Couple of FYI's. The motor may have oil wadding lubrication, double check. If it is, motor oil is no longer to be found, best thing these days, IMHO, is sewing machine oil.

I'd look around for a steady rest and a taper attachment. Let us know if you need pictures.

Others can share their opinions, but the good news is the peg leg is on the platform so the lathe is easily moved. "BUT" the bad news is the lathe isn't bolted down . AND is very much head stock heavy AND not stable side to side AND you have a very narrow platform. Falling over is called a "face-plant" and runied many a lathe. Yes, the pedestal leg is secured by gravity.

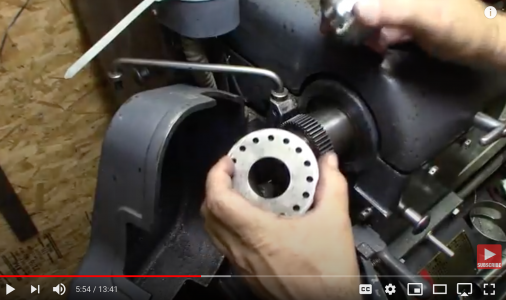

The best thing, IMHO, is to break the lathe down removing the motor & , drive box assembly, remove the bed from the tray/table. If you have access to a cheap Harbor Freight engine hoist, that will work fine to hold it while you remove them. I once made a platform to hold mine up, LOL, can't remember why now. The lift will also work great to hold the lathe while you remove the legs and pan and then you can simply set it in a truck bed or I put mine in a covered cargo trailer to move it. You can also, without any concern but time, remove the headstock and then the parts are easily moved with a cheap Harbor Freight pnumatic tire dolly.

If you elect to try to move it assembled, I suggest you get three good, not Harbor Freight cheap, cargo tie-downs and use two to strap the bed down to the cart, not bending the tray, and the other over the drive box assembly thus also securing the pedestal leg. EDIT: And if at all possible, sling the lathe from the bed, rather than lift it. Then the top heavy isn't an issue.

ASAP, go to the Logan site

Lathe.com run by Scott Logan, grandson of the company founder and just do some reading through the FAQ. If you don't get a manual you can get one from Logan, but drop me an IM and I can give you a couple of suggestions. Not to detract from this really great forum, but Scott moderates a Logan

groups.io forum that's another good source as Scott will weigh in on some questions.He also moderates a FaceBook group that am a member of but don't really follow.

Kerosene is your friend for cleaning, many options for rust removal Evaporust being the easiest, It can costly and container size/shape can be an issue. if you want original paint, the color is in the Logan FAQ.