-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

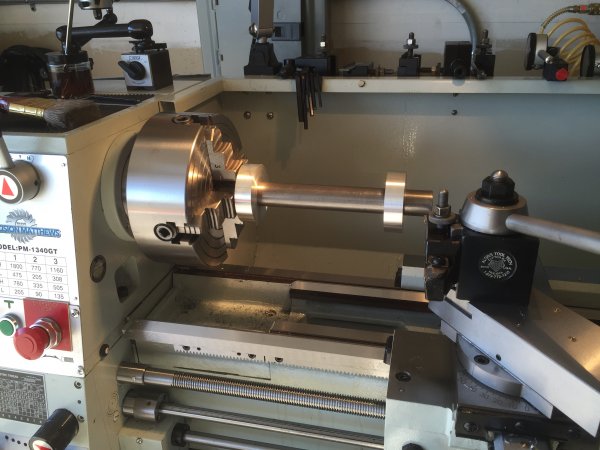

New Pm 1340gt Has Finally Arrived

- Thread starter Randbo

- Start date

Love the Turn-Pro mill. I have a Sharp LMV at work and I prefer the Turn-pro. I would say it's quite accurate, lots of power, and will handle anything I throw at it.How do you like the Turn Pro mill?

I believe it's an exact copy of the ACRA 9X49 (even the paint scheme) and very similar if not identical to the KENT. I would guess they all come out of the same factory. Are you looking at one or just curious?

Randy

Randbo,

Welcome to the site, thanks for all the pictures.

It looks like you are getting very well setup.

I am glad to hear that you are getting back to enjoying your hobbies I think that is an important part of being okay with things.

What projects are on your list?

-brino

Hey Brino,

So many projects on the list right now. I'm thinking about making a power drawbar for the mill. Also wanting to make a welding table similar to a strong arm design. Tail stock die holder, Rotary welding table, finger brake for the hydraulic press, tool post grinder... just to name a few.

- Joined

- Dec 13, 2014

- Messages

- 29

I just built a power drawbar for my mill. I liked a build that I saw on YouTube that Mike(Zmotorsports) did. He sent me his drawings he did and then I converted them to cad to adjust the dimisions to fit my mill. The original design that Mike mirrored was from a guy on YouTube named Colin(Comp Edge X). I also talked to Ray Caniglia from YouTube who also did one and he help me with the pneumatic side of things. I just wanted to make sure I give those guys credit. Anyway it was the best $200 addition for 5 sec. tool changes that I have spent.Hey Brino,

So many projects on the list right now. I'm thinking about making a power drawbar for the mill. Also wanting to make a welding table similar to a strong arm design. Tail stock die holder, Rotary welding table, finger brake for the hydraulic press, tool post grinder... just to name a few.

Last edited:

Awesome work 1cjk!I just built a power drawbar for my mill. I liked a build that I saw on YouTube that Mike(Zmotorsports) did. He sent me his drawings he did and then I converted them to cad to adjust the dimisions to fit my mill. The original design that Mike mirrored was from a guy on YouTube named Colin(Comp Edge X). I also talked to Ray Caniglia from YouTube who also did one and he help me with the pneumatic side of things. I just wanted to make sure I give those guys credit. Anyway it was the best $200 addition for 5 sec. tool changes that I have spent.

View attachment 126501

That was the design I was looking at as well. Watched the YouTube build that both Mike and Colin did. Seemed pretty straight forward. I already have an air cylinder and butterfly impact kicking around that I was going to use. Just have to order up some 6061 and some flow controls.

Would love to see your CAD drawings.

Last edited:

So a little update tonight. I threw together a test bar to check the headstock alignment. Yes it's crude but it's what I had on hand

A little disappointed as it was out nearly 2 and a half thousands over an 8 inch span...Ugh... It was towards the cutting bit. I skimmed it several times just to be sure and yep.

I tried to just tighten the adjustment bolts but couldn't get enough movement. Ended up backing off the 4 bolts on the headstock and proceeded to play "chase my tail" a bit. Finally got it to one tenth and called it good. It's about an 8 inch span between the journals.

One question for those of you who have this lathe. I've noticed when oiling the carriage through the ball oilers, the one closest to the operator takes quite a bit more pressure and you never really "feel" it flowing like the back one does. The ball and seat seem fine, but seems like there is almost a restriction or maybe the passages are smaller. Basically I was curious if everyone else's 1340gt was the same.

A little disappointed as it was out nearly 2 and a half thousands over an 8 inch span...Ugh... It was towards the cutting bit. I skimmed it several times just to be sure and yep.

I tried to just tighten the adjustment bolts but couldn't get enough movement. Ended up backing off the 4 bolts on the headstock and proceeded to play "chase my tail" a bit. Finally got it to one tenth and called it good. It's about an 8 inch span between the journals.

One question for those of you who have this lathe. I've noticed when oiling the carriage through the ball oilers, the one closest to the operator takes quite a bit more pressure and you never really "feel" it flowing like the back one does. The ball and seat seem fine, but seems like there is almost a restriction or maybe the passages are smaller. Basically I was curious if everyone else's 1340gt was the same.

- Joined

- Dec 13, 2014

- Messages

- 29

No problem. I need to clean it up a bit. Give me a few days and I will work on it and send it to you. Pm me your email.Awesome work 1cjk!

That was the design I was looking at as well. Watched the YouTube build that both Mike and Colin did. Seemed pretty straight forward. I already have an air cylinder and butterfly impact kicking around that I was going to use. Just have to order up some 6061 and some flow controls.

Would love to see your CAD drawings.

- Joined

- Jun 12, 2014

- Messages

- 4,812

Very nicely set-up, welcome to the PM1340GT club. Some of the ball oilers do not seem to flow the same, the back carriage ones seem like they have very little resistance, the front ones seem more difficult. I use a brass tip oiler and I have very lightly filed a cross on the tip so the oil can flow a little easier. You will find the machine to be a little stiff on some of the feed/engagement knobs until the machine breaks in, there can also be some over spray between the panel and the knobs. I would also say that the majority of PM1340GT owners have had to align the the headstock with the adjustment screws as you have done. Doesn't take much to get it dialed in, but is you want it to be dead nuts, it is simple and doesn't take long.

- Joined

- Mar 21, 2013

- Messages

- 4,063

What Mark said...

My 1340 wasn't as far out as yours Randbo, but I too had to tweak the spindle/bed alignment. My tailstock was also out by a fair amount. All part of the setup process IMO.

I have a small groove filed into the ends of my goldenrod oilers so that the ball doesn't completely cover the tip and restrict the oil as much.

My 1340 wasn't as far out as yours Randbo, but I too had to tweak the spindle/bed alignment. My tailstock was also out by a fair amount. All part of the setup process IMO.

I have a small groove filed into the ends of my goldenrod oilers so that the ball doesn't completely cover the tip and restrict the oil as much.