-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New To Me, Jet 1336pbd - With Some "issues"

- Thread starter Steve Shannon

- Start date

-

- Tags

- jet 1336pbd jet belt drive pbd

- Joined

- Nov 27, 2015

- Messages

- 603

I think I'll pick up some vee blocks and a dial test indicator as well. No more work on this till after January 21st though. In two days I'll be retired; in four I'll have a new position as a babysitter for our first grandchild!

Steve Shannon, P.E.

Steve Shannon, P.E.

- Joined

- Jan 2, 2014

- Messages

- 8,852

Those are always useful tools; in fact I consider both necessities for the shop.I think I'll pick up some vee blocks and a dial test indicator as well.

Cool congratulations!In two days I'll be retired

Even cooler. Not only are you helping out your kids, but you will build a bond with your grandchild that you would never have had otherwise.in four I'll have a new position as a babysitter for our first grandchild!

Enjoy his/her first Christmas!

-brino

- Joined

- Nov 27, 2015

- Messages

- 603

Thanks!

Steve Shannon, P.E.

Steve Shannon, P.E.

I think I'll pick up some vee blocks and a dial test indicator as well. No more work on this till after January 21st though. In two days I'll be retired; in four I'll have a new position as a babysitter for our first grandchild!

Steve Shannon, P.E.

Congrats on your retirement. Did it four years ago and look forward to every day. We have our four grand daughters visiting this weekend. It's a mad house but enjoying every minute. You will come to a point where you look forward to the chaos.

Tom S.

- Joined

- Nov 27, 2015

- Messages

- 603

She's four months old this month. Is it too early to give her a Sherline?

Edit: I checked prices for Sherline; maybe she and I will rebuild a South Bend lathe someday. I just have to convince her dad and mom to set aside space for a workshop.

Steve Shannon, P.E.

Edit: I checked prices for Sherline; maybe she and I will rebuild a South Bend lathe someday. I just have to convince her dad and mom to set aside space for a workshop.

Steve Shannon, P.E.

Last edited:

- Joined

- Nov 27, 2015

- Messages

- 603

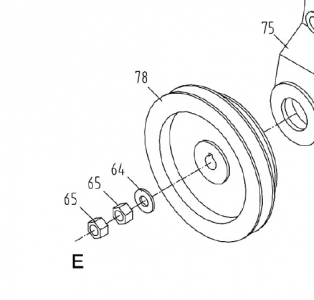

I'm back. Today I removed the countershaft from the headstock. That's necessary to replace the pulley on the end:

Once I got that pulley off I discovered that the keyway on the shaft was damaged also. Here's a picture of it:

My next goal is to remove the spindle. Unfortunately I'm a bit stumped. I know it has to come out toward the bed, but the bearing cover is held not only by four cap screws but by the spindle itself, so somehow I need to clear the OD of the bearing cap. I don't have a bearing puller that will do that. Here's that picture:

More next week. I'm just getting used to retirement.

Sent from my iPhone using Tapatalk

Once I got that pulley off I discovered that the keyway on the shaft was damaged also. Here's a picture of it:

My next goal is to remove the spindle. Unfortunately I'm a bit stumped. I know it has to come out toward the bed, but the bearing cover is held not only by four cap screws but by the spindle itself, so somehow I need to clear the OD of the bearing cap. I don't have a bearing puller that will do that. Here's that picture:

More next week. I'm just getting used to retirement.

Sent from my iPhone using Tapatalk

- Joined

- Nov 27, 2015

- Messages

- 603

I found the tapered roller bearings for the spindle on Amazon today. From JetTools.com they would have been $100 each. From Amazon they are $39 and $57 plus shipping. I'll give the local bearing supply house first crack at it, but I wanted to make sure they were available. They don't even seem to be anything "special": HR30211J and HR30212J.

Also, I think I figured out how to pull the spindle. I always figured I would just put a piece of protected all-thread through the spindle with a large washer and nut on the outboard end and some way of clearing the bearing cap on the spindle nose end. I bet I can find a PVC coupling (or short piece of well pipe) that just clears the cap. I'll post a picture once I get it rigged up, but I won't be able to play with it until Friday.

Also, I think I figured out how to pull the spindle. I always figured I would just put a piece of protected all-thread through the spindle with a large washer and nut on the outboard end and some way of clearing the bearing cap on the spindle nose end. I bet I can find a PVC coupling (or short piece of well pipe) that just clears the cap. I'll post a picture once I get it rigged up, but I won't be able to play with it until Friday.

Last edited:

- Joined

- Nov 27, 2015

- Messages

- 603

It appears that the pulley that I removed was not the original. The bore seemed larger than the original pulley and the key seemed smaller than the slot in the pulley. Either that or when the damage to the key slot happened it reamed out some metal to the bore as well. This pulley had two set screws, which each was locked in place by an additional set screw. I think I've seen that some of you call that extra a grub screw. Is that correct?

Anyway, as designed, the pulley is actually held against rotation by the key and it's held on the shaft by a nut and lock nut at the end of the shaft:

Anyway, as designed, the pulley is actually held against rotation by the key and it's held on the shaft by a nut and lock nut at the end of the shaft:

- Joined

- Oct 6, 2010

- Messages

- 699

I found the tapered roller bearings for the spindle on Amazon today. From JetTools.com they would have been $100 each. From Amazon they are $39 and $57 plus shipping. I'll give the local bearing supply house first crack at it, but I wanted to make sure they were available. They don't even seem to be anything "special": HR30211J and HR30212J.

Also, I think I figured out how to pull the spindle. I always figured I would just put a piece of protected all-thread through the spindle with a large washer and nut on the outboard end and some way of clearing the bearing cap on the spindle nose end. I bet I can find a PVC coupling (or short piece of well pipe) that just clears the cap. I'll post a picture once I get it rigged up, but I won't be able to play with it until Friday.

I have been following your thread with interest as I too have adopted a older Jet lathe (actually 2 lathes) with issues.

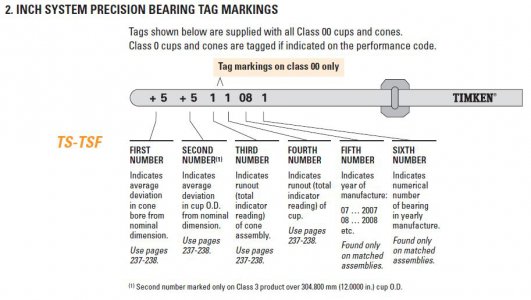

You probably already know this but it might be helpful for some of our fellow Hobby Machinist to learn a little about bearing precision.

All bearings that will fit into our machines are not equal. Some are more accurate than others. The bearing manufacturers produce the bearings as best they can and then select and grade them. This quality and grading process adds cost. The end user (machine manufacturers or hobbyist) specify what quality bearing they need, want, or willing to pay for. In today’s world the good manufacturers like the one I have selected (Timken) to post a link to make really good accurate products. We have no idea what quality bearing was originally supplied from the original manufacturer of our hobby machines, what is supplied by Jet Tools, or the others you contacted for prices. I would hope that Jet Tools would supply the appropriate quality level for their application but who knows in today’s global market place.

For the learning pleasure of our members I have attached to link below that will supply a little information about bearing precision:

http://www.timken.com/en-US/products/Documents/Super-Precision-Bearings-for-Machine-Tool-Applications-Catalog.pdf

The picture below shows how this bearing manufacturer “may” label their precision products.

The picture gives some other page numbers for the TIR readings for those interested. The web link above also includes links to other publications about installing and service this type of bears.

Good luck with your project.

Benny

The Orphanage Never Closes