- Joined

- Jan 2, 2014

- Messages

- 8,862

Hi Garth,

Welcome to the site!

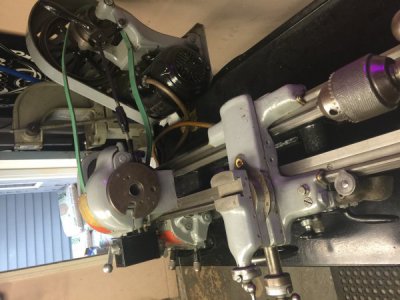

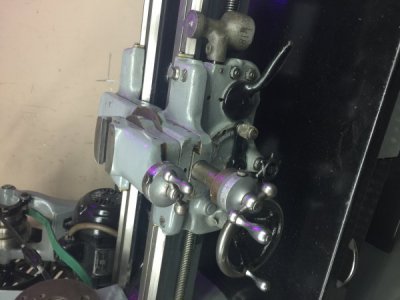

I agree with what's stated above. Clean it, lube it and use it.

Then you'll know if the short bed will do everything you want.

Make the decision on full restore later, once you know it better.

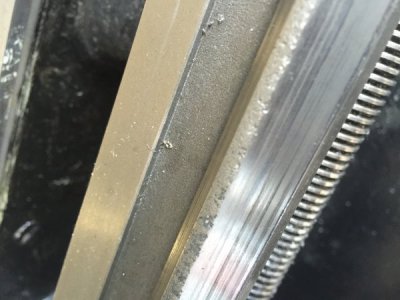

By the way, it's nice to see so many photos. Thanks for that!

Good luck and let us know how it goes.

-brino

Welcome to the site!

I agree with what's stated above. Clean it, lube it and use it.

Then you'll know if the short bed will do everything you want.

Make the decision on full restore later, once you know it better.

By the way, it's nice to see so many photos. Thanks for that!

Good luck and let us know how it goes.

-brino