- Joined

- Sep 30, 2017

- Messages

- 38

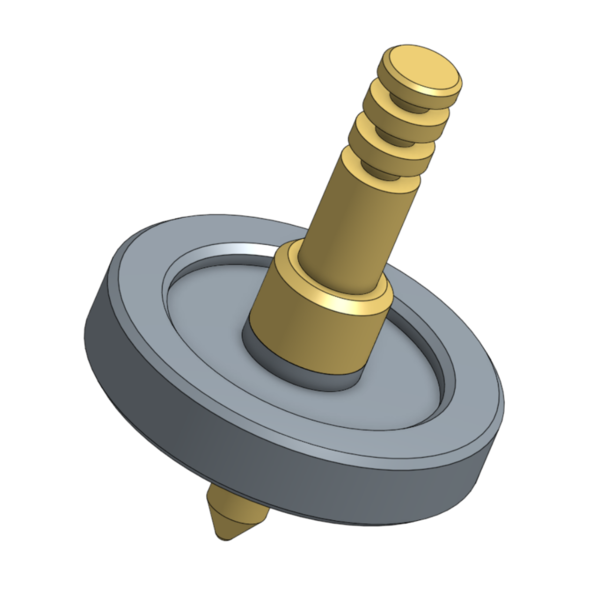

Thanks for the great advice gentlemen! I will do some more measurements soon. I got too restless and had to cut some metal. This was a good little test:

Although I made a few mistakes, the lathe did well. I did have some trouble dealing with the very coarse ratio on the carriage handwheel but hopefully that's something that I'll learn to work with.

Although I made a few mistakes, the lathe did well. I did have some trouble dealing with the very coarse ratio on the carriage handwheel but hopefully that's something that I'll learn to work with.