- Joined

- Oct 7, 2020

- Messages

- 2,115

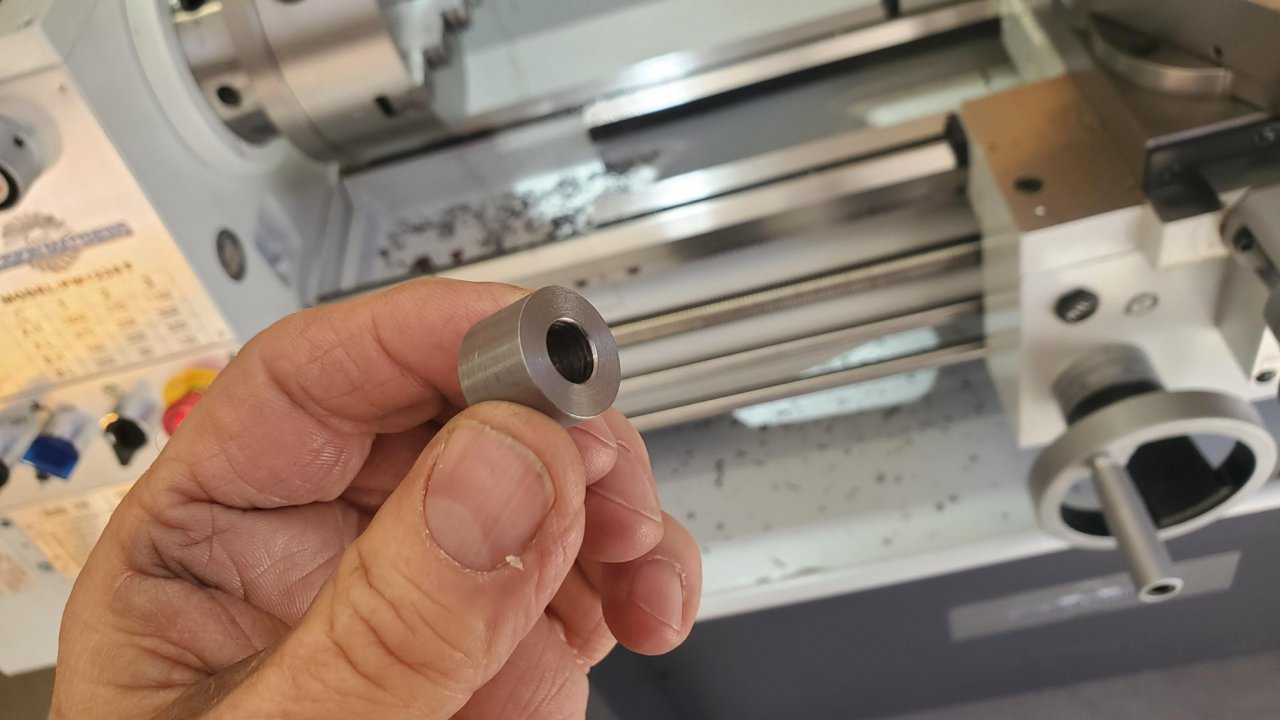

I have the lathe all set up and working, I tried my best to get it leveled, It's pretty close. I'll work on it some more later. It took longer than I thought to get all electrics working. Thanks to Mark @mksj for all of the assistance with the VFD and lathe wiring. I still need to install the DRO but that will have to wait for a bit. I did fire it up and made a few chips, nothing fancy. I made a little spacer and other than that just turned down some down a shaft some. My greenness really shines. Sense I have never operated a lathe before it has been a real learning experience. I bought the master turning kit from PM when I ordered the lathe, of course no identification of what cutter does what. LOL

I did get the mill off the pallet today and started reading through the manual and looking at all the controls. At the same time putting a plan together to get it across the shop and into its more permanent location. That sucker is heavy!

Anyway, here are a couple of the photos of the lathe just to show that it really did happen!

I did get the mill off the pallet today and started reading through the manual and looking at all the controls. At the same time putting a plan together to get it across the shop and into its more permanent location. That sucker is heavy!

Anyway, here are a couple of the photos of the lathe just to show that it really did happen!