That light is perfect! Can you give me some more info on the parts you used and what companies you got them from? Also the wiring is a little confusing on how you hooked it up. You have some great mods!

Thanks Skeeter

Thanks Skeeter!

Sure, no problem. Since you asked about the wiring I'm assuming you have a PM45 so I'll answer in regards to that, if not you'll should still get the general idea I hope.

For the LED ring, I used a 90mm (OD) ring that has 60 SMD (surface mount) LEDs. I purchased mine from ebay seller

three-tech which is JLC Lighting. There are many others on ebay that sell them for varying prices & in different prices, I choose this seller only cause they were closer to me. Search "LED angel eyes" or "LED halo" (they're used for headlight conversions to mimic early 2000s BMW headlights).

Super Bright LEDs also sells them but they did not have the size I needed. It fit right into the hole on my mill's head, no modifications or mounting hardware needed.

The ID of the 90mm ring is just a tad bit too small to fit over the quill bearing cap. I used a Dremel to open up the ID. Didn't take much, a few passes & my ring fit perfectly over the cap.

For the AC-DC converter, I purchased

this one from Amazon. Also can be found on ebay, search "24 VAC to 12 VDC". You can use any 12V DC power source such as a wall wart like

this. It doesn't need to be 1A, I believe my ring runs on just under 300ma. The LED ring has resistors already so you can just hook it up (making sure polarity is correct) to any 12V DC power source & that's it.

The reason I used the AC to DC converter is cause I did not want to power it off an external source like plugging it into an outlet. The stock halogen lamp on the PM45 is 24V AC so I choose to power it off that. That way it's powered off the mill & when I shut off power to the mill the light turns off as well without having to turn of the switch.

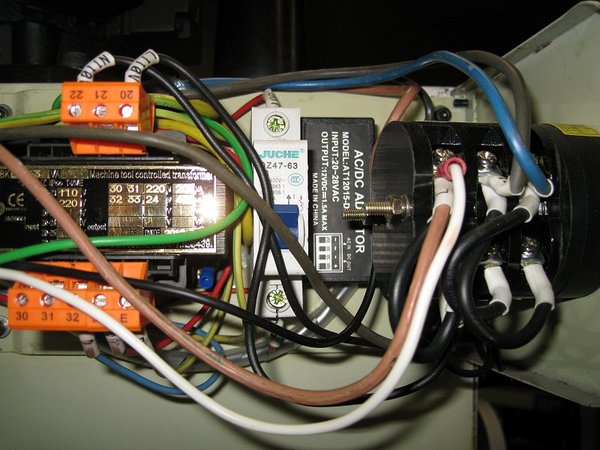

Here's another pic of my control panel. to the left you'll see a transformer with a gold name plate. On it you'll see that terminals 32 & 33 is 24 VAC which again is for the stock lamp. Directly under the transformer is an orange terminal block with terminals 32 & 33 (the blue & red wires) is what you want to wire up the AC to DC converter to. However if you follow the red wire on terminal 33, it leads to the white circuit breaker that's to the right of the transformer. So I hooked up 1 wire from terminal 32 directly to the converter for AC input. Then I hooked up another wire from the output end of the white circuit breaker to the converter for the other AC input.

Then you would run 2 wires for the DC output from the converter to the LED ring and a switch (polarity matters for the LED ring since it's DC). Negative from the converter runs directly to the black wire on the LED ring, do not use the common ground on the machine for negative. Positive from the converter runs to a SPST switch, then another wire from the switch to the red wire on the LED ring. That's all that's needed.

In my case I used a lighted rocker switch that has an LED indicator that runs off 12 VDC so I had to run an additional ground wire to the switch coming of the negative of the converter. This is the

switch that I used, they're local to me but it can also be ordered online & they have other color indicators.

Hope that helps. If you need any more details I'll be happy to answer.