- Joined

- Dec 24, 2020

- Messages

- 1,061

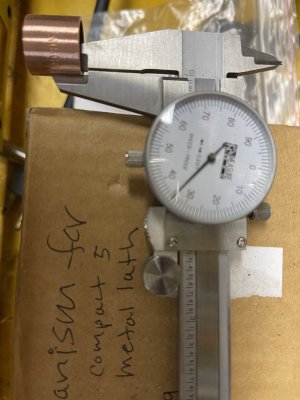

First off, kudos for calling it the correct name (work clamp, not ground clamp)! If the wire is thick enough you don't need the shim, but you can use almost anything as a shim as long as it's conductive....a sliver of copper or brass is fine. I've taken something like a .40S&W case and cut a section of it out to make a shim...worked fine.

Shockingly, Harbor Freight sells this same basic clamp for around $15 and seems to be the equal in quality. I've used them on dozens of welders I've refurbished....really a pretty nice clamp.

Shockingly, Harbor Freight sells this same basic clamp for around $15 and seems to be the equal in quality. I've used them on dozens of welders I've refurbished....really a pretty nice clamp.