Ah, there is one more confession to salve my 'newbie machinist's soul'.

Having used too much force to press the spindle into the installed bearing and thus shearing off that 'lip', I'd also managed to get the inner race of the bearing well and truly stuck on to the spindle. When I got the spindle out of the damaged casting, the outer race of the stuck bearing had come off and left just the inner race behind. I could not get my thinnest feeler gauge (0.04mm) between the front of the inner race and the rear of the spindle head.

I did have the new spindle from the new headstock assembly but the keyway at the rear of the spindle shaft didn't match the length of key to hold the drive spindle pulley and the gear that engages with the change gear mechanism. I wasn't confident of my abilities to lengthen the keyway with my equipment (a drill press, a Dremel and a set of files!) such that it would be accurate and not lead to some slop. By the way, I didn't take any photographs of the stuck spindle in-situ as I was pretty depressed at this point (it would have been that two month wait for a new spindle, just like the headstock casting). So anyway, it was a case of trying to rescue the existing spindle.

I tried leaving the spindle in the freezer overnight and then heating the stuck inner race with a propane torch to loosen it but all to no avail.

Then, I tried to chain drill a line of holes in the inner race (front to back) to release it from the spindle. Well, you'll guess how that went, given how hard bearing races are. Even at it's lowest speed (the one I generally use on steel) I couldn't get a decent mark with my centre drills in my drill press.

In the end I decided to grind the inner race to split it just enough and get it to loosen.

This I managed to do:

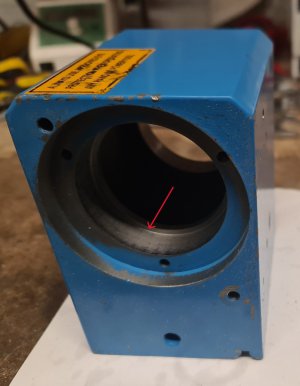

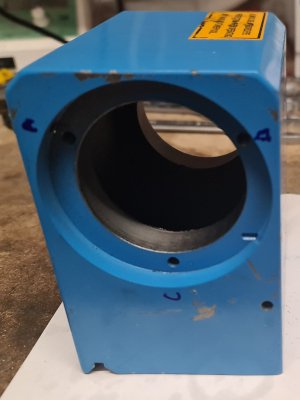

However, I was a little clumsy with my grinding and I did end up taking off some material off the rear of the spindle head as you can see here (this is with the new bearing fitted to the spindle):

It does look worse than it is; I'd say the contact area between the inner race of the new bearing and the rear of the spindle head that I've lost is not much more than 5% and the bearing is held securely in the headstock casting and there's another bearing at the rear anyway so I'm not worried. I've got the headstock back on the bed and firmly fixed down, just to have a sanity check on play and the spindle head feels firmly held when I give it a push and pull, back and forth. I also ran my 0.01mm DTI on the inner bore of the spindle and I'm seeing about 0.01mm of runout (just under really).

If my clumsiness with the grinder causes me any issues, I do still have that spindle with the too-short keyway that is, as yet, unmolested! Without a mill though I'm not convinced I can lengthen the keyway precisely enough to not end up with different issues.

Anyway, thanks for reading so far and any comments are, as always, appreciated (be gentle with me though!

)