-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ok, don't laugh...

- Thread starter TerryH

- Start date

- Joined

- May 8, 2018

- Messages

- 336

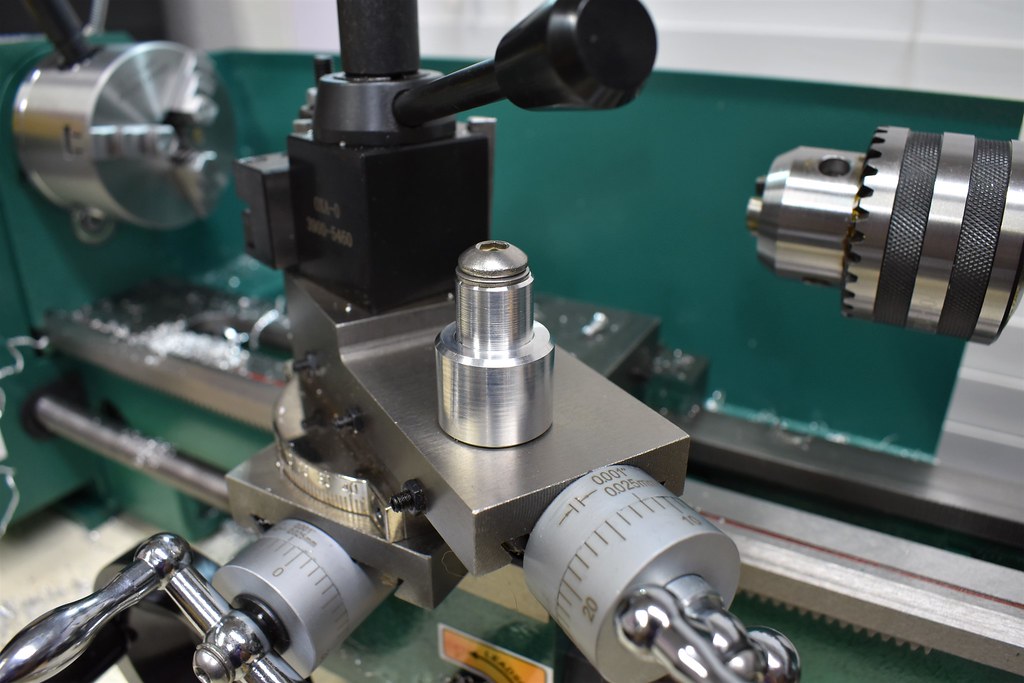

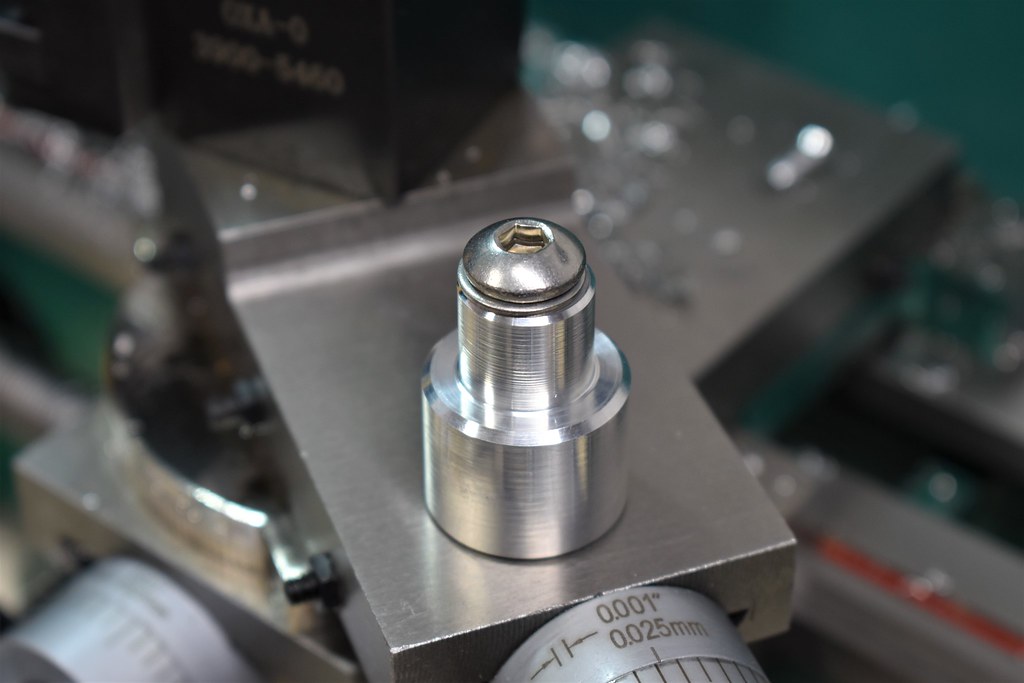

Cool, looks good. What is it?

Thanks. Just an exercise in machining. No purpose just trying some different operations for the first time to see if I could actually do it.

- Joined

- Nov 27, 2012

- Messages

- 7,854

Thanks. Just an exercise in machining. No purpose just trying some different operations for the first time to see if I could actually do it.

Looks good to me, great job! Of course it has a purpose. It's a mini screw jack!

- Joined

- Apr 30, 2015

- Messages

- 11,294

It's early yet- there will be plenty of opportunities to break things for fun and profit! LOL

Mark

Mark

- Joined

- Dec 20, 2012

- Messages

- 9,422

Thanks. Just an exercise in machining. No purpose just trying some different operations for the first time to see if I could actually do it.

Hey, you faced it, turned to a shoulder, chamfered the edges cleanly, center drilled and tapped it accurately enough to accept a standard screw so basically you performed all four of the basic lathe operations in this one piece - what's to laugh at? You done good, Terry!

- Joined

- May 8, 2018

- Messages

- 336

Nice work!

Thanks!

- Joined

- May 8, 2018

- Messages

- 336

Looks good to me, great job! Of course it has a purpose. It's a mini screw jack!

Thanks! I suppose it is a mini screw jack. Happy accident.