Great pictures Mark

About the only way the real activity of the sources you bought could be changed for the worse is if the amount of Am241 in them was reduced. Given the way these things are made, the cost of a "feeble" product would not be significantly different. To get smoke detectors to work, they need enough alpha ionizations to make a current through the air space in the chamber.

For almost all, it is 0.25micrograms, to 0.29 micrograms. The decay events rate in a 0.29 microgram version is 37,000 Bq.

As I understand it, every decay is accompanied by a set of photons, including the 60keV Gamma.

Within the diode material, the photon can miss the atomic cross-section entirely, or it might get to do it's photoelectric effect.

Where we are at odds here is about the 3%. Truly, the height the pulses you see are not altered at all by that. It is the NUMBER of them.

Expect that the probability of a diode response is

0.03 for the 60keV photons. It can be a full height big pulse, but fewer - not so often.

Then that, multiplied by the solid angle fraction of the sphere, which you have as

0.0055. So 0.03 x 0.0055 => 0.000165

This alone brings the count rate to

6.105 per source (of the 60keV type, and also the 1.5keV type, if there were any).

With eight of them, you might get a total of

48 per second.

There will be others, maybe some much bigger, but not from the sources.

The up and then down shape of the absorption probability curve only means that after one has the collection of counts, then one needs to divide by the probability corresponding to the energy of the bucket, to scale the value to properly represent the count that would have happened if the chances of catching all energy photons were equal. In effect, compensation to "level out" the curve.

The calibration to set a pulse height as belonging to a (say) 60keV photon is a post-processing thing. Thankfully, the pulse height vs photon energy relationship is directly proportional, in the linear range of an amplifier.

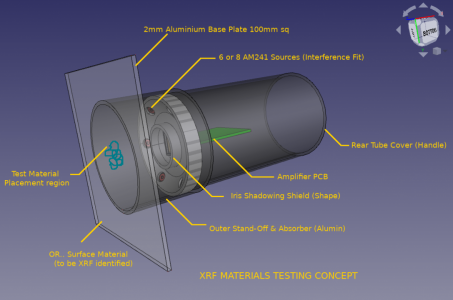

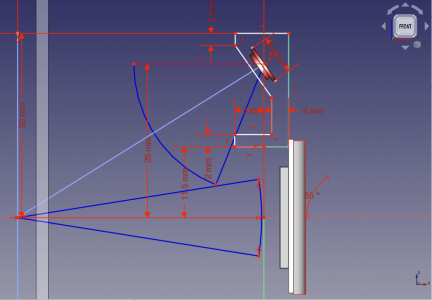

I am thinking your test setup is pretty uncompromising when it comes to excluding unwanted stuff.

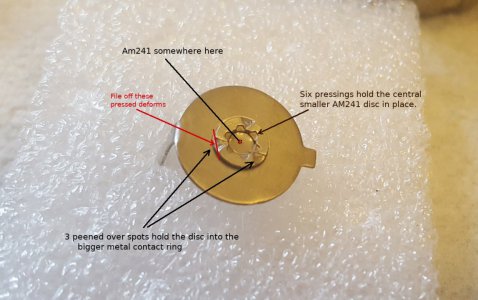

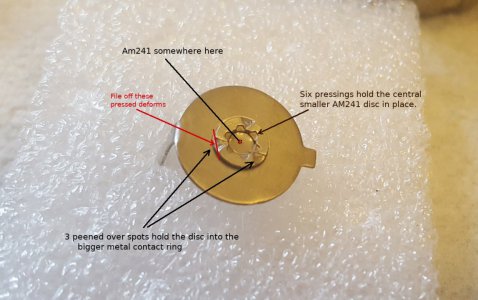

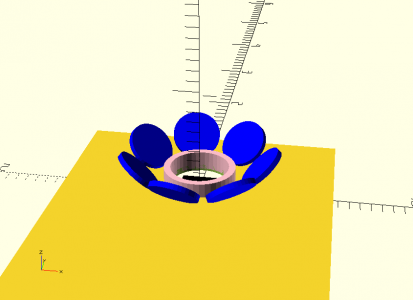

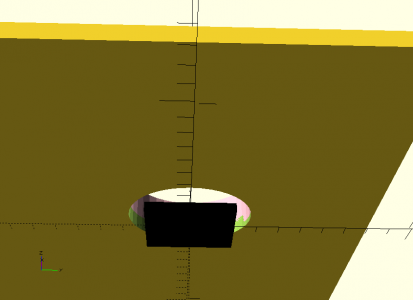

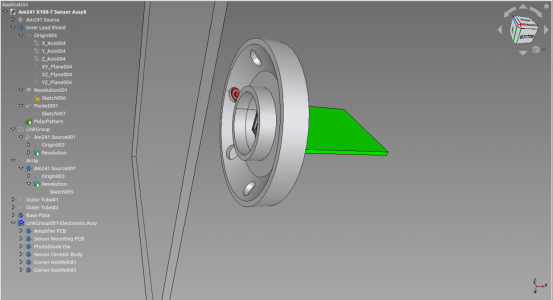

It looks like your sources are still set in the ring of the ion chambers - I think.

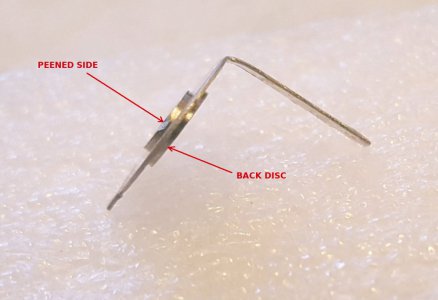

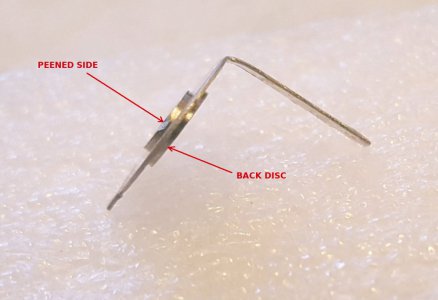

I envisaged a much smaller arrangement, with the source discs removed from all the surrounding mounting and ion chamber connection metal

bits. To get them free, I had to file off the pressed peenings, so I could push them back from the ion chamber connection tag metal.

I had planned to place them in a close crowd, around the diode, but shielded, and unable to irradiate the diode directly.

For a radiation diode test, I think I might have temporarily taped or stuck some directly onto the face of the diode, or put a set of them together on the end of a aluminum test tab wand, all pointing the same way. For any who pick up on this thread late, I include pictures of how I got at the sources.