This is my first post so I hope everyone will bear with me.

So I've been slowly putting my shop back together over the past few years. I say 'back' because I have had many different lathes and mills/shop equipment over the years.

I got the machining bug back when I was just a young buck. After I got married, I slowly started buying machining equipment to satisfy my love to design and fabricate.

To make a VERY long story short, my marriage was always a source of turmoil right from the beginning. My shop became my source of escape and a coping mechanism. (Obviously not the recommended way to make your marriage better!) All I can say is I was young and dumb, plus had no idea what I wanted when it came to relationships. I digress....

Needless to say after 18 years of struggling we called it quits about 5 years ago. What I thought would be an easy transition to the single life was anything but that. I found I no longer had a desire to go out to the shop. I ended up selling my lathe, mill, tig welder, just to name a few.

After some time had passed, and things settled down, my 'hobbies' and interests came back. Phew!!

After kicking myself for getting rid of several pieces of equipment, I saw the silver lining in it all. This time I would 'step up' so to speak.

Well after much research on the web, reading forums and such, I found myself gravitating towards the 1340GT. Of course I would have loved to find a 'mint' monarch 10EE or hardinge HLV! any LaBlond that I could afford, or heck I would have settled on a clean Heavy 10. Everything American I looked at, or considered, was just nothing more than heavy scrap metal. Worse than that is everyone here in Utah thinks they have a treasure, and want top dollar.

Decided new was probably my best option. I'm very well aware of the difference between Taiwan and China machines as a general rule. I was willing to put down more cash for fit and finish. That led me to the 1340GT.

Now I would love to have a 3ooo lb lathe sitting in the garage but decided that wasn't realistic. I had a price point that I wanted to stay under. Realistically I don't turn much that needs that kind of rigidity or dampening, but would have been all over a PM RML if I could have afforded it.

Called Matt at QMT and picked his brain. Also got on several sites, including this one, to accumulate all the info I could get on this lathe. After much thought I pulled the plug. It ended up taking about 2 months to get the lathe, but I knew this going into it so it wasn't a super big deal.

It finally arrived! I took a few days off work to get it all set up. I'm not liking how the crate was so off centered on the pallet. This must have been UPS freight. There was no visible damage though. Opened up the crate and boy did they get a little crazy with the cosmoline! In all fairness I do understand why though. I'd rather have that then rust!

Lets just say it took close to 3 hours to clean it all off.

Based on all the reviews I decided to make some modifications to the stand. I drilled and tapped the 4 corners for 1/2 13 tpi on the head stock end. I had ordered up 6 of the Teco style mounting feet. I also went and ordered up 2 pieces of 3/8 plate to go on the top on the stands under the chip tray. I had considered going with 1/2 inch plate and even putting one long piece across both bases. I finally decided that a 3/8 piece under each of the stands would be sufficient. I wasn't impressed with the original top 'strips' on the stands that the lathe bolted to. The welds definitely didn't have enough heat on them. Same with the ones on the base. Plus as I was drilling and tapping everything, I kept getting small pieces of slag falling off the welds inside the stands. Everything was sticking together fine, but I just felt better about beefing it up. I also went through and chamfered all the existing holes on the stand. Looks like when they punched the holes, they put the convex side up.

I didn't have any plans on bolting the lathe down to the concrete and still don't at this time. Seems stable enough on the additional feet. I can't say whether or not the additional teco mounts made a difference in the stability or not, since I didn't try it with just the 2 on the head stock end.

So far I'm happy with the lathe. It's the 3 phase version, and I'm using a VFD from single phase. I haven't finished the final install as I'm waiting for my ordered electrical enclosure. I do have the VFD temporally hooked up so I can run the lathe. I decided to just use 90% of the original wiring on my install. I'm using the forward and reverse contactors to signal the VFD respectively, I just removed the overload and 3 phase wiring to them.

So basically the controls work just as they would if you were using straight 3 phase power, except that I have a variable speed function. Mounted the POT on the front of the machine in place of the coolant button. And I also swapped the E-Stop out with a nicer AB that I had. The Jog works, but just in the forward position, which is how every lathe I've operated is anyways.

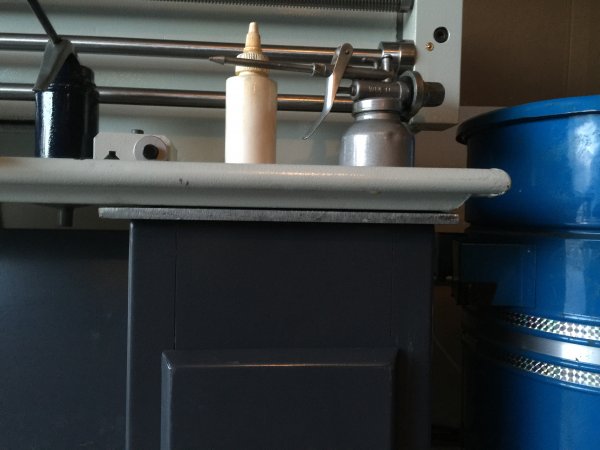

Took out the Starrett 98 and spent some time leveling everything out. I haven't put the test bar in yet to see how close things are. I did mill out my new Aloris BXA base for a nice fit. I have a Dorian at work but actually prefer the Aloris. Both are definitely nice though.

I will post pictures of the process from the pallet to it mounted on the stand. Hopefully they will show up. Ha Ha. I thought I had pictures of the 3/8 plate being drilled and installed, but guess in all the excitement I forgot.

Randy~

So I've been slowly putting my shop back together over the past few years. I say 'back' because I have had many different lathes and mills/shop equipment over the years.

I got the machining bug back when I was just a young buck. After I got married, I slowly started buying machining equipment to satisfy my love to design and fabricate.

To make a VERY long story short, my marriage was always a source of turmoil right from the beginning. My shop became my source of escape and a coping mechanism. (Obviously not the recommended way to make your marriage better!) All I can say is I was young and dumb, plus had no idea what I wanted when it came to relationships. I digress....

Needless to say after 18 years of struggling we called it quits about 5 years ago. What I thought would be an easy transition to the single life was anything but that. I found I no longer had a desire to go out to the shop. I ended up selling my lathe, mill, tig welder, just to name a few.

After some time had passed, and things settled down, my 'hobbies' and interests came back. Phew!!

After kicking myself for getting rid of several pieces of equipment, I saw the silver lining in it all. This time I would 'step up' so to speak.

Well after much research on the web, reading forums and such, I found myself gravitating towards the 1340GT. Of course I would have loved to find a 'mint' monarch 10EE or hardinge HLV! any LaBlond that I could afford, or heck I would have settled on a clean Heavy 10. Everything American I looked at, or considered, was just nothing more than heavy scrap metal. Worse than that is everyone here in Utah thinks they have a treasure, and want top dollar.

Decided new was probably my best option. I'm very well aware of the difference between Taiwan and China machines as a general rule. I was willing to put down more cash for fit and finish. That led me to the 1340GT.

Now I would love to have a 3ooo lb lathe sitting in the garage but decided that wasn't realistic. I had a price point that I wanted to stay under. Realistically I don't turn much that needs that kind of rigidity or dampening, but would have been all over a PM RML if I could have afforded it.

Called Matt at QMT and picked his brain. Also got on several sites, including this one, to accumulate all the info I could get on this lathe. After much thought I pulled the plug. It ended up taking about 2 months to get the lathe, but I knew this going into it so it wasn't a super big deal.

It finally arrived! I took a few days off work to get it all set up. I'm not liking how the crate was so off centered on the pallet. This must have been UPS freight. There was no visible damage though. Opened up the crate and boy did they get a little crazy with the cosmoline! In all fairness I do understand why though. I'd rather have that then rust!

Lets just say it took close to 3 hours to clean it all off.

Based on all the reviews I decided to make some modifications to the stand. I drilled and tapped the 4 corners for 1/2 13 tpi on the head stock end. I had ordered up 6 of the Teco style mounting feet. I also went and ordered up 2 pieces of 3/8 plate to go on the top on the stands under the chip tray. I had considered going with 1/2 inch plate and even putting one long piece across both bases. I finally decided that a 3/8 piece under each of the stands would be sufficient. I wasn't impressed with the original top 'strips' on the stands that the lathe bolted to. The welds definitely didn't have enough heat on them. Same with the ones on the base. Plus as I was drilling and tapping everything, I kept getting small pieces of slag falling off the welds inside the stands. Everything was sticking together fine, but I just felt better about beefing it up. I also went through and chamfered all the existing holes on the stand. Looks like when they punched the holes, they put the convex side up.

I didn't have any plans on bolting the lathe down to the concrete and still don't at this time. Seems stable enough on the additional feet. I can't say whether or not the additional teco mounts made a difference in the stability or not, since I didn't try it with just the 2 on the head stock end.

So far I'm happy with the lathe. It's the 3 phase version, and I'm using a VFD from single phase. I haven't finished the final install as I'm waiting for my ordered electrical enclosure. I do have the VFD temporally hooked up so I can run the lathe. I decided to just use 90% of the original wiring on my install. I'm using the forward and reverse contactors to signal the VFD respectively, I just removed the overload and 3 phase wiring to them.

So basically the controls work just as they would if you were using straight 3 phase power, except that I have a variable speed function. Mounted the POT on the front of the machine in place of the coolant button. And I also swapped the E-Stop out with a nicer AB that I had. The Jog works, but just in the forward position, which is how every lathe I've operated is anyways.

Took out the Starrett 98 and spent some time leveling everything out. I haven't put the test bar in yet to see how close things are. I did mill out my new Aloris BXA base for a nice fit. I have a Dorian at work but actually prefer the Aloris. Both are definitely nice though.

I will post pictures of the process from the pallet to it mounted on the stand. Hopefully they will show up. Ha Ha. I thought I had pictures of the 3/8 plate being drilled and installed, but guess in all the excitement I forgot.

Randy~

Last edited:

I just have one question though. Where is the chips.

I just have one question though. Where is the chips.