- Joined

- Mar 2, 2018

- Messages

- 232

I hooked it all back up and took it for a spin. Ambient is 64 F, dew point is 64 F, humidity is 99%. The heaters came on, and stayed on, and stayed on, and stayed on. Hmmm. I happen to have bought a FLIR One, so I went out there to see what was going on.

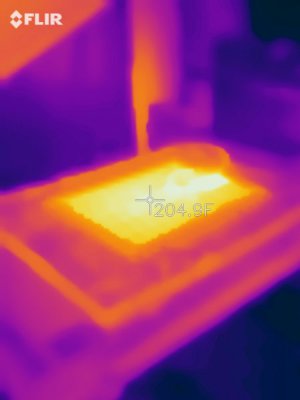

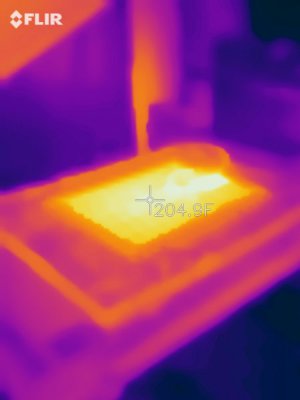

The heaters get up a little above 200 F.

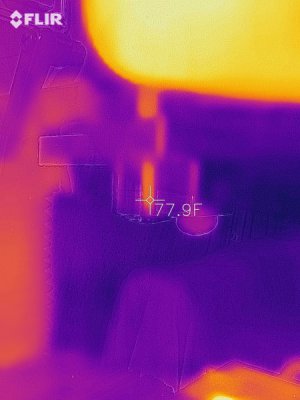

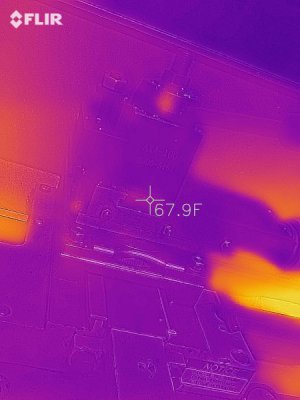

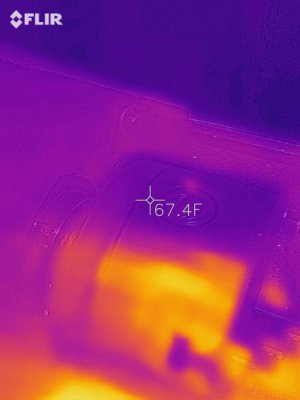

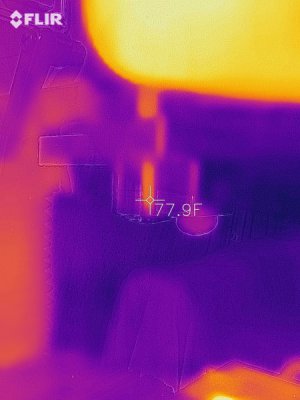

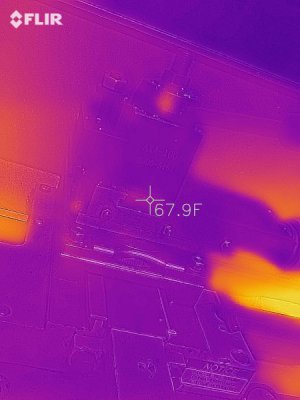

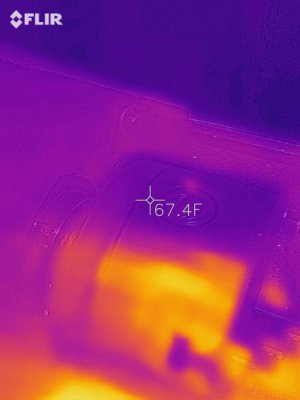

After soaking for a few minutes, every surface of concern was warm enough to stave off condensation with a dew point of 64 F.

As far as I could tell, the heaters were never going to turn off, so I removed six Phillips screws and two zip screws and brought the whole shebang back in here for round three. I obviously need to get a lot more sophisticated to make this work well, which is a fact I'm balancing against how obvious it is that I need to get this back out there ASAP to get it doing its intended job.

So I kept the crude delay, but I changed it to 5 sec if none of the heaters are on, and 60 sec if either machine is heating. I reduced the target from 2.5 C above the dew point to 1.5 C above the dew point, since the old target of 1.0 C wasn't ever getting the temperature there for either machine under conditions like these. Not sure why the behavior is so different hovering around 70 F as opposed to down toward freezing. I seriously underestimated how much and how often the heaters would come into play on days like this. Nothing is actually sweating right now, but conditions are right on the razor edge, and they apparently stay there a significant proportion of the year.

Long term, I need to find that wifi board and rig this up to talk to the outside world. I can log what's going on day by day, and perhaps set it up so that I can adjust parameters like these from remote.

Longer term, I really need to put my big boy pants on and write altogether more sophisticated code. I need to find my other parts and work that out on the unit I'm building to keep my measuring tools from rusting, then port the code over to this unit once I've worked it all out. The problem is I don't really feel like fooling with any of this. I CAN code, but once the initial coolness of being able to accomplish a project like this wore off, it just became tedious work I'd rather avoid. Humbug.

Still, I better get after it. I'm going to reinstall the unit and then start thinking about something a lot more flexible than this simple delay loop. It isn't getting it done in the real world. Not this time of year anyway.

The heaters get up a little above 200 F.

After soaking for a few minutes, every surface of concern was warm enough to stave off condensation with a dew point of 64 F.

As far as I could tell, the heaters were never going to turn off, so I removed six Phillips screws and two zip screws and brought the whole shebang back in here for round three. I obviously need to get a lot more sophisticated to make this work well, which is a fact I'm balancing against how obvious it is that I need to get this back out there ASAP to get it doing its intended job.

So I kept the crude delay, but I changed it to 5 sec if none of the heaters are on, and 60 sec if either machine is heating. I reduced the target from 2.5 C above the dew point to 1.5 C above the dew point, since the old target of 1.0 C wasn't ever getting the temperature there for either machine under conditions like these. Not sure why the behavior is so different hovering around 70 F as opposed to down toward freezing. I seriously underestimated how much and how often the heaters would come into play on days like this. Nothing is actually sweating right now, but conditions are right on the razor edge, and they apparently stay there a significant proportion of the year.

Long term, I need to find that wifi board and rig this up to talk to the outside world. I can log what's going on day by day, and perhaps set it up so that I can adjust parameters like these from remote.

Longer term, I really need to put my big boy pants on and write altogether more sophisticated code. I need to find my other parts and work that out on the unit I'm building to keep my measuring tools from rusting, then port the code over to this unit once I've worked it all out. The problem is I don't really feel like fooling with any of this. I CAN code, but once the initial coolness of being able to accomplish a project like this wore off, it just became tedious work I'd rather avoid. Humbug.

Still, I better get after it. I'm going to reinstall the unit and then start thinking about something a lot more flexible than this simple delay loop. It isn't getting it done in the real world. Not this time of year anyway.