- Joined

- Jan 24, 2015

- Messages

- 239

Dear All,

Since late October I have been unable to do any machining. Woe is me. But, the reason is that I began putting in a new shop/garage annex in September. In late October I had to shut down my old shop (the garage) for renovations on that structure, and thus no more machine shop work for me.

Well, the project is done! So, I thought I might show you folks what I did. It's a small shop, but I have big hands.

The first step in this process was creating a space next to my garage for the new building. This was done by a friend of mine's company (Reclaimed Space). This involved digging into the hillside and making things flat. Gravel was then placed in the new flat space, and a limestone wall installed to keep the upper hill slope from moving.

Next was the building. The new building is a 10' x 20' Tough Shed, placed by the guys below about 18" from my garage. I ordered the 16" on center, heavy-duty floor.

The shed was installed in about 6 hours by the above guys. As you can see, I wanted lots of windows. Their is a window on the north side as well.

The Shed installed. You can see the stone wall clearly in this photo.

My brother and I installed the wiring. The blue tape marks where the sliding door goes. The sliding door allows access from the existing garage to the new building. A sliding door was chosen to reduce lost space.

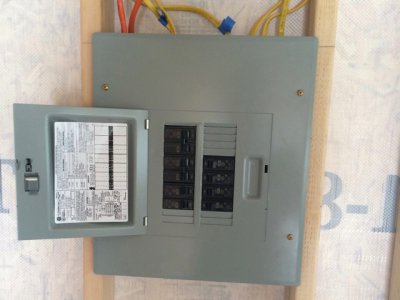

This panel is fed from a sub-panel in the garage that is fed from the main panel at the house. The garage sub-panel is 80 amp, as is the above panel.

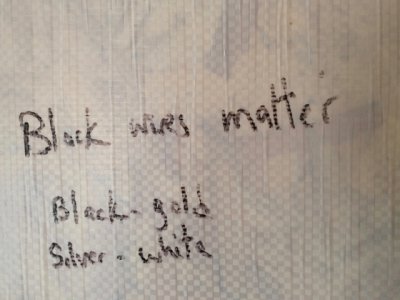

A note my brother made on the wall after I admonished him about how he was hooking up the receptacles.

Almost ready for insulation

The insulation is, obviously, installed. Also installed is the mini-split HVAC system; you can see the indoor component over Alex's shoulder. I put an inside unit in this structure and the garage.

The sheetrock, painting and light installation are done. The color is livable green. The lights are 4' LED shop lights. There are 9 in the building.

After I have somewhat moved in. Just in case folks are wondering, the machining machines are on the benches to the right of the photograph: a Sherline 4400 lathe and a Sherline 5400 mill.

I have much still to move in, and several stands to make. But, I am back doing machining stuff. The rest can wait.

Thank you for reading along.

Cheers and Happy New Year,

Tom

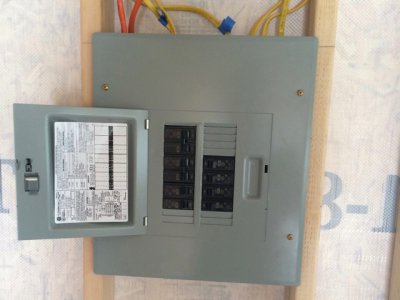

Ignore this photo. I can't figure out how to delete it.

Since late October I have been unable to do any machining. Woe is me. But, the reason is that I began putting in a new shop/garage annex in September. In late October I had to shut down my old shop (the garage) for renovations on that structure, and thus no more machine shop work for me.

Well, the project is done! So, I thought I might show you folks what I did. It's a small shop, but I have big hands.

The first step in this process was creating a space next to my garage for the new building. This was done by a friend of mine's company (Reclaimed Space). This involved digging into the hillside and making things flat. Gravel was then placed in the new flat space, and a limestone wall installed to keep the upper hill slope from moving.

Next was the building. The new building is a 10' x 20' Tough Shed, placed by the guys below about 18" from my garage. I ordered the 16" on center, heavy-duty floor.

The shed was installed in about 6 hours by the above guys. As you can see, I wanted lots of windows. Their is a window on the north side as well.

The Shed installed. You can see the stone wall clearly in this photo.

My brother and I installed the wiring. The blue tape marks where the sliding door goes. The sliding door allows access from the existing garage to the new building. A sliding door was chosen to reduce lost space.

This panel is fed from a sub-panel in the garage that is fed from the main panel at the house. The garage sub-panel is 80 amp, as is the above panel.

A note my brother made on the wall after I admonished him about how he was hooking up the receptacles.

Almost ready for insulation

The insulation is, obviously, installed. Also installed is the mini-split HVAC system; you can see the indoor component over Alex's shoulder. I put an inside unit in this structure and the garage.

The sheetrock, painting and light installation are done. The color is livable green. The lights are 4' LED shop lights. There are 9 in the building.

After I have somewhat moved in. Just in case folks are wondering, the machining machines are on the benches to the right of the photograph: a Sherline 4400 lathe and a Sherline 5400 mill.

I have much still to move in, and several stands to make. But, I am back doing machining stuff. The rest can wait.

Thank you for reading along.

Cheers and Happy New Year,

Tom

Ignore this photo. I can't figure out how to delete it.

Last edited: