- Joined

- Jan 9, 2023

- Messages

- 239

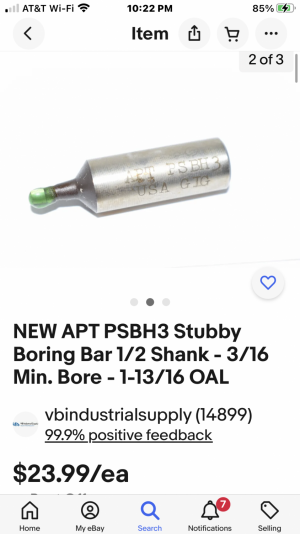

Foud these on ebay but not much else turning up.

NEW Cleveland Super Cobalt Inserts List 859 D-0307 | eBay

Find many great new & used options and get the best deals for NEW Cleveland Super Cobalt Inserts List 859 D-0307 at the best online prices at eBay! Free shipping for many products!

www.ebay.com