-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Precision Mathews PM1340GT Arrival

- Thread starter zmotorsports

- Start date

-

- Tags

- mike's pm1340gt

- Joined

- Sep 13, 2015

- Messages

- 61

So, my main, and pretty much only major complaint about the PM-1340GT is the stand. We have this awesome, solid, precision lathe, and then we set it on this sort of flimsy stand. I just bump the headstock with my hand, and get vibration/shake in the whole thing. How bad? Maybe not as bad as I think, but all I can think is that I wish this stand was about a 1000 pound cast iron. I'm even considering take it off the stand, taking the two stand pieces out and pouring them full of concrete. I'm also thinking about taking the screw-in leveling pads off and sitting it directly on the floor, and just shimming it to level it. Both of these ideas are not very good.

Any thoughts on how to make this lathe level-able while also giving it the rock-solid stand it deserves?

Also, one question: these leveling pads: is the lock nut intended to go on the bottom, or on the top of the hole? I have them on the bottom of the hole, maybe that's wrong, and causing some of the issue?

Thanks, guys.

RIO

Any thoughts on how to make this lathe level-able while also giving it the rock-solid stand it deserves?

Also, one question: these leveling pads: is the lock nut intended to go on the bottom, or on the top of the hole? I have them on the bottom of the hole, maybe that's wrong, and causing some of the issue?

Thanks, guys.

RIO

My G lathe has a similar stand issue, it just doesn't feel right. I was thinking about building an angle iron frame to wrap each stands base, bolt the stand to it and then put leveling feet in front and in back of the stands for a total of 4 feet instead of 8. In my mind that would make the base deeper and help it be more stable.

Dave

Dave

- Joined

- Dec 26, 2015

- Messages

- 2,079

Dave, first pic is showing where I measured from (hooked on outside of chuck jaw):

Good look at the finished spider, and my Marathon E467 motor:

View attachment 119210

Thanks again, Mike, Mark, et al. I wouldn't have made it this far without you guys.

RIO / Lafe

RIO, Great job. I have a PM1340GT on order - due in probably in March '16. I went out to sanddan's shop yesterday to look over his machine, and take measurements for building my own stand. At the moment, I'm planning to build a torsion-beam stand, bolting the lathe to a 6-foot section of 2 x 10 rectangular steel with 0.25" wall thickness, supported on both ends by welded steel tube frames with space under the lathe for a pair of Lista cabinets. I'll post progress as it goes along - I'm new to welding, so this should be interesting.Good look at the finished spider, and my Marathon E467 motor:

I'd love it if you could post just a few more specifics about your Marathon motor - specifically if it fit, what you had to do to get it mounted to the lathe, the specific motor pulley and belt you ended up using. Thanks for sharing.

David

- Joined

- Jun 12, 2014

- Messages

- 4,811

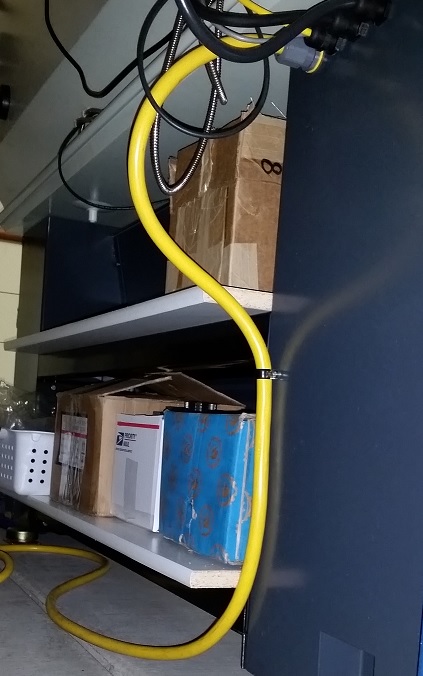

I thought of bracing my lathe cabinets with beams similar to what David is mentioning, and bolt two rectangular beams at the top and bottom on the cabinets on the back. I also sometimes mass load the metal hollow beams by plugging the ends and poring cement in the unbolted section of the beam. But since I have access to the back of my machine, I built two shelves out of 2x2 steel box beams which are bolted between the stands. I mass load them with chucks (just kidding, but a good reason to buy more of them).

Last edited:

- Joined

- Jan 22, 2012

- Messages

- 655

I built a base for my Enco 12x36 lathe so it would have more support than the factory stand. It uses 2 laser cut 1/2" thick plates, one under each column, that are tied together with 2"x3"x.120" wall tubing. This allowed me to spread out the leveling feet for more stability and eliminated the need for the center sheetmetal stiffener. I added a piece of aluminum diamond plate as a shelf. I think I will remove the tubing so I can adapt the plates to the PM1340GT stand width. I'll use 2x2 tubing this time around as the 2x3 was overkill for this (I had some laying around so I used it).

- Joined

- Dec 25, 2015

- Messages

- 214

RIO, Great job. I have a PM1340GT on order - due in probably in March '16. I went out to sanddan's shop yesterday to look over his machine, and take measurements for building my own stand. At the moment, I'm planning to build a torsion-beam stand, bolting the lathe to a 6-foot section of 2 x 10 rectangular steel with 0.25" wall thickness, supported on both ends by welded steel tube frames with space under the lathe for a pair of Lista cabinets. I'll post progress as it goes along - I'm new to welding, so this should be interesting.

David

2x10 1/4" wall square tube? I think you will find that is a little big for the job...way too big and expensive. I just picked up some 2x2" 3/16" for my G4003G, and it is too beefy. I wish I had gone with 1/8" .120 wall.

- Joined

- Mar 22, 2013

- Messages

- 497

Hey Rio, take those screw in leveling pads out if you want it to be more solid. A lot more solid.

They are designed to be bolted to the floor, although most people do not want to do that , (Myself included) it is a LOT more solid.

The stand is fairly heavy steel compared to many, and although it is not a cast iron base, it is pretty solid for a machine of that size.

So before going through all of the trouble of building another stand or adding weight to that one, if you want it to be as solid as possible, anchor it down.

The bolts that came in it originally are meant to adjust the level, and you would anchor it down with the holes just beside those and use both. No shimming needed.

It actually works really well like that, you will be surprised how much of a difference it will make.

They are designed to be bolted to the floor, although most people do not want to do that , (Myself included) it is a LOT more solid.

The stand is fairly heavy steel compared to many, and although it is not a cast iron base, it is pretty solid for a machine of that size.

So before going through all of the trouble of building another stand or adding weight to that one, if you want it to be as solid as possible, anchor it down.

The bolts that came in it originally are meant to adjust the level, and you would anchor it down with the holes just beside those and use both. No shimming needed.

It actually works really well like that, you will be surprised how much of a difference it will make.

- Joined

- Mar 22, 2013

- Messages

- 497

I like the spider that you drilled in there too, looks good!