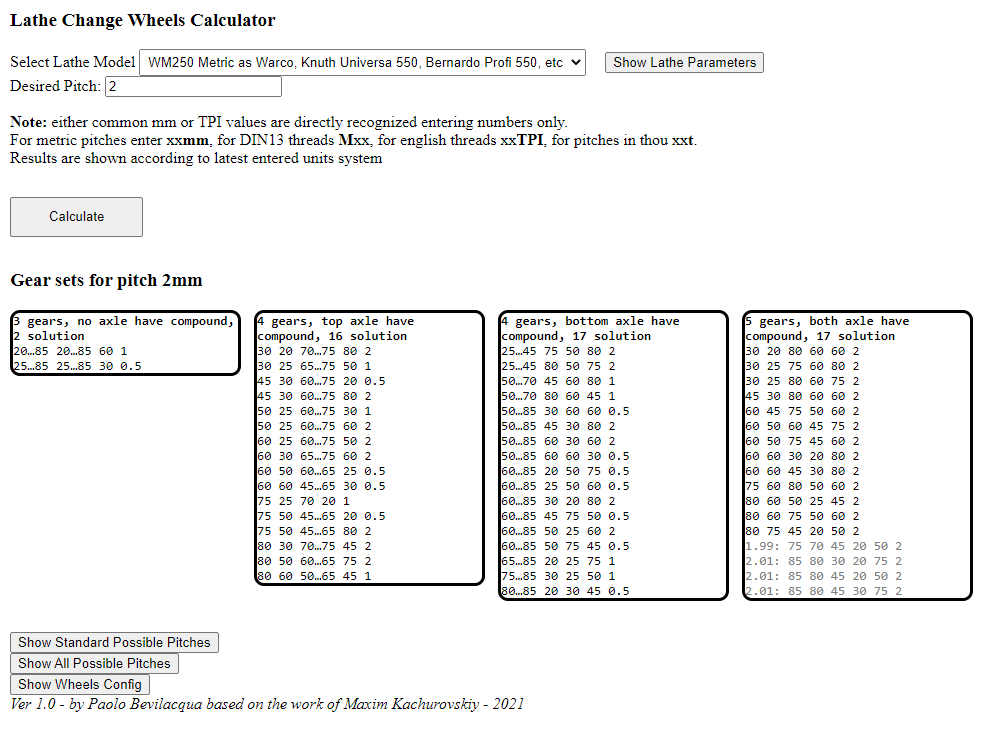

Time ago I needed to cut a non standard thread on my Chinese 250mm lathe, finding the solution was not difficult, but I remained a bit unsatisfied with the available calculators, both online or Windows executables, so I started working on an existing one and made a bunch of improvements to it. Screenshot of the compact version, it has four buttons that can be used to show additional information.

Brief feature list

To avoid cluttering the screen with diagrams, the solutions are compact and given as a single line.

If the solution is exact for a given thread, only the list of gears (and gearbox reduction if any) transmitting motion is given. Gears / cluster physical position is fixed for a same box and is illustrated if you expand "show wheels config".

If the solution is approximate il would be slightly greyed, and show first it actual resulting pitch.

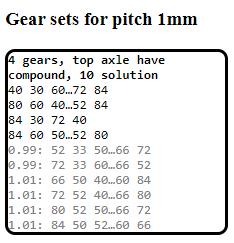

For example in the screenshot above the first 3 gears solution is 20…85 20…85 60 1

The first two gears (on top and bottom axle) are idlers. You can use anything from 20 to 85 teeth - as long these two are matched to fit!

The lowest gears (on the leadscrew, or gearbox input if present) must be 60 teeth.

The gearbox reduction for this solution must be 1. It can be identified with a letter on the lathe itself.

However, 3 gears solution are little used. If we go to use a 4 gears solution there will be no guessing on the idler gear. Of course, 5 gears solution have no idlers.

That's all about the present version, goes without saying it may have bugs and for sure new features can be added. I will try to address both requests as my time permits.

Link to the online version which I'm hosting for the time being: http://pab.fastmail.com/ChangeWheelsCalc/index.html

Remember, as with evertyhing 'JavaScript open source', once opened you can context click on the page, do "view source" and save it locally. It should be identical to the one I'm attaching here.

Questions and issues, please post here, do not PM. That to be more useful to others.

Brief feature list

- Written in JavaScript, runs within the browser on any device. A specific goal is the widest possible compatibility, to run even on old devices.

- It's not dependent on the Internet. Copy it as a single .HTML file on your device then open it with the browser. That will require enabling "local file access" which varies from a device and browser to another.

- Supports metric and English (in TPI or thou) units, including inch leadscrews, with internal conversions reduced to the minimum to preserve accuracy.

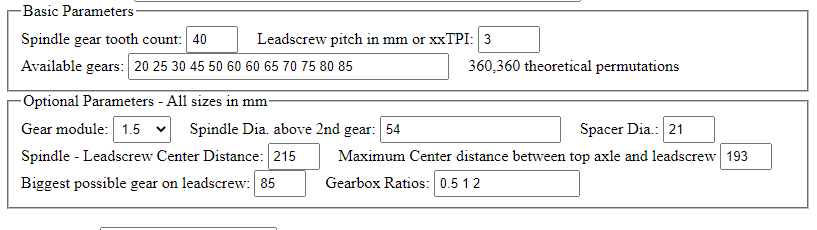

- Has an embedded list of few popular lathe models, new ones can be added editing the source file

- Supports entering or changing lathe parameters in a simple form, so you can test for a different lathe before adding it to the as described above.

- Calculate the most important "physical constrains", to exclude combinations which cannot be fitted for a reason or another

- Supports lathes with one (still untested) or two axles on the quadrant. At this time only a straight quadrant arm pattern is supported.

- Immediately presents the full list of possible threads that can be cut, in either units that you can switch, as well a list of standard ones

- The lists on the point above are presented as links so you can just click on them to get the solutions

- Shows approximate solutions (within 0.01mm, or 4 tenths) also, just because it can

- Includes the gearbox speeds (if any) in the calculation.

- Shows all the setups (as in number of gears used and position of the cluster) which have solutions as separate boxes

- Collapses common solutions using idler gears on a single line. Idlers are represented as a range from the smallest to the largest possible.

To avoid cluttering the screen with diagrams, the solutions are compact and given as a single line.

If the solution is exact for a given thread, only the list of gears (and gearbox reduction if any) transmitting motion is given. Gears / cluster physical position is fixed for a same box and is illustrated if you expand "show wheels config".

If the solution is approximate il would be slightly greyed, and show first it actual resulting pitch.

For example in the screenshot above the first 3 gears solution is 20…85 20…85 60 1

The first two gears (on top and bottom axle) are idlers. You can use anything from 20 to 85 teeth - as long these two are matched to fit!

The lowest gears (on the leadscrew, or gearbox input if present) must be 60 teeth.

The gearbox reduction for this solution must be 1. It can be identified with a letter on the lathe itself.

However, 3 gears solution are little used. If we go to use a 4 gears solution there will be no guessing on the idler gear. Of course, 5 gears solution have no idlers.

That's all about the present version, goes without saying it may have bugs and for sure new features can be added. I will try to address both requests as my time permits.

Link to the online version which I'm hosting for the time being: http://pab.fastmail.com/ChangeWheelsCalc/index.html

Remember, as with evertyhing 'JavaScript open source', once opened you can context click on the page, do "view source" and save it locally. It should be identical to the one I'm attaching here.

Questions and issues, please post here, do not PM. That to be more useful to others.

Attachments

Last edited: