- Joined

- Aug 16, 2017

- Messages

- 150

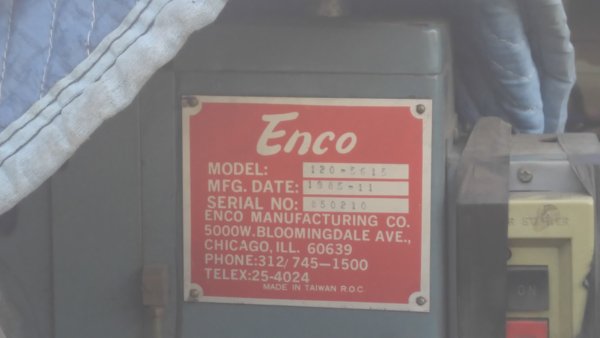

While trolling around the interwebs, I stumbled on a listing for an Enco 6 x 12 surface grinder. They were asking $350 so I sent a message. It was still available and I went to look at it. I was expecting a 240V 3ph machine, but it was a 115V 1ph. I heard it run and I offered $300, he said yes. Lousy timing with the space issues in my garage, but a deal doesn't wait.

Mark

Mark