- Joined

- Aug 29, 2016

- Messages

- 121

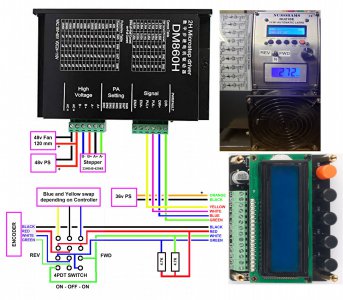

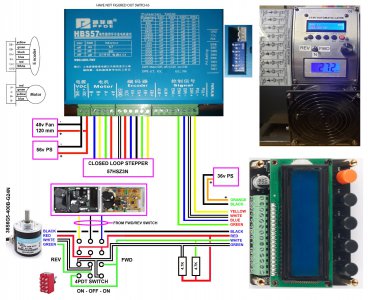

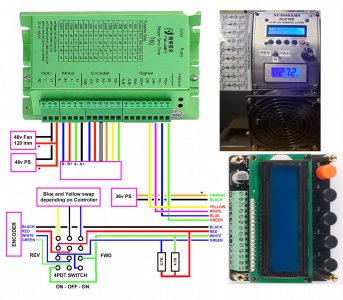

When my Numobams controller died very early I ordered a similar controller from Aliexpress. That controller worked well in forward. But when the chuck went into reverse any function that relied on the optical encoder ( chuck rotation) got lost because it could not deal with the encoder running backwards. It took awhile but I solved the problem by putting in a 4PDT switch to reverse the encoder outputs and fake the controller into thinking the lathe chuck was rotating forward. It turned out that unless I added 4.7K pullups to the A and B inputs the encoder got destroyed by the controller when flipping the forward/reverse switch ( do not know the mechanism that kills the encoder). I lost 2 encoders finding this out. I contacted the manufacturer through the sales company and they refuse to even look at the problem so I do not see it being solved. I was told that Numobams and the similar controller are both made by the same manufacturer so I expect the same problems with Numobams.

I have posted the schematic showing how to dummy the encoder to get forward and reverse working on all functions. The only thing not perfect is that in reverse LEFT and RIGHT threads are reversed.

I eventually changed out the power supply to 48v, a compatible stepper driver, .and put a large 120 mm fan on the stepper to allow overdriving the current. It was needed because the stepper can lose steps if the cutter has too much resistance.

The bottom line is that I would not purchase this controller unless you feel comfortable replacing power supplies and rewiring/replacing switches. I also modified the Numobams plate to accept the original tachometer. and moved the FWD/REV switch to the plate.

In it's current state after weeks of work and extra cost I have decent operation.

The manufacturer just got back and stated that they only work with the chuck in the forward rotation for any function depending on chuck rotation.

I have posted the schematic showing how to dummy the encoder to get forward and reverse working on all functions. The only thing not perfect is that in reverse LEFT and RIGHT threads are reversed.

I eventually changed out the power supply to 48v, a compatible stepper driver, .and put a large 120 mm fan on the stepper to allow overdriving the current. It was needed because the stepper can lose steps if the cutter has too much resistance.

The bottom line is that I would not purchase this controller unless you feel comfortable replacing power supplies and rewiring/replacing switches. I also modified the Numobams plate to accept the original tachometer. and moved the FWD/REV switch to the plate.

In it's current state after weeks of work and extra cost I have decent operation.

The manufacturer just got back and stated that they only work with the chuck in the forward rotation for any function depending on chuck rotation.

Attachments

Last edited: