so I *****ed on my other thread about the 11 days it took to get to me from PM. 2 days to Orlando and then sat in Estes warehouse for 9 days. I mentioned it to Nicole at PM when I called about something they forgot to ship with the mill and she said that was way too long and not usual. I know it was Estes stalling until they got some other freight going to the small town area I live in about 1 1/2 hours west of Orlando. water under the bridge. other than the delay, the delivery was flawless. no damage to anything and the driver was a nice guy.

they are supposed to contact you the day before with a 4 hour delivery window and then the day of delivery the driver is supposed to call 30 minutes or so before arrival. the night before around 8 pm I received an automated call and it only included the last 2 words so I called the next morning to get the 4 hour window and of course the driver just showed up without calling but so it goes. all good.

the mill and stand were on 2 separate small pallets and not stacked. I backed my pick up to the back of the truck in the pouring rain and he lowered the hydraulic tailgate down on top of mine and rolled them into the bed without incident. I then backed into my shop and unloaded them with my chain hoist. was soaking wet by then so went to the house to change and have a nice lunch.

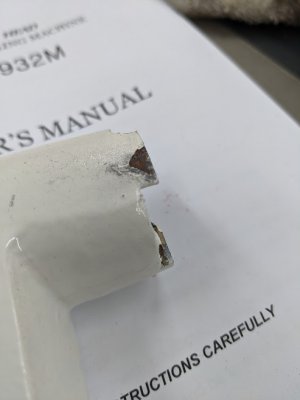

the water damage on the top of the crate is not from today as I threw a tarp over the crates as soon as they were in my truck. happened in china or maybe off loading from the ship or with Estes. the mill was in a big plastic bag inside the crate so no issues.

they are supposed to contact you the day before with a 4 hour delivery window and then the day of delivery the driver is supposed to call 30 minutes or so before arrival. the night before around 8 pm I received an automated call and it only included the last 2 words so I called the next morning to get the 4 hour window and of course the driver just showed up without calling but so it goes. all good.

the mill and stand were on 2 separate small pallets and not stacked. I backed my pick up to the back of the truck in the pouring rain and he lowered the hydraulic tailgate down on top of mine and rolled them into the bed without incident. I then backed into my shop and unloaded them with my chain hoist. was soaking wet by then so went to the house to change and have a nice lunch.

the water damage on the top of the crate is not from today as I threw a tarp over the crates as soon as they were in my truck. happened in china or maybe off loading from the ship or with Estes. the mill was in a big plastic bag inside the crate so no issues.