- Joined

- Feb 25, 2021

- Messages

- 3,129

Hopefully Ok that I'm posting a bunch of different threads on different machines that I'm rebuilding. I hope to make each thread sort of a running commentary, starting with when I acquired the machine, on each machine but it'll take a while to get caught up to current status on each machine.

The Monarch CK taught me that I really enjoyed working on the older machines. Now admittedly I have no clue what I'm doing but figuring it out is a big part of the fun. After the CK and 10EE, I had lusted after a longer bed machine. 20" c-to-c on the 10EE, and 30" c-to-c on the CK, but some of the farm projects I envision could go quite a bit longer. A Monarch 61 from the mid 50s was what I was looking for. I'd been watching for one of those for a few years. The good ones go extremely fast.

In that search I came across an ad on FB marketplace for a Monarch 612 for sale in NE Ohio, about 6 hours drive. I made arrangements to go look at it with my trailer in tow. I was given to believe it was a 16" swing machine with a 10HP motor, 50" center to center. The typical Monarch serial number placard was a 'government sale' version so didn't have the usual swing and c-to-c length info in the ad's picture.

I drove up to NE Ohio and spent the night in a hotel with arrangements for the next morning. Turned out to be this large machine old manual machine shop, bunch of hue lathes and a few mills, along with a huge heat-treat furnace. They had found a problem with the lathe testing it out the day before and were working pretty intensively on fixing it. The feed mechanism was not working in the apron, they had the apron off and were looking at swapping aprons with another lathe.

Three guys, including the shop owner, spent most of the morning working on the machine with no commitment from me other than to see how it worked out. I did get to see the lathe running and everything working except for the feed. They got the parts replaced and were working on reassembling, but it was nearing noon, and with a 6 hour drive plus an hour time change, I was getting concerned as driving pulling a 30' gooseneck after dark is not something I care to do. I talked to the owner and we agreed on a *substantial* price reduction for me to take it without the apron re-installed, but all parts and a three-jaw chuck. They also had all of the documentation for the lathe since it was originally sold by Monarch to a government contractor for $33,000 in 1967. With hotel and diesel fuel costs I got it for less than a 1/10th of that. The shop owner obviously felt bad that they'd spent my time working on it, and wanted to be sure I went away happy. Obviously someone who understands that his customers matter.

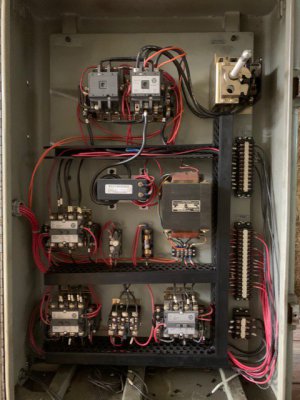

So upon getting home and really looking at the documentation, etc, it was clear this was a Monarch 612-2516. 25" swing over bed, 16" swing over carriage, 48" center to center. 20HP motor, everything wired 440v. Actually a total of four three-phase motors, main drive motor, rapid traverse motor, hydraulic pump motor, and coolant pump.

Estimated weight is about 9000 lbs, documented weight is nearly 12000 but that included a no-longer present tracer bed along the back. I built myself a large gantry to unload this. Even though the crane was engineered, hoisting anything that heavy is nerve wracking to say the least. Note that the carriage apron and tailstock, at least 1000lbs worth, where removed prior to hoisting to reduce the weight. (Overhead lifting equiment should be engineered with a 5x safety factor.)

The Monarch CK taught me that I really enjoyed working on the older machines. Now admittedly I have no clue what I'm doing but figuring it out is a big part of the fun. After the CK and 10EE, I had lusted after a longer bed machine. 20" c-to-c on the 10EE, and 30" c-to-c on the CK, but some of the farm projects I envision could go quite a bit longer. A Monarch 61 from the mid 50s was what I was looking for. I'd been watching for one of those for a few years. The good ones go extremely fast.

In that search I came across an ad on FB marketplace for a Monarch 612 for sale in NE Ohio, about 6 hours drive. I made arrangements to go look at it with my trailer in tow. I was given to believe it was a 16" swing machine with a 10HP motor, 50" center to center. The typical Monarch serial number placard was a 'government sale' version so didn't have the usual swing and c-to-c length info in the ad's picture.

I drove up to NE Ohio and spent the night in a hotel with arrangements for the next morning. Turned out to be this large machine old manual machine shop, bunch of hue lathes and a few mills, along with a huge heat-treat furnace. They had found a problem with the lathe testing it out the day before and were working pretty intensively on fixing it. The feed mechanism was not working in the apron, they had the apron off and were looking at swapping aprons with another lathe.

Three guys, including the shop owner, spent most of the morning working on the machine with no commitment from me other than to see how it worked out. I did get to see the lathe running and everything working except for the feed. They got the parts replaced and were working on reassembling, but it was nearing noon, and with a 6 hour drive plus an hour time change, I was getting concerned as driving pulling a 30' gooseneck after dark is not something I care to do. I talked to the owner and we agreed on a *substantial* price reduction for me to take it without the apron re-installed, but all parts and a three-jaw chuck. They also had all of the documentation for the lathe since it was originally sold by Monarch to a government contractor for $33,000 in 1967. With hotel and diesel fuel costs I got it for less than a 1/10th of that. The shop owner obviously felt bad that they'd spent my time working on it, and wanted to be sure I went away happy. Obviously someone who understands that his customers matter.

So upon getting home and really looking at the documentation, etc, it was clear this was a Monarch 612-2516. 25" swing over bed, 16" swing over carriage, 48" center to center. 20HP motor, everything wired 440v. Actually a total of four three-phase motors, main drive motor, rapid traverse motor, hydraulic pump motor, and coolant pump.

Estimated weight is about 9000 lbs, documented weight is nearly 12000 but that included a no-longer present tracer bed along the back. I built myself a large gantry to unload this. Even though the crane was engineered, hoisting anything that heavy is nerve wracking to say the least. Note that the carriage apron and tailstock, at least 1000lbs worth, where removed prior to hoisting to reduce the weight. (Overhead lifting equiment should be engineered with a 5x safety factor.)

Last edited: