- Joined

- Aug 20, 2014

- Messages

- 64

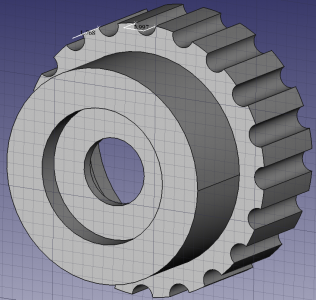

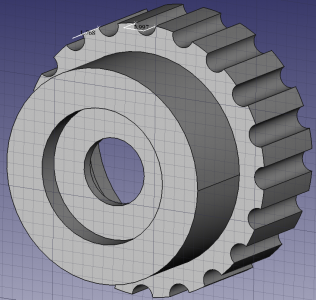

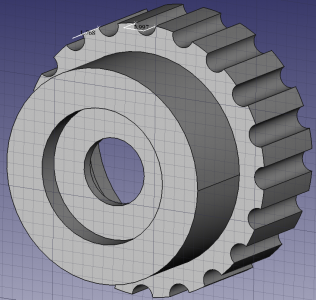

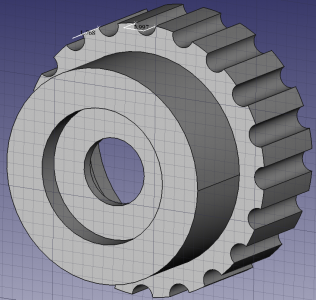

This part is aluminum, only need one for now but will need to make 50 next month otherwise I'd just eyeball the one. Part is about about 0.8" diameter. They have no mechanical function, appearance only. I do not have the funds to buy an indexer. What sort of jig can I make up? If there were 16 slots I'd use a tool socket for reference but there are 20 of them.