-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need advice on a possible purchase of a Sheldon Vernon #0 Mill

- Thread starter CoopVA

- Start date

- Joined

- Sep 28, 2013

- Messages

- 4,308

no, thank you for helping me justify future tooling purchases to the wife  I'm glad they got there ok and hopefully we'll be seeing piles of chips in no time!

I'm glad they got there ok and hopefully we'll be seeing piles of chips in no time!

- Joined

- Feb 1, 2014

- Messages

- 339

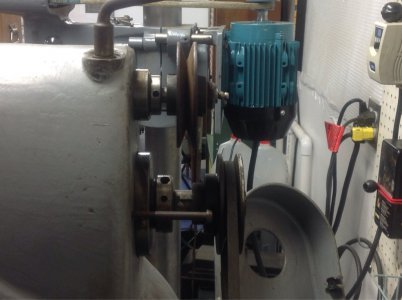

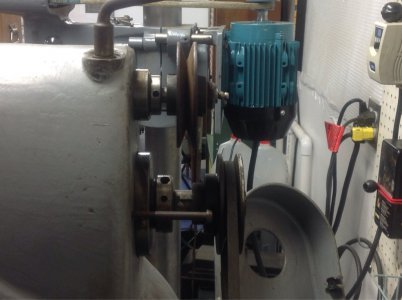

So today I decided to play with the Rusnok vertical head attachment...

It looks like I need to get another pulley to put on the output shaft with a short belt.

Does anyone have one of these set up that can post a picture of the drive side installed? I can find absolutely nothing about this head on the interwebs...

Sent from my iPad using Tapatalk

It looks like I need to get another pulley to put on the output shaft with a short belt.

Does anyone have one of these set up that can post a picture of the drive side installed? I can find absolutely nothing about this head on the interwebs...

Sent from my iPad using Tapatalk

- Joined

- Feb 1, 2014

- Messages

- 339

Finally got the correct belts and was able to do a test fire...

http://youtu.be/9XQH3Mr5IbI

Sent from my iPad using Tapatalk

http://youtu.be/9XQH3Mr5IbI

Sent from my iPad using Tapatalk

- Joined

- Oct 20, 2014

- Messages

- 495

That's excellent! Horizontal or vertical operation really adds flexibility to the mill, and it's hard to beat a sturdy horizontal mill for material removal rate.

Does that vertical head use a ring gear and pinion, or a helical gears running at 90 degrees?

Does that vertical head use a ring gear and pinion, or a helical gears running at 90 degrees?

- Joined

- Feb 1, 2014

- Messages

- 339

That's excellent! Horizontal or vertical operation really adds flexibility to the mill, and it's hard to beat a sturdy horizontal mill for material removal rate.

Does that vertical head use a ring gear and pinion, or a helical gears running at 90 degrees?

Thanks! I'm not sure what the arrangement is. I've been unable to find any in depth information on it at all. I may disassemble it at some point, but not yet...

Sent from my iPad using Tapatalk

Last edited:

- Joined

- Feb 1, 2014

- Messages

- 339

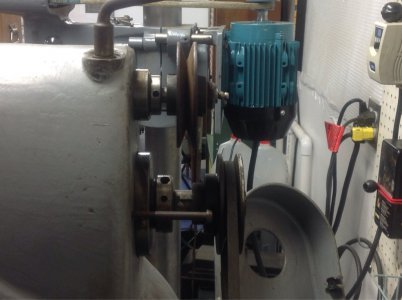

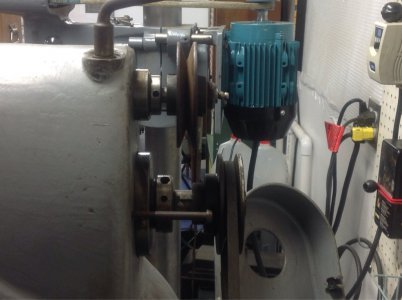

So, come to find out I am an idiot. I did have the back gear engaged. I did not get the direct drive engaged properly. After stewing about it all night, I am out in the shop...

I properly engaged the direct drive and obtained a speed range of about 120 to 560 rpm, which is pretty much exactly what the brochure shows with the low speed motor pulley installed. The high speed pulley would give me 225 to 1100.

With back gear engaged, I get a range of 25 to 120. The high speed pulley would be 40 to 200.

I think I'm good to go!

http://youtu.be/rezTLoukVCQ

Sent from my iPad using Tapatalk

I properly engaged the direct drive and obtained a speed range of about 120 to 560 rpm, which is pretty much exactly what the brochure shows with the low speed motor pulley installed. The high speed pulley would give me 225 to 1100.

With back gear engaged, I get a range of 25 to 120. The high speed pulley would be 40 to 200.

I think I'm good to go!

http://youtu.be/rezTLoukVCQ

Sent from my iPad using Tapatalk

- Joined

- Aug 9, 2011

- Messages

- 67

Great score! I wish mine was as nice and complete.

I picked mine up for $100 though. No table feed assembly or over arm. Just a 3/4" end mill holder and draw bar. It runs well and variable speed works too. Belt has some memory issues so it shook a slight bit. After running it for some time it smoothed out but clearly needs new belts. I picked up a set of B&S #9 collets. Got a job to drill 5/16" hole in the ends of 130 9' long 1x2 tubes with 1/4" plate on the ends. If it wasn't on wheels I probably would of passed on it as I didn't even know if it ran. It has a 25' 10g 4 wire cord and is 3ph. Not much use for it at that time so being able to move it around out of the way was key for this type machine. I do have plans to cut some external splines for some prototype axles using the Ellis Dividing Head I picked up for $250 with full set of plates. Looking for a over arm arbor support for it.

It only has Vernon on the name plate and 3 T-Slots on table.

I picked mine up for $100 though. No table feed assembly or over arm. Just a 3/4" end mill holder and draw bar. It runs well and variable speed works too. Belt has some memory issues so it shook a slight bit. After running it for some time it smoothed out but clearly needs new belts. I picked up a set of B&S #9 collets. Got a job to drill 5/16" hole in the ends of 130 9' long 1x2 tubes with 1/4" plate on the ends. If it wasn't on wheels I probably would of passed on it as I didn't even know if it ran. It has a 25' 10g 4 wire cord and is 3ph. Not much use for it at that time so being able to move it around out of the way was key for this type machine. I do have plans to cut some external splines for some prototype axles using the Ellis Dividing Head I picked up for $250 with full set of plates. Looking for a over arm arbor support for it.

It only has Vernon on the name plate and 3 T-Slots on table.