- Joined

- Mar 25, 2013

- Messages

- 4,645

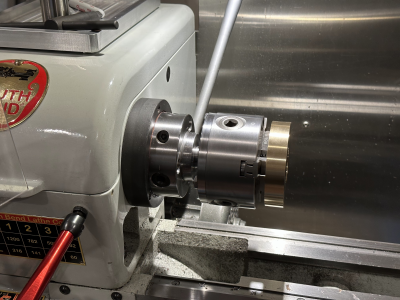

So I put a collar on the baby Bison:

This is mounted on a 6" D1-3 back plate sourced from Grizzly. Unfortunately it showed .003" runout! After some inspection I realized there was some slop in the factory taper .

.

I measured about .002 slop in the taper implying that it was oversize on the radius by .001". Since a D1 taper is 8:1 I needed to take .008 off the flat mounting face. After doing this the taper was tight and actually needs a bump with a mallet to come off. I then re-machined the mounting boss on the front to fit the chuck.

The result is about .0004 of runout! This is repeatable if I remove and reinstall the chuck. Finally! I think I am going to leave the collar since it helps to turn the chuck by hand and I can't see it interfering with anything. It does add to the rotational mass which can be good and bad.

I should also note that this has cured the chatter problems.

This is mounted on a 6" D1-3 back plate sourced from Grizzly. Unfortunately it showed .003" runout! After some inspection I realized there was some slop in the factory taper

I measured about .002 slop in the taper implying that it was oversize on the radius by .001". Since a D1 taper is 8:1 I needed to take .008 off the flat mounting face. After doing this the taper was tight and actually needs a bump with a mallet to come off. I then re-machined the mounting boss on the front to fit the chuck.

The result is about .0004 of runout! This is repeatable if I remove and reinstall the chuck. Finally! I think I am going to leave the collar since it helps to turn the chuck by hand and I can't see it interfering with anything. It does add to the rotational mass which can be good and bad.

I should also note that this has cured the chatter problems.