-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Milling machine x-axis power feed recommendation

- Thread starter ARC-170

- Start date

- Joined

- Oct 17, 2018

- Messages

- 922

It came in the mail today. Very quick!

There is NO documentation at all. I'll try installing it in the next few days, but there are some pieces maybe you all can help me identify.

I know what the zip ties and cord holder are. The two screws are for mounting the unit to the bracket. What is the smaller screw for? The bottom, left piece is the rapid traverse button. What are the 2 springs at lower right for? They are not for the limit switches, these are already installed.

Is the top, left piece a cover for the limit switch mechanism (shown right below it)? It seems to just rest on top; there are no screws or anything to attach it.

Check it out! No serial number!

There is NO documentation at all. I'll try installing it in the next few days, but there are some pieces maybe you all can help me identify.

I know what the zip ties and cord holder are. The two screws are for mounting the unit to the bracket. What is the smaller screw for? The bottom, left piece is the rapid traverse button. What are the 2 springs at lower right for? They are not for the limit switches, these are already installed.

Is the top, left piece a cover for the limit switch mechanism (shown right below it)? It seems to just rest on top; there are no screws or anything to attach it.

Check it out! No serial number!

- Joined

- Oct 17, 2018

- Messages

- 922

One thing to keep in mind is replacement parts and warranty issues. Align parts are easy to come by. Not sure about anything sold on eBay.

I have 2 Align power feeds on my mill. After 5 years no issues.

When I was looking, I saw several companies on Ebay and elsewhere selling what appeared to be the exact same device, all for either very similar prices. The pictures were all the same and so was the warehouse they shipped out of. I suspect the same factory in China makes these for everyone. I figure I can find a clone and order parts from there.

I thought of ordering a better-known brand, but this was abut $150 shipped. I could be throwing money away, so we'll see how this holds up. I'm a home shop DIY'er, so I think this will suit my needs. I'll keep you all updated.

- Joined

- Feb 17, 2013

- Messages

- 4,406

Don't have any idea what the springs are for. Often an item of retrofit hardware will have parts for installation on several different styles of machines. Bummer that there's no instructions!

The label on the cover sure makes it look like it's supposed to go over the limit switch ... possibly to protect the cable exit??? The (older) Align unit on my mill did not have any such cover.

The label on the cover sure makes it look like it's supposed to go over the limit switch ... possibly to protect the cable exit??? The (older) Align unit on my mill did not have any such cover.

- Joined

- Jul 29, 2014

- Messages

- 2,737

I have installed 3 of these so far, an Align, a Bestline and something that wasn’t either of those. Two were X axis, one was Z axis.

From direct experience, I can tell you these is not an iota of difference in these units. The instructions are equally deplorable and basically useless. Throw them away and start figuring it out. The main issue that comes up is how many shims to use and how would you know. I’ve tried analytic measurement and trial and error, lots of error. Neither is particularly satisfactory, especially because the criteria for success is not clear. Good luck, eventually you will arrive at a compromise between smoothness and what you hope is minimum wear.

If you are replacing a Bridgeport branded power feed, be aware that, at least in my case, there was a shaft extension required that was something like $120...when it came, I could have made it easily for zilch.

So I suggest getting the higher torque model at the lowest cost possible.

From direct experience, I can tell you these is not an iota of difference in these units. The instructions are equally deplorable and basically useless. Throw them away and start figuring it out. The main issue that comes up is how many shims to use and how would you know. I’ve tried analytic measurement and trial and error, lots of error. Neither is particularly satisfactory, especially because the criteria for success is not clear. Good luck, eventually you will arrive at a compromise between smoothness and what you hope is minimum wear.

If you are replacing a Bridgeport branded power feed, be aware that, at least in my case, there was a shaft extension required that was something like $120...when it came, I could have made it easily for zilch.

So I suggest getting the higher torque model at the lowest cost possible.

- Joined

- Jul 29, 2014

- Messages

- 2,737

The springs mentioned are, I believe, for the end travel stops. They fit on the plunger looking thing that contacts the switch and provide some cushioning, since the transition to stopped is not instantaneous.

- Joined

- Oct 17, 2018

- Messages

- 922

The unit actually installed fine (so far). It has the two screws that fit in slots and this is adjusted in and out along the X axis to mesh the gears. The gear fit right on the end of the leadscrew. The brackets also fit pretty well. I didn't crank them down too tight since I saw another post that said to be careful or the brackets will crack. I may make something to attach this better.I have installed 3 of these so far, an Align, a Bestline and something that wasn’t either of those. Two were X axis, one was Z axis.

From direct experience, I can tell you these is not an iota of difference in these units. The instructions are equally deplorable and basically useless. Throw them away and start figuring it out. The main issue that comes up is how many shims to use and how would you know. I’ve tried analytic measurement and trial and error, lots of error. Neither is particularly satisfactory, especially because the criteria for success is not clear. Good luck, eventually you will arrive at a compromise between smoothness and what you hope is minimum wear.

If you are replacing a Bridgeport branded power feed, be aware that, at least in my case, there was a shaft extension required that was something like $120...when it came, I could have made it easily for zilch.

So I suggest getting the higher torque model at the lowest cost possible.

I do need to make some sort of adapter for the limit switches. The screw holes don't align and it needs to stick out farther.

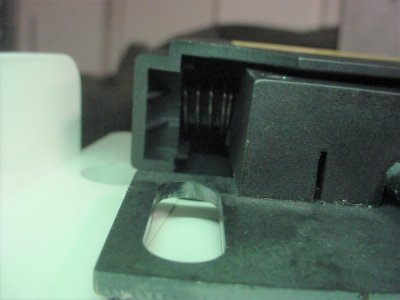

Those already have springs. But, I figured it out. They go inside the black plastic cover over the plungers on the plunger. They hold the cover on the plunger unit. Here's a view looking at the plunger assembly from the bottom. You can see the spring.The springs mentioned are, I believe, for the end travel stops. They fit on the plunger looking thing that contacts the switch and provide some cushioning, since the transition to stopped is not instantaneous.

- Joined

- Jul 29, 2014

- Messages

- 2,737

That does not sound like the units I installed.It has the two screws that fit in slots and this is adjusted in and out along the X axis to mesh the gears.

- Joined

- Oct 16, 2019

- Messages

- 6,574

I wouldn't think a unit designed for a BP type mill would work on a RF30, it's not just the mounting but also the interface to the lead screw.

I’m in the process of putting a BP-style drive on my RF30 clone.