- Joined

- Jul 9, 2014

- Messages

- 613

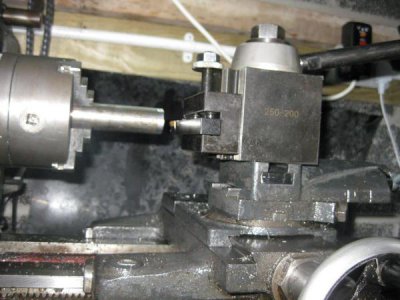

New QCTP a tad too big ..machining it down perhaps

Well the title gives the game away . I've lashed out ,spent the rent & beer money to buy a $200 (ish ) dollar two face QCTP.

I turned the 1/4 " off each side of the anchor bolts retaining flat plate nut down to get the centre mounting bolt arrangement to slide in & out the top slide like a dream . The bolt is way too big for my "Tee " nuts as it totally fills the top of the inverted " channel on the top slide .

On mounting the actual QCTP and putting in a 5/8 shanked tool in a holder I became aware that the piston that locks the tool holder was showing about 1/2 " of piston face above the top edge of the holder when the holder & tool were set for the correct cutting height . The holder is still fully contained on the main QCTP block with about 5/16" of the base of the block showing clear below the cutting tool holder in this current position so I'm not worried that it may be tilted or about to tilt right now .

I ran a test cut ..it works well but I'm a bit concerned that there may be wear /movement developing in the future . Is is a sound idea to turn or have someone mill off the bottom 5/16 of the QCTP block to lower it and thus enable the tool holder to be raised and fully cover the piston face or should I not bother about it ?

When I ordered the QCTP over the phone I gave them distance from a new dead center set in the headstock spindle to the flat of the bed which is 5 & 5/16 " . The suppliers said , " In that case you'll need the mid sized QCTP then" , & that's what they supplied & I paid for .

Well the title gives the game away . I've lashed out ,spent the rent & beer money to buy a $200 (ish ) dollar two face QCTP.

I turned the 1/4 " off each side of the anchor bolts retaining flat plate nut down to get the centre mounting bolt arrangement to slide in & out the top slide like a dream . The bolt is way too big for my "Tee " nuts as it totally fills the top of the inverted " channel on the top slide .

On mounting the actual QCTP and putting in a 5/8 shanked tool in a holder I became aware that the piston that locks the tool holder was showing about 1/2 " of piston face above the top edge of the holder when the holder & tool were set for the correct cutting height . The holder is still fully contained on the main QCTP block with about 5/16" of the base of the block showing clear below the cutting tool holder in this current position so I'm not worried that it may be tilted or about to tilt right now .

I ran a test cut ..it works well but I'm a bit concerned that there may be wear /movement developing in the future . Is is a sound idea to turn or have someone mill off the bottom 5/16 of the QCTP block to lower it and thus enable the tool holder to be raised and fully cover the piston face or should I not bother about it ?

When I ordered the QCTP over the phone I gave them distance from a new dead center set in the headstock spindle to the flat of the bed which is 5 & 5/16 " . The suppliers said , " In that case you'll need the mid sized QCTP then" , & that's what they supplied & I paid for .

Last edited: