- Joined

- Jul 8, 2015

- Messages

- 145

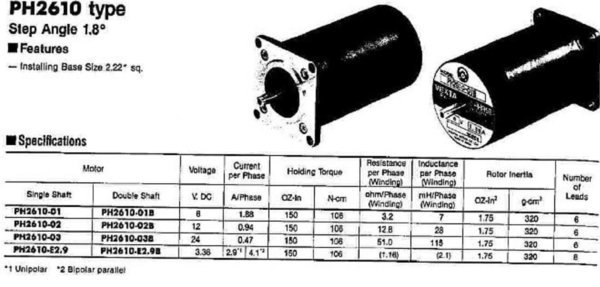

And on to the VEXTA!

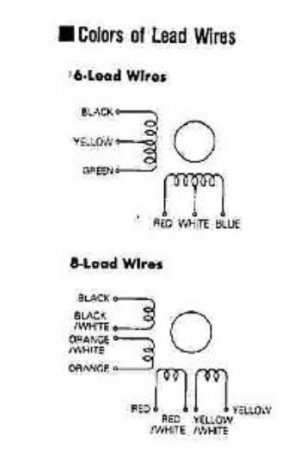

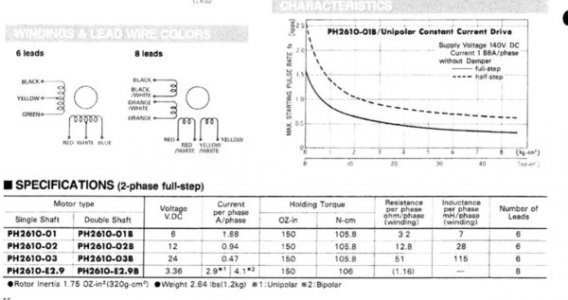

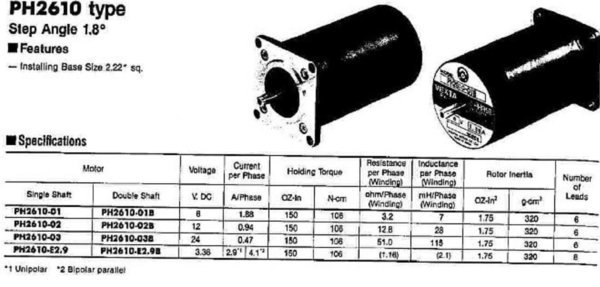

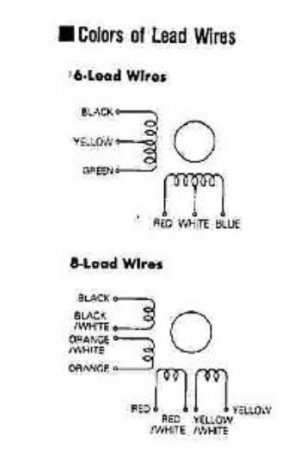

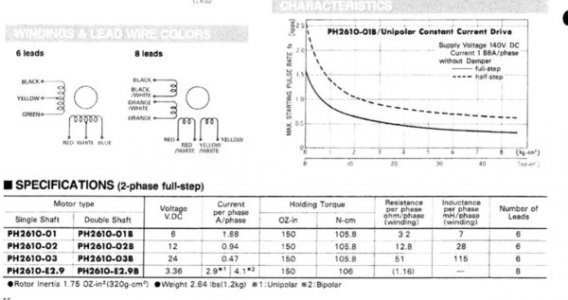

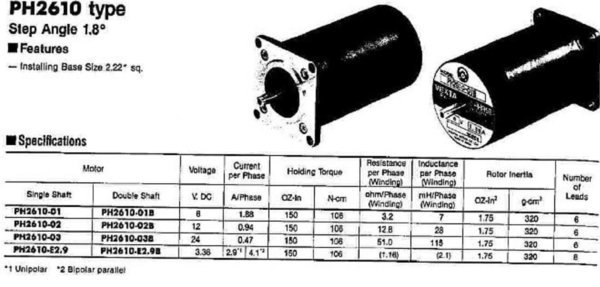

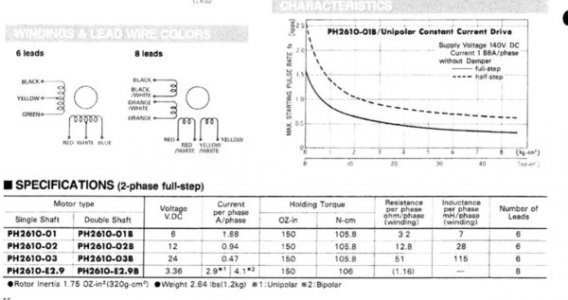

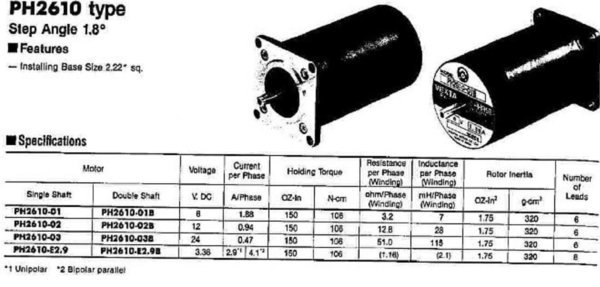

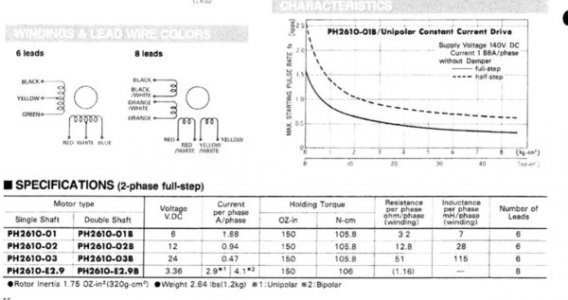

So these are the specs I have found: my steppers are the BOTTOM LINE on the chart below (PH2610-E2.9)

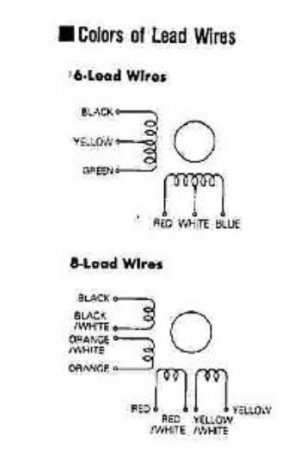

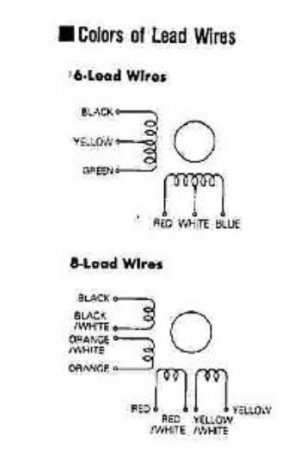

So the big question here is this: WHAT is Unipolar vs BiPolar and whats the Amp/phase difference? (This is the last line on the chart as well)

Is there a benefit to wiring the stepper in BiPolar configuration for my application?

Thanks for reading and hope this Sunday finds you and your families safe, well and in good spirits! Im posting while the kiddo and wife nap before heading out to play!

I appreciate the help and the direction as well!

So these are the specs I have found: my steppers are the BOTTOM LINE on the chart below (PH2610-E2.9)

So the big question here is this: WHAT is Unipolar vs BiPolar and whats the Amp/phase difference? (This is the last line on the chart as well)

Is there a benefit to wiring the stepper in BiPolar configuration for my application?

Thanks for reading and hope this Sunday finds you and your families safe, well and in good spirits! Im posting while the kiddo and wife nap before heading out to play!

I appreciate the help and the direction as well!