- Joined

- Feb 21, 2021

- Messages

- 10

Hello!

I am a total beginner when it comes to machining but it is something that I have an inexorable draw towards so I was keeping my eyes open for a cheap middling size lathe. I picked this one up in Canada on my way north to Alaska for 500$ it came with a plastic tote full of tooling and various calipers etc which I haven't yet fully gone through. I've done a little bit of turning on it, made a few components for other projects out of aluminum and plastic, most notably spring loaded nozzle for a pressurized wax injector for lost wax casting. The learning curve has been steep, watching well edited youtube videos of machinist who know their craft made it look easy and I am finding my skills are a far cry from polished. But I certainly have some questions.

First: Does anyone know what kind of lathe this is, I can find no names anywhere on it except for on the forward reverse switch but that is just for the switch. I am hoping if I can find a name it will hone my search for answers, maybe its shop built? The guy I bought it from was selling it for his son who was out in an oil camp. See attached pictures

Second: I am wanting to try my hand at threading and need some help making sense of the attached chart and how to match it to the gears on the lathe.

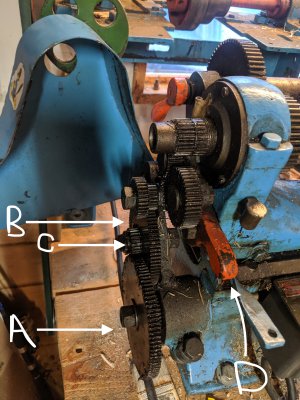

As far as I have been able to figure, the gear marked std is the stud, C & B are the idler and A is the screw (obviously). The spindle is at the top, is there a name for the two gears following (or preceding? Does one start at the screw gear or the spindle when describing the change gear train?) the spindle and before the stud? Im not sure if it is helpful but the gear train that is shown in the pictures is as follows starting at the screw and working towards the stud: Screw: 100 teeth, Small Idler: 24, Lrg Idler: 80, Small std: 16, Lrg std: 24, Unnamed gears: 44, 28, Spindle: 24.

Looking to the chart attached to the gear train cover its shows what I assume to be threads per inch (THD). Stud (STD) Idler (ID) and Screw (SCW). But the idler, and stud have multiple (compound?) gears and the chart only shows one number. How do I read this chart? and seeing as I got this in canada can anyone tell by looking at the numbers if this is for Metric or Imperial? The change gears are stamped with number of teeth not mod whatever which as i understand is the metric convention for gears? I have a small stack of additional gears shown in picture 1, I don't have them in front of me but as I recall the smallest was 45 teeth and the largest was 90 teeth, I will post the exact gears and the dimensions if that is helpful.

Well I know that was a lot of questions all jumbled up but any insight would be helpful and I thank you for your taking the time to read through this.

I am a total beginner when it comes to machining but it is something that I have an inexorable draw towards so I was keeping my eyes open for a cheap middling size lathe. I picked this one up in Canada on my way north to Alaska for 500$ it came with a plastic tote full of tooling and various calipers etc which I haven't yet fully gone through. I've done a little bit of turning on it, made a few components for other projects out of aluminum and plastic, most notably spring loaded nozzle for a pressurized wax injector for lost wax casting. The learning curve has been steep, watching well edited youtube videos of machinist who know their craft made it look easy and I am finding my skills are a far cry from polished. But I certainly have some questions.

First: Does anyone know what kind of lathe this is, I can find no names anywhere on it except for on the forward reverse switch but that is just for the switch. I am hoping if I can find a name it will hone my search for answers, maybe its shop built? The guy I bought it from was selling it for his son who was out in an oil camp. See attached pictures

Second: I am wanting to try my hand at threading and need some help making sense of the attached chart and how to match it to the gears on the lathe.

As far as I have been able to figure, the gear marked std is the stud, C & B are the idler and A is the screw (obviously). The spindle is at the top, is there a name for the two gears following (or preceding? Does one start at the screw gear or the spindle when describing the change gear train?) the spindle and before the stud? Im not sure if it is helpful but the gear train that is shown in the pictures is as follows starting at the screw and working towards the stud: Screw: 100 teeth, Small Idler: 24, Lrg Idler: 80, Small std: 16, Lrg std: 24, Unnamed gears: 44, 28, Spindle: 24.

Looking to the chart attached to the gear train cover its shows what I assume to be threads per inch (THD). Stud (STD) Idler (ID) and Screw (SCW). But the idler, and stud have multiple (compound?) gears and the chart only shows one number. How do I read this chart? and seeing as I got this in canada can anyone tell by looking at the numbers if this is for Metric or Imperial? The change gears are stamped with number of teeth not mod whatever which as i understand is the metric convention for gears? I have a small stack of additional gears shown in picture 1, I don't have them in front of me but as I recall the smallest was 45 teeth and the largest was 90 teeth, I will post the exact gears and the dimensions if that is helpful.

Well I know that was a lot of questions all jumbled up but any insight would be helpful and I thank you for your taking the time to read through this.