- Joined

- Jul 27, 2021

- Messages

- 221

Greetings,

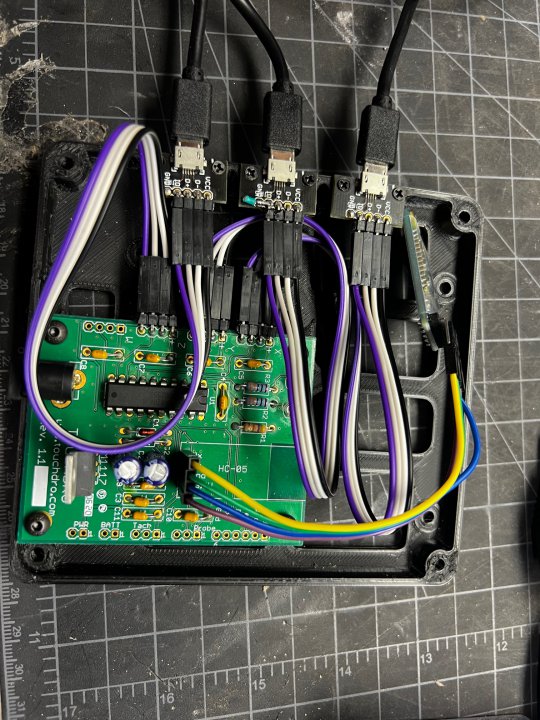

I recently completed what I am sure will be V1 of my TouchDRO install on my HF 33686 column mill/drill. I am new to all of this so comments or critiques are welcome.

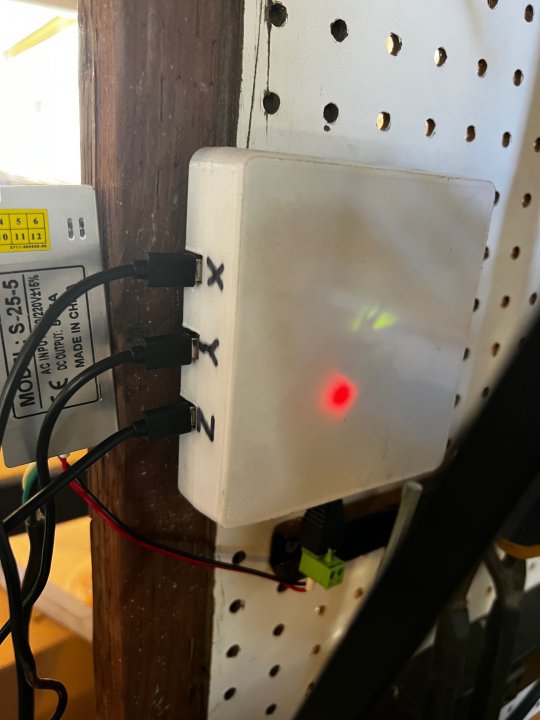

I bought the DIY kit from Yuriy which is excellent. That soldered together nicely and other than a few stumbles on my part getting the USB wires connected right it has worked well. I downloaded an enclosure off Thingiverse for my 3D printer but had to modify it a bit to get the standoff holes in the right places. I liked it because it has a thin cover that when printed in white lets me see the "heartbeat" and bluetooth LEDs blinking.

This was mounted on a vertical surface just behind the mill and uses a little 5V power supply from Amazon that (hopefully) will prevent any interference from the motor on the machine. I still need to print a chip cover for that power supply.

I recently completed what I am sure will be V1 of my TouchDRO install on my HF 33686 column mill/drill. I am new to all of this so comments or critiques are welcome.

I bought the DIY kit from Yuriy which is excellent. That soldered together nicely and other than a few stumbles on my part getting the USB wires connected right it has worked well. I downloaded an enclosure off Thingiverse for my 3D printer but had to modify it a bit to get the standoff holes in the right places. I liked it because it has a thin cover that when printed in white lets me see the "heartbeat" and bluetooth LEDs blinking.

This was mounted on a vertical surface just behind the mill and uses a little 5V power supply from Amazon that (hopefully) will prevent any interference from the motor on the machine. I still need to print a chip cover for that power supply.