- Joined

- Dec 8, 2014

- Messages

- 84

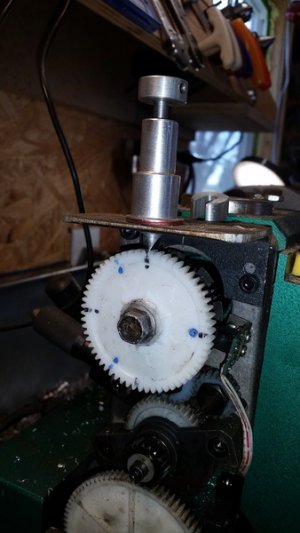

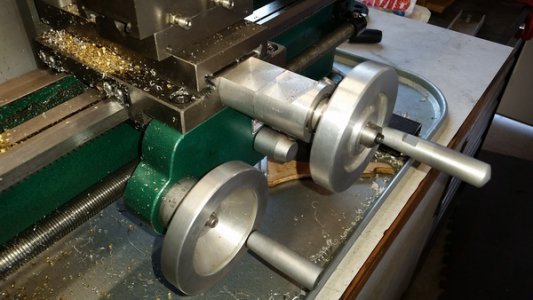

Genius!!! I have been looking for a dedicated index / dividing plate, was actually gonna make one from AI, but your solution is simple and effective. I am assuming that it is a little limited on options for indexing, but none the less a great solution for a tool that would only be used an handful of times. I will be making one of these this weekend.

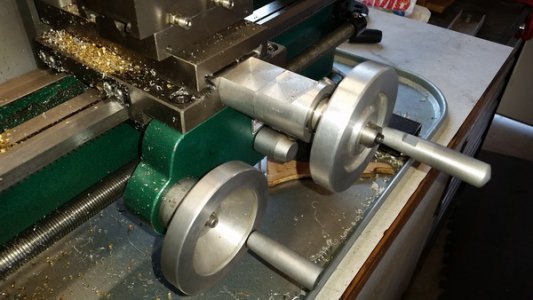

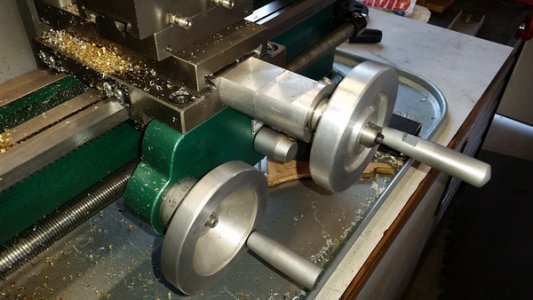

While waiting on the new pulley I broke I bolted it down to some angle. I screwed the plastic end back on to test. Huge difference. Rock solid. Thanks for the info! Vibrations dampened greatly. I'm going to try and do the old indicate and hammer the high spots down before I do the final tighten on the chuck. Last resort I may face the boss off the backplate and cut a new one that is a slight interference fit.No issues at all. i have it bolted to 2 pieces of 1x1 tubing maybe 11 " long. But those aren't bolted to the work table. i got a good deal on a 6" 4 jaw but it might be too big for the lathe.