- Joined

- Dec 13, 2016

- Messages

- 142

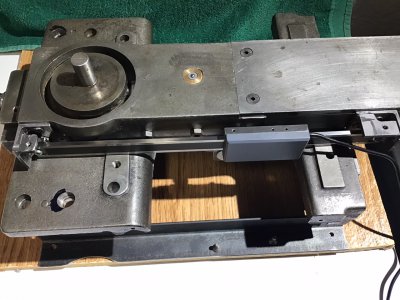

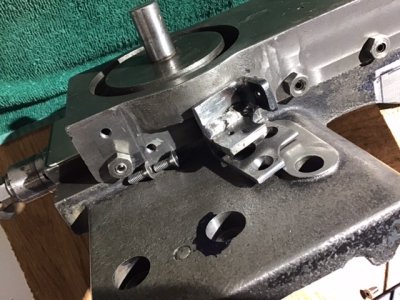

Well finally got the iGaging scale mounted to the crossslide. I can now paint the casting and do final assembling. My new (to me) milling machine was put to good use milling flat surfaces to mount chip guard, shield and making brackets.

The hardest thing was drilling 1/8” hole at the end of of the shorten 12” scale. Many hours drill/sharping cobalt M42 drill bits. Was looking at ordering a carbide endmill. Ending up using a 1/8” tungsten carbide cutting bit from Lowes on my DreMel tool. Five minutes job was done.

The hardest thing was drilling 1/8” hole at the end of of the shorten 12” scale. Many hours drill/sharping cobalt M42 drill bits. Was looking at ordering a carbide endmill. Ending up using a 1/8” tungsten carbide cutting bit from Lowes on my DreMel tool. Five minutes job was done.

Attachments

-

1400105F-895C-4F57-B97B-85976A5429BD.jpeg463.4 KB · Views: 15

1400105F-895C-4F57-B97B-85976A5429BD.jpeg463.4 KB · Views: 15 -

1B186ACE-5151-43FB-9DA0-DCD8E03B64DD.jpeg424 KB · Views: 15

1B186ACE-5151-43FB-9DA0-DCD8E03B64DD.jpeg424 KB · Views: 15 -

20028088-7C32-4C5C-99F9-37BA6AE0BA69.jpeg130.5 KB · Views: 15

20028088-7C32-4C5C-99F9-37BA6AE0BA69.jpeg130.5 KB · Views: 15 -

6CF68DDB-6EEF-4B60-B633-C0430416E473.jpeg111.9 KB · Views: 14

6CF68DDB-6EEF-4B60-B633-C0430416E473.jpeg111.9 KB · Views: 14 -

FC41FCE6-B86F-487C-BA7F-B34C39F2D2BC.jpeg98.3 KB · Views: 13

FC41FCE6-B86F-487C-BA7F-B34C39F2D2BC.jpeg98.3 KB · Views: 13