- Joined

- Jun 14, 2016

- Messages

- 5

Hello All! Thanks for all the patient feedback without any batting about my ears.

As an utter newb I did assume that a 7in lathe could turn a 7in piece of stock (not that I can turn anything more than about 10mm right now, ha!). The largest project I have in mind is 108mm OD alu but that would need to be turned on a larger lathe to get good results anyway.

As I move along, I will have a million more question for everyone, but for now I will start small and get creative as I go along. The LMS extension kit adds 1.0in which is not insignificant for U$75.

First project is a base for a LED goose neck light so I can see what I am doing on future projects. Basically, 2in OD disc at 0.75 depth, with a rebate to hold the magnet. I think threading is a little outlandish for me at this time so I will cheat and use a tap.

Great intro article link from Brino. Nice simple work around from kd4gij. Thanks Again!

As an utter newb I did assume that a 7in lathe could turn a 7in piece of stock (not that I can turn anything more than about 10mm right now, ha!). The largest project I have in mind is 108mm OD alu but that would need to be turned on a larger lathe to get good results anyway.

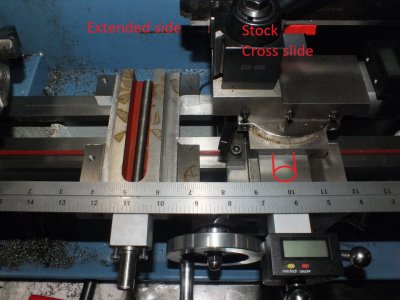

As I move along, I will have a million more question for everyone, but for now I will start small and get creative as I go along. The LMS extension kit adds 1.0in which is not insignificant for U$75.

First project is a base for a LED goose neck light so I can see what I am doing on future projects. Basically, 2in OD disc at 0.75 depth, with a rebate to hold the magnet. I think threading is a little outlandish for me at this time so I will cheat and use a tap.

Great intro article link from Brino. Nice simple work around from kd4gij. Thanks Again!