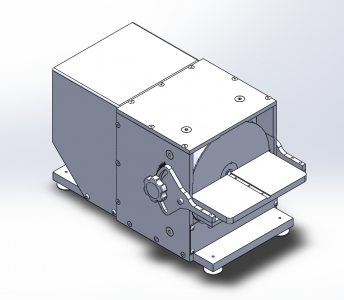

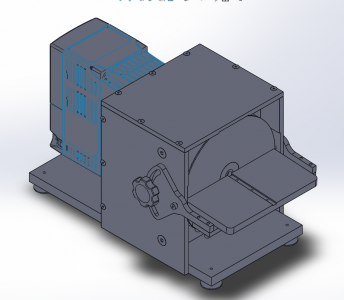

Getting close...

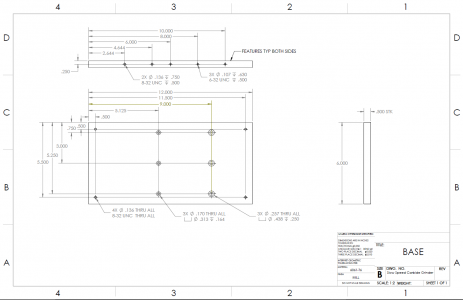

Added fasteners (and related holes) and mounting feet. All that is left is some sheet metal covers for the VFD and lower platter, add mounting holes for the VFD, cable pass thru holes, and drill the pin holes in the lapping disc.

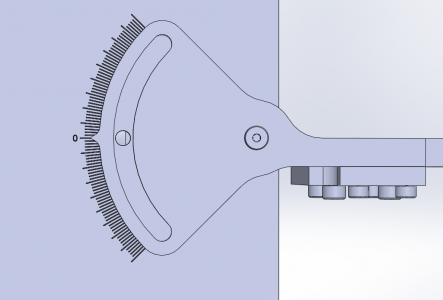

It is held together with #6 flat head cap screws, except for the front bulkhead which uses 1/4" fasteners for stability. The #6 overhang the edge, but I didn't want to go down to #4 screws. The right thing would have been to use thicker side walls, but I have a bunch of 1/4" plate so that is what it is. I'll file the edge of the screw head into a chamfer once it is assembled.

With a bit of planning, I definitely think I could build a drill sharpening jig that mounts onto the fence slot. TBD...

Added fasteners (and related holes) and mounting feet. All that is left is some sheet metal covers for the VFD and lower platter, add mounting holes for the VFD, cable pass thru holes, and drill the pin holes in the lapping disc.

It is held together with #6 flat head cap screws, except for the front bulkhead which uses 1/4" fasteners for stability. The #6 overhang the edge, but I didn't want to go down to #4 screws. The right thing would have been to use thicker side walls, but I have a bunch of 1/4" plate so that is what it is. I'll file the edge of the screw head into a chamfer once it is assembled.

With a bit of planning, I definitely think I could build a drill sharpening jig that mounts onto the fence slot. TBD...