You are a patient individual, I'd have tools all over by now!Washing the Toyota at the moment

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Millrite Moving Methods?

- Thread starter Dave Bonzo

- Start date

- Joined

- Nov 22, 2022

- Messages

- 403

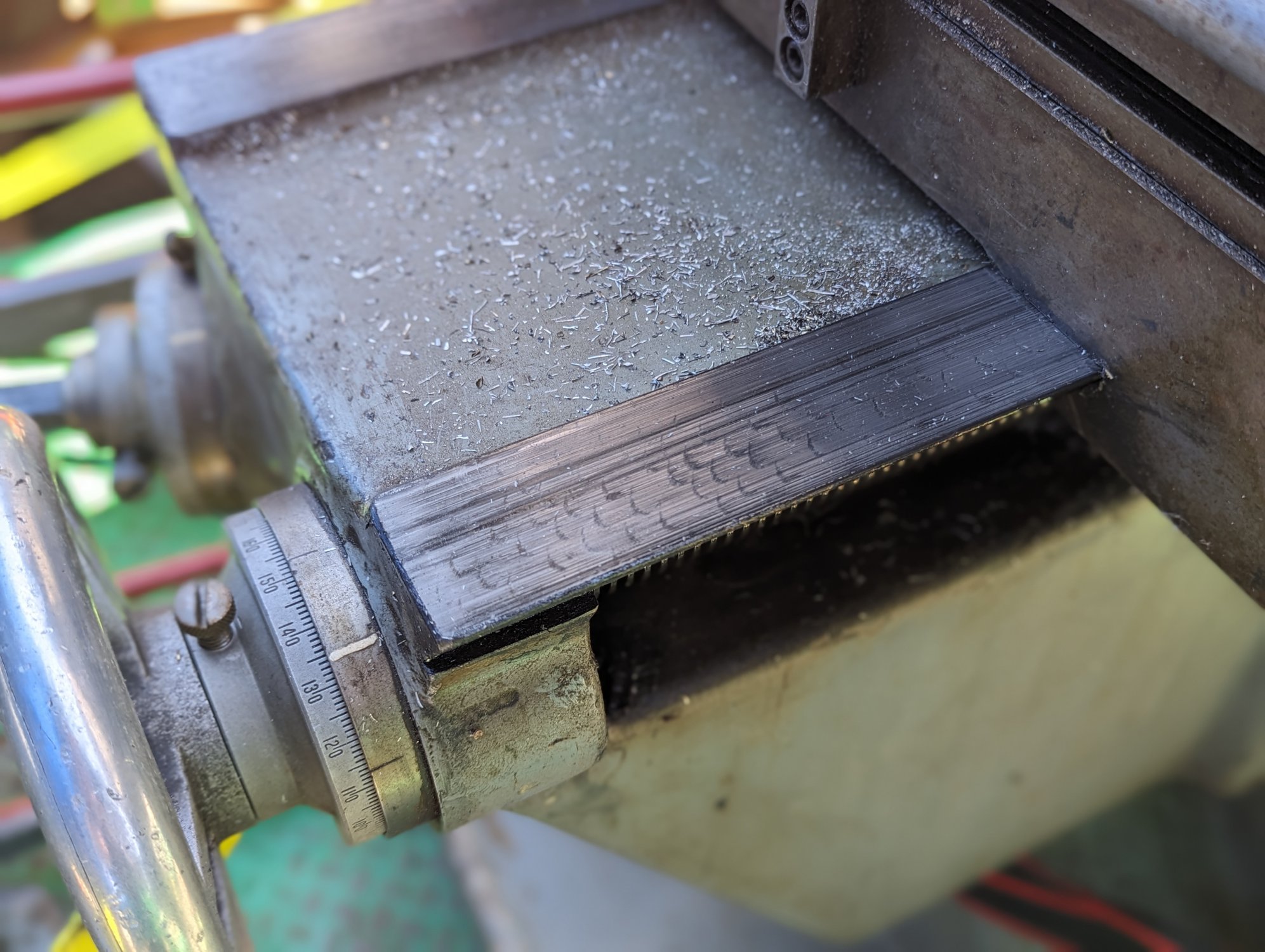

That's called "Hand Scraped" That means that someone at the factory actually took the time to make sure it was as close to flat as humanly possible. On some very cheap machines it is supposedly done for oil retention and to give it the look of hand scraping. All high quality machines even today are "Hand Scraped"Pictured: Funny-looking marks.

View attachment 451653

That's literally the only picture I have, right now...but I'll get some more in a few. Washing the Toyota at the moment, so I'm not untarping anything until the water spray goes away. But it doesn't look so terrible, there.

That means it's not worn out. There should be similar scraping marks on the column. Keep way oil on those surfaces and it will last you a long time. Also, don't forget to lubricate Z axis lead screw, when that gets dry, the knee tends to stick and jump when lowering. When it is lubricated well, it should glide easily up and down.Pictured: Funny-looking marks.

View attachment 451653

That's literally the only picture I have, right now...but I'll get some more in a few. Washing the Toyota at the moment, so I'm not untarping anything until the water spray goes away. But it doesn't look so terrible, there.

- Joined

- Apr 9, 2023

- Messages

- 163

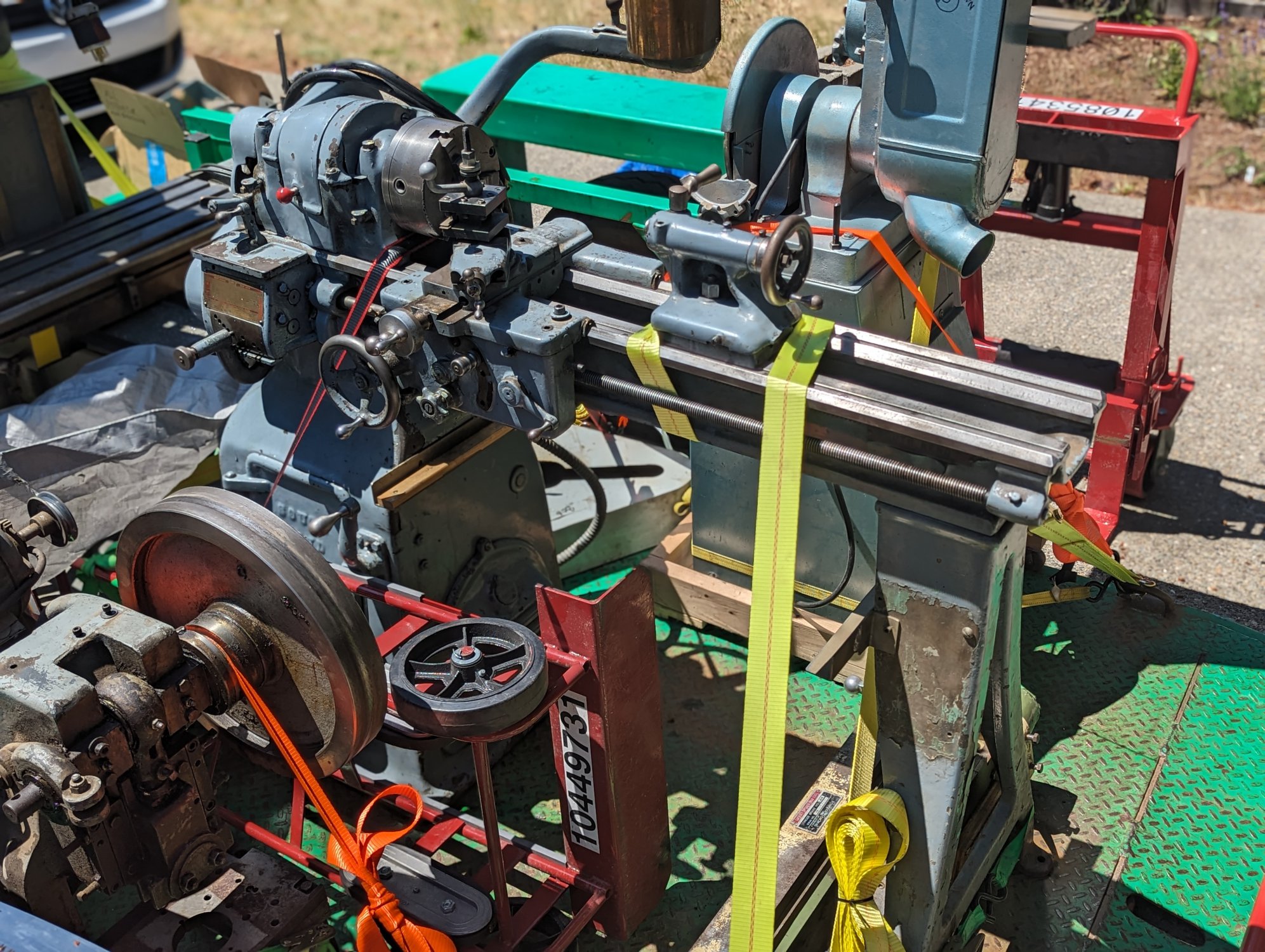

Pictured: Le Millrite.

Pictured: Entirely too much stuffs.

Believe it or not, some of the ratchet straps have already been removed; these are just the primary ones that are left over.

Pictured: Lathe...and other things, again.

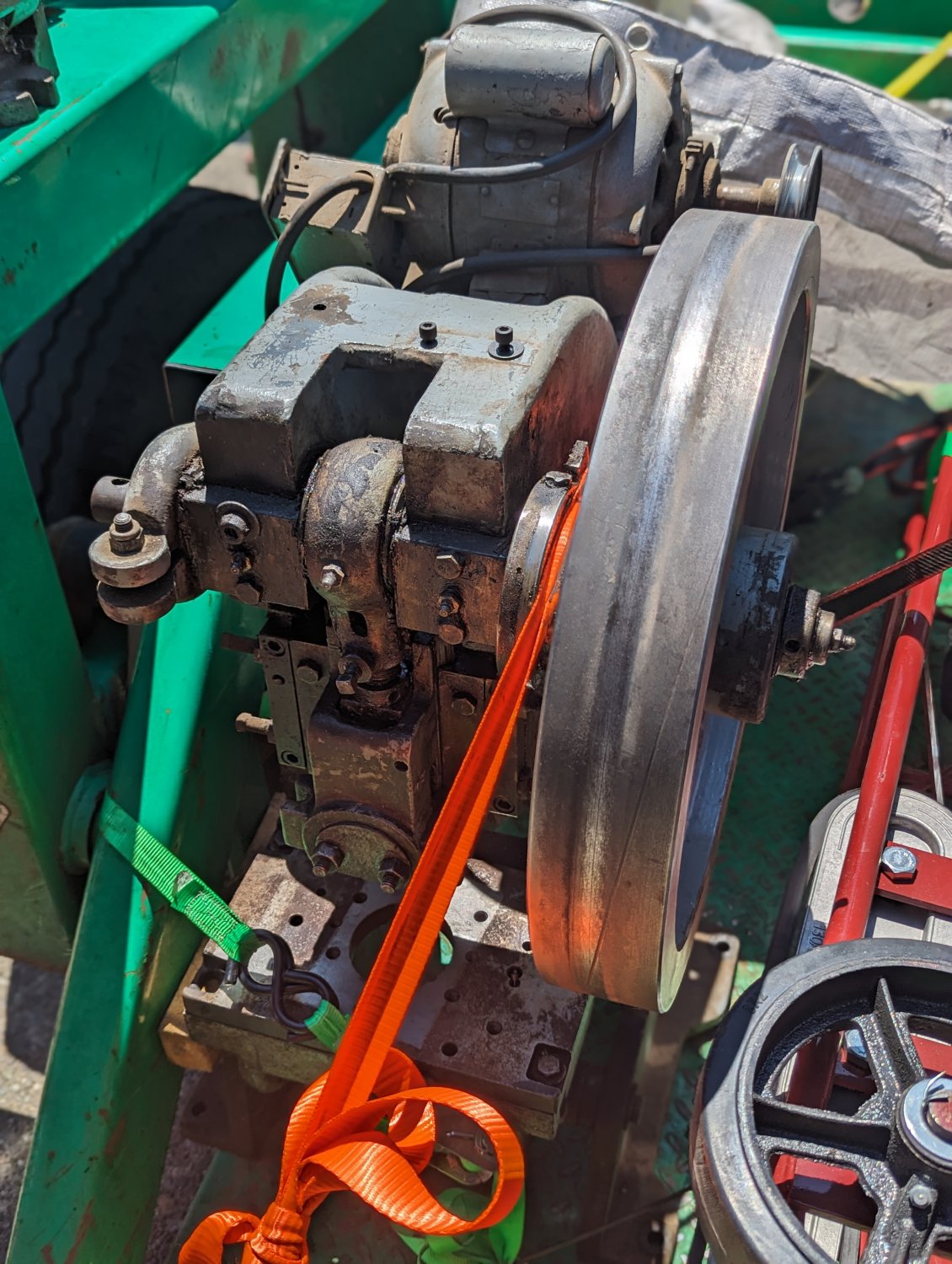

Pictured: Baby punch press.

Pictured: Free vise.

Pictured: More mill-bits.

That's all I took; it got hot outside and I'm still rearranging thinking in the garage. Everything needs a bath and it's all in a state of partial disassembly, but it's mostly there.

Pictured: Entirely too much stuffs.

Believe it or not, some of the ratchet straps have already been removed; these are just the primary ones that are left over.

Pictured: Lathe...and other things, again.

Pictured: Baby punch press.

Pictured: Free vise.

Pictured: More mill-bits.

That's all I took; it got hot outside and I'm still rearranging thinking in the garage. Everything needs a bath and it's all in a state of partial disassembly, but it's mostly there.

Last edited:

- Joined

- Nov 22, 2022

- Messages

- 403

Good Job Everybody! Especially you Dave!

Looks good, Let me find my Drool cup! I love those kind of deals, Those don't come around too often!

Looks good, Let me find my Drool cup! I love those kind of deals, Those don't come around too often!

- Joined

- Apr 9, 2023

- Messages

- 163

It's like a shop in a box!

I could have gotten more, but I was out of room and weight. There's still a cylindrical grinder, a pantograph, a gear hobber, two punch presses, etc, etc. But yeah, I think it was a decent score. The lathe looks rough but it passed my initial inspection...and the fact that this stuff came from the shop of a guy that made toy trains for seventy years kind of tells me that it's been taken care of. Every single piece we loaded, he took twenty minutes to tell me all about what to do and not do with it, what oil it likes best, when he bought it, where it came from, how many parts he'd made on it, etc.

- Joined

- Apr 23, 2018

- Messages

- 6,590

Looks to me like you've got a lot to be happy about, Dave!

- Joined

- Apr 9, 2023

- Messages

- 163

Looks to me like you've got a lot to be happy about, Dave!

I'm pretty stoked, to be honest. I've played with all of this stuff before, but I've never actually had it at hand long enough to truly learn it. Hopefully this is the start of that journey.

- Joined

- Apr 9, 2023

- Messages

- 163

Pictured: One down...four to go.

To be honest, I'm not sure that it'll stay right here...but this is kind of a decent spot for it. I'll probably shove it around a bit tomorrow and remove some of the rack storage that's on the wall, there...or turn it into a tool shelf. Hmmm...

To be honest, I'm not sure that it'll stay right here...but this is kind of a decent spot for it. I'll probably shove it around a bit tomorrow and remove some of the rack storage that's on the wall, there...or turn it into a tool shelf. Hmmm...