Specifications of the Taig Micro Lathe II

|

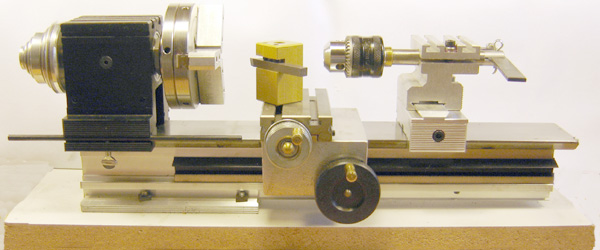

| The Assembled Taig Lathe with 1150 tailstock, 1050 3 jaw chuck, 1097D tool bit, 1023 mounting board, 1162 pulley set and 1092 drill chuck |

| Swing over bed | 4.5" |

| Swing over crosslide | 2.375" |

| Overall length of bed | 15.5" |

| Overall length of lathe | 16.5"* |

| Bed Construction | Ground Steel Dovetailed Ways on Concrete Filled Aluminum Extrusion |

| Bed Mounting | Cantilevered Instument Lathe Style |

| Bed Width | 2-5/16" |

| Headstock Normality to Bed | .0004" max. error |

| Cross slide Normality to Bed | .0004" max. error |

| Max. taper bed dovetail | .0001" |

| Dovetail Angles | 45 deg. All Slides |

| Gib Type | Bronze (Brass?) 3 setscrew Horizontal adjustment, 2 Vertical Locking Screws |

| Tool bit size | .25" |

| Distance between centres | 9.75" |

| Carriage Travel** | 9", .60" per handwheel revolution |

| Carriage Material | Aluminum Casting |

| Crosslide Travel | 2.25", .050" per handle revolution |

| Crosslide Dial Divisions | .050" in .001" steps (50 divisions) |

| Bearing Size OD | 1.5748" (40mm) |

| ID | .6692" (17mm) |

| Max Bearing Runout | .0004 |

| Spindle Nose thread | 3/4"-16 SAE |

| Spindle Nose register | .75" dia., .10" length |

| Spindle Hole | .343" |

| Spindle Taper | 15 deg. included |

| Collet Type | 15 deg. self releasing, threaded spindle nose closer*** |

| Max Collet ID | 5/16"**** |

| Headstock Pulley Bore | 5/8" |

| Standard Speed rpm | 525-5300, six steps, Max. 7000 rpm. (525,825,1300,2100,3350,5300) |

| Tailstock Chuck Integral Mount | 3/8"-24 tpi. |

| Tailstock spindle travel | 1.2" |

| T-slot locations | Crosslide(2), back side of Headstock and Tailstock (1),Top of Headstock(2), Front side of Headstock(1), Top of Tailstock(2),Compound & Milling Slide(2) |

| T-slot Nut | Standard 10-32 Square Nut |

*This doesn't include the space taken up by a motor

**This is deceptive, with the 4 jaw chuck on, the actual travel between the fully extended tailstock centre and the 4 jaw chuck jaws, without moving the toolpost on the slide (which allows you to take several cuts at different points on the work) is 5.875"

***Thus work can be fed through the spindle, unlike a drawbar closing mechanism.

****5/16" collet is not bored through, 9/32" collet is the largest that can have stock fed through.

This was my first lathe. My favorite tool. Really! Check out

https://www.cartertools.com/ Nick Carter is the best. I bought mine from him 13 years ago and he will still answer a question just like I was a new customer. You may ultimately get a larger machine but you will keep the Taig!