Alright, I have found many used lathes and taken notes on them, spoken with the sellers about it.

I will start with the lowest price one first, which I think seems to be a good deal, wonder what everyone's thoughts are on it, if its a safe buy. I also don't mind rebuilding/scraping it so long not too expensive.

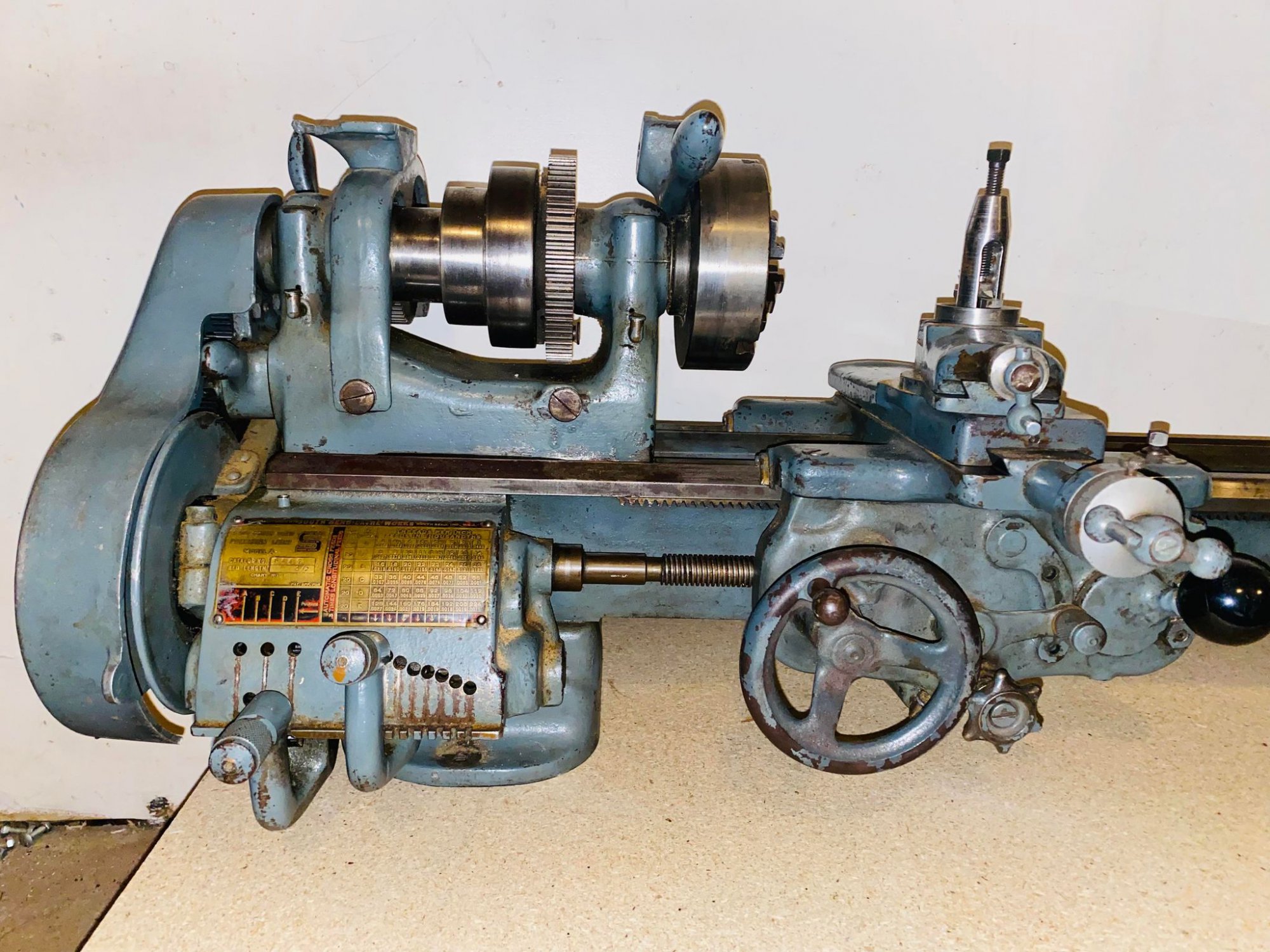

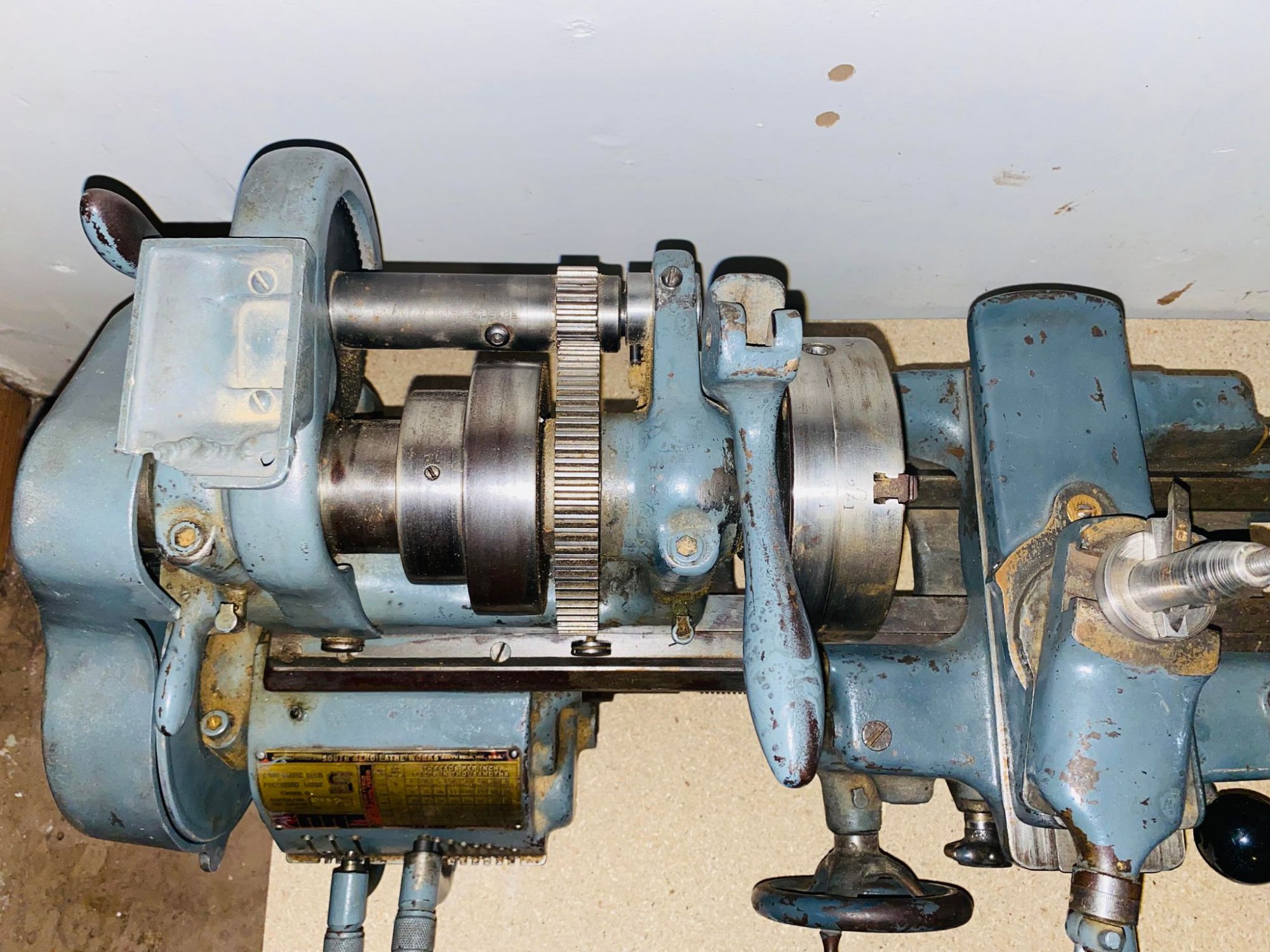

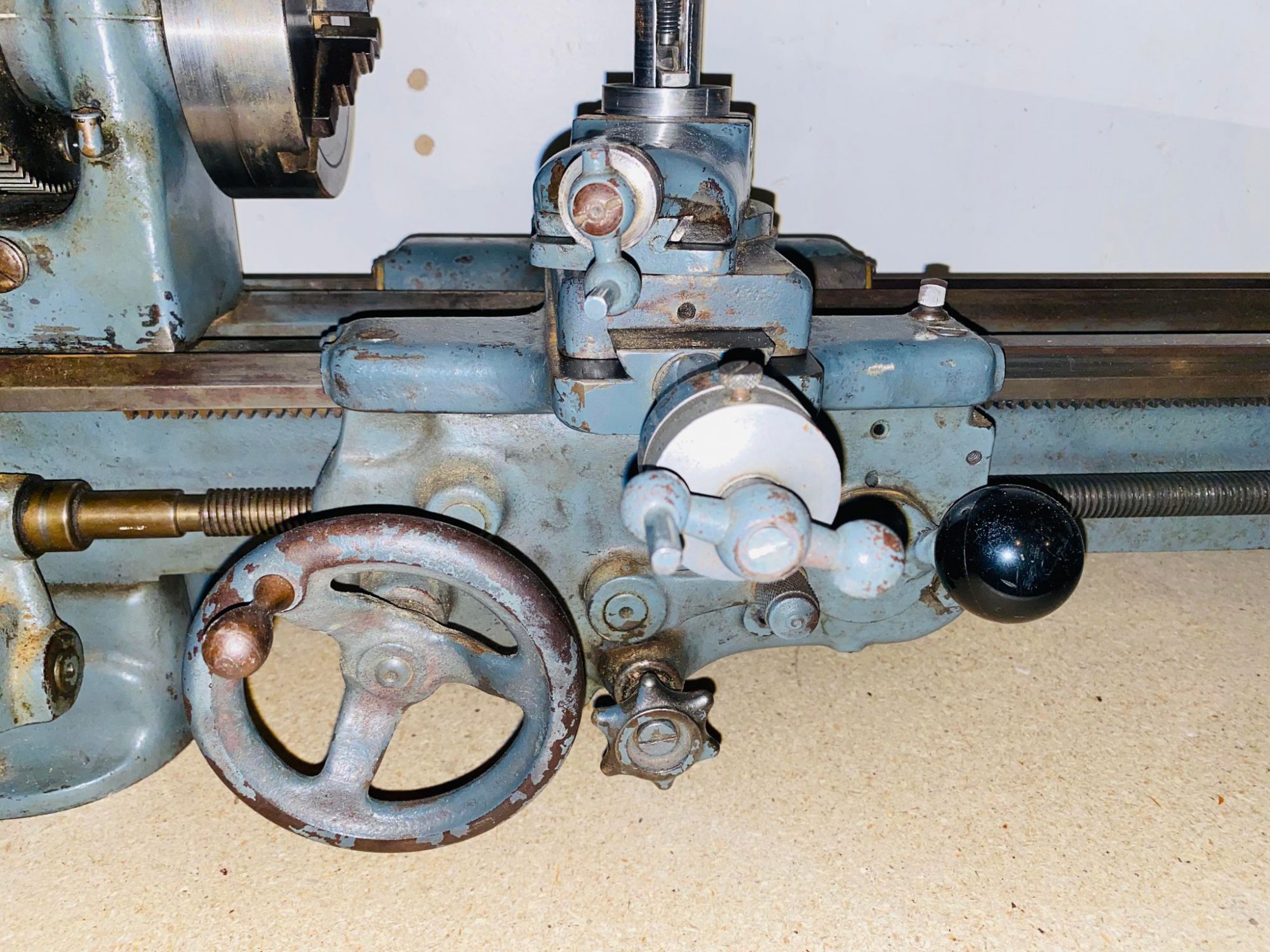

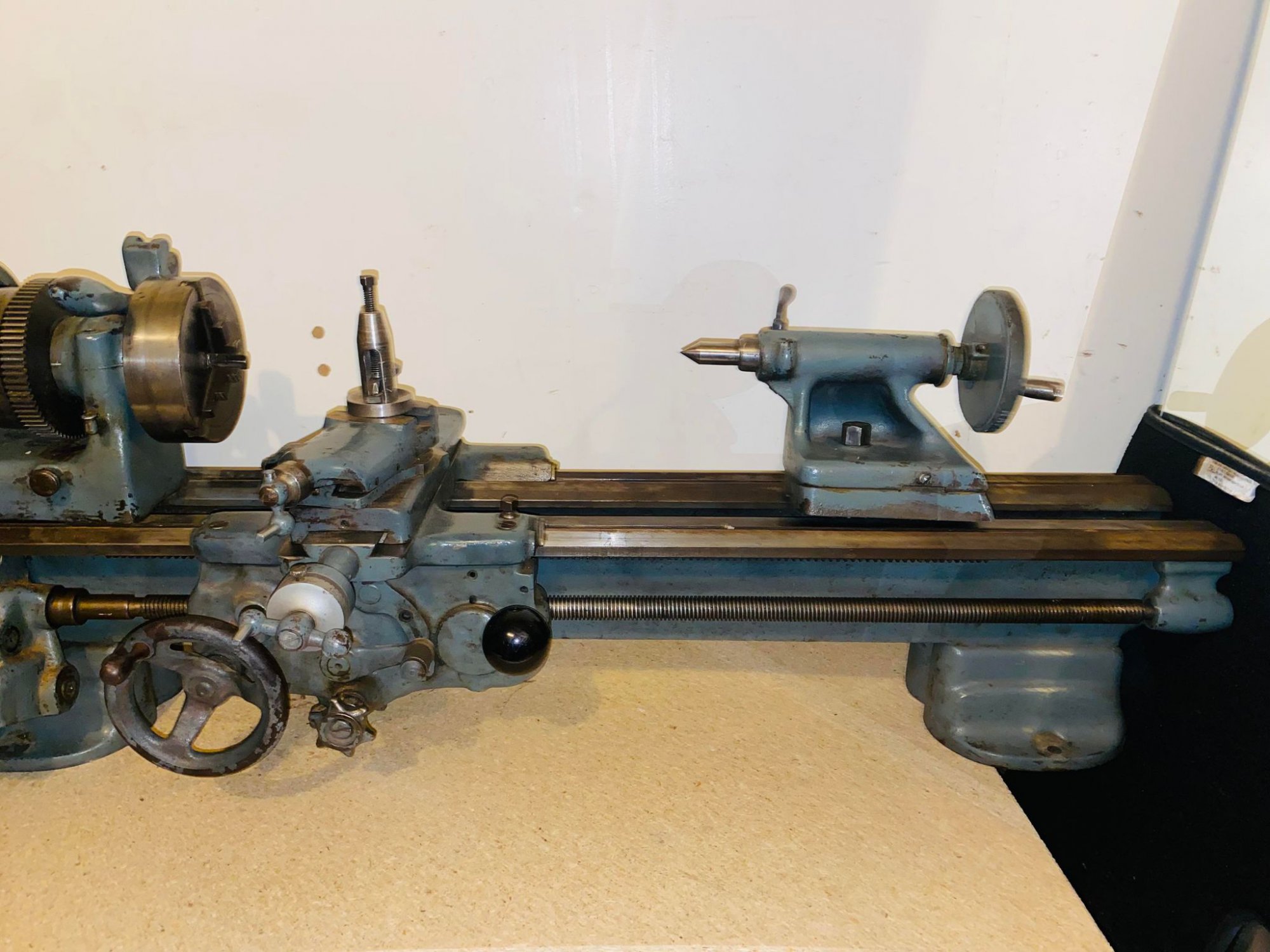

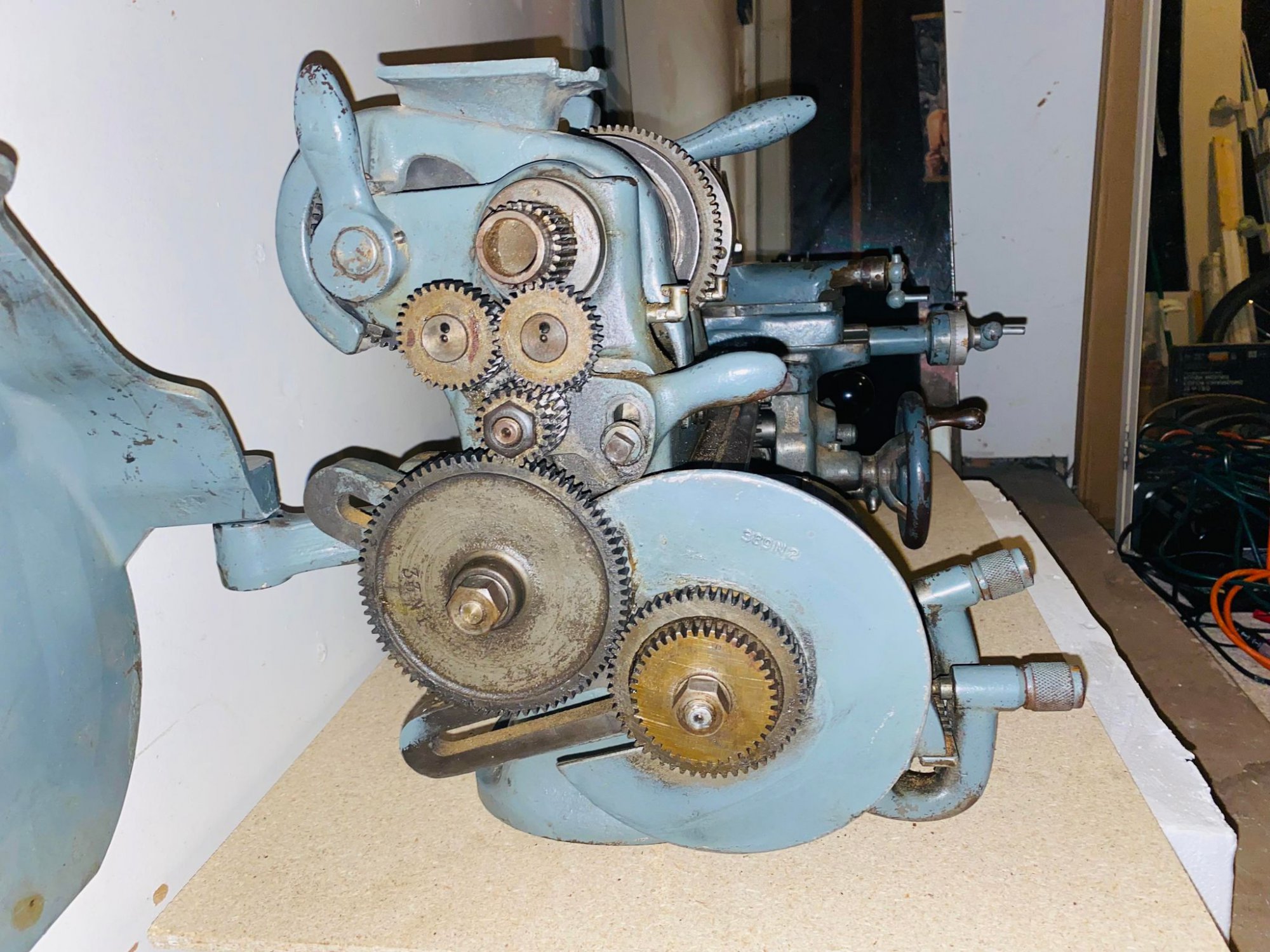

1) $550 - South Bend - Model A - 9" swing x 32" bed length.

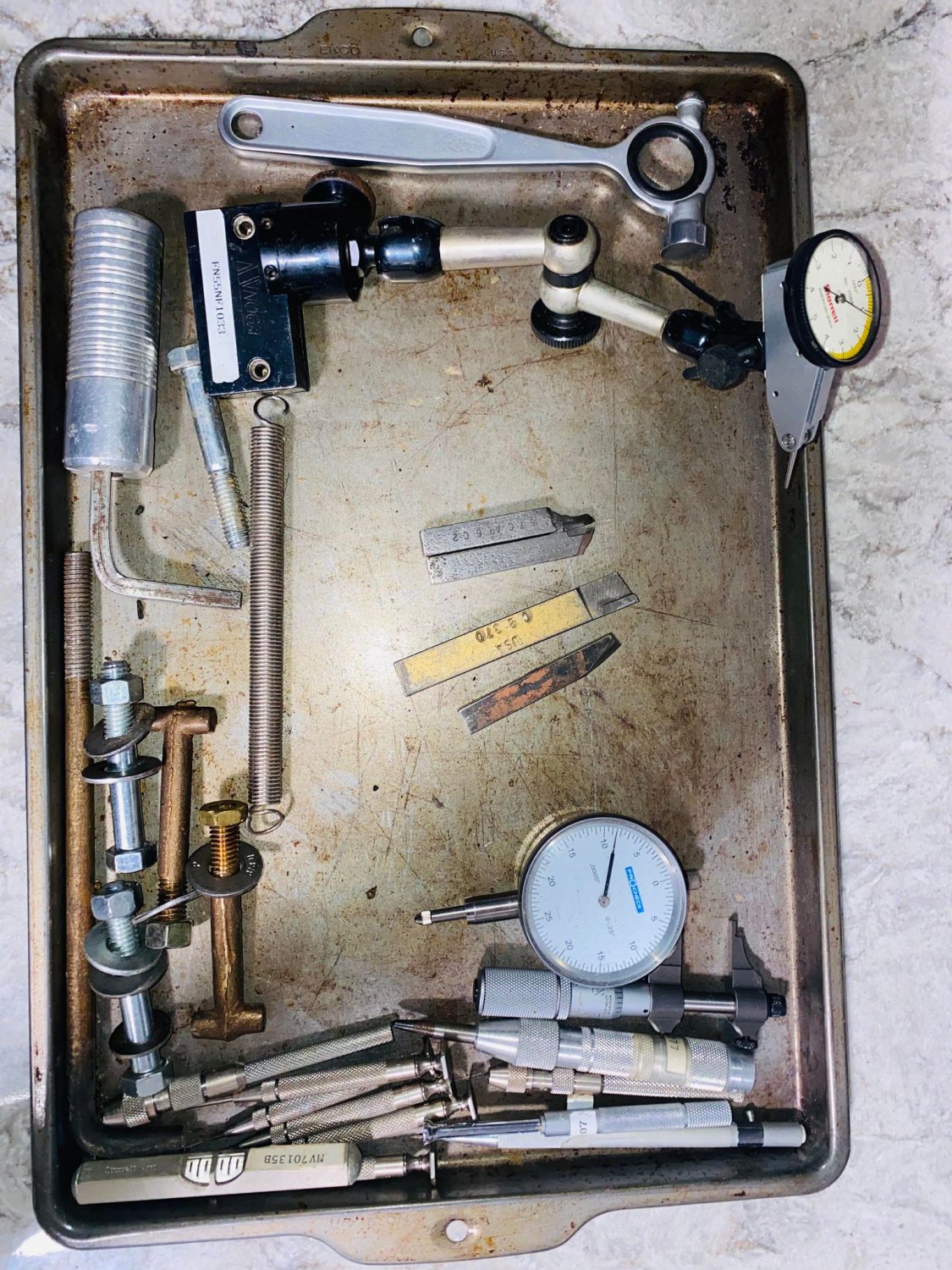

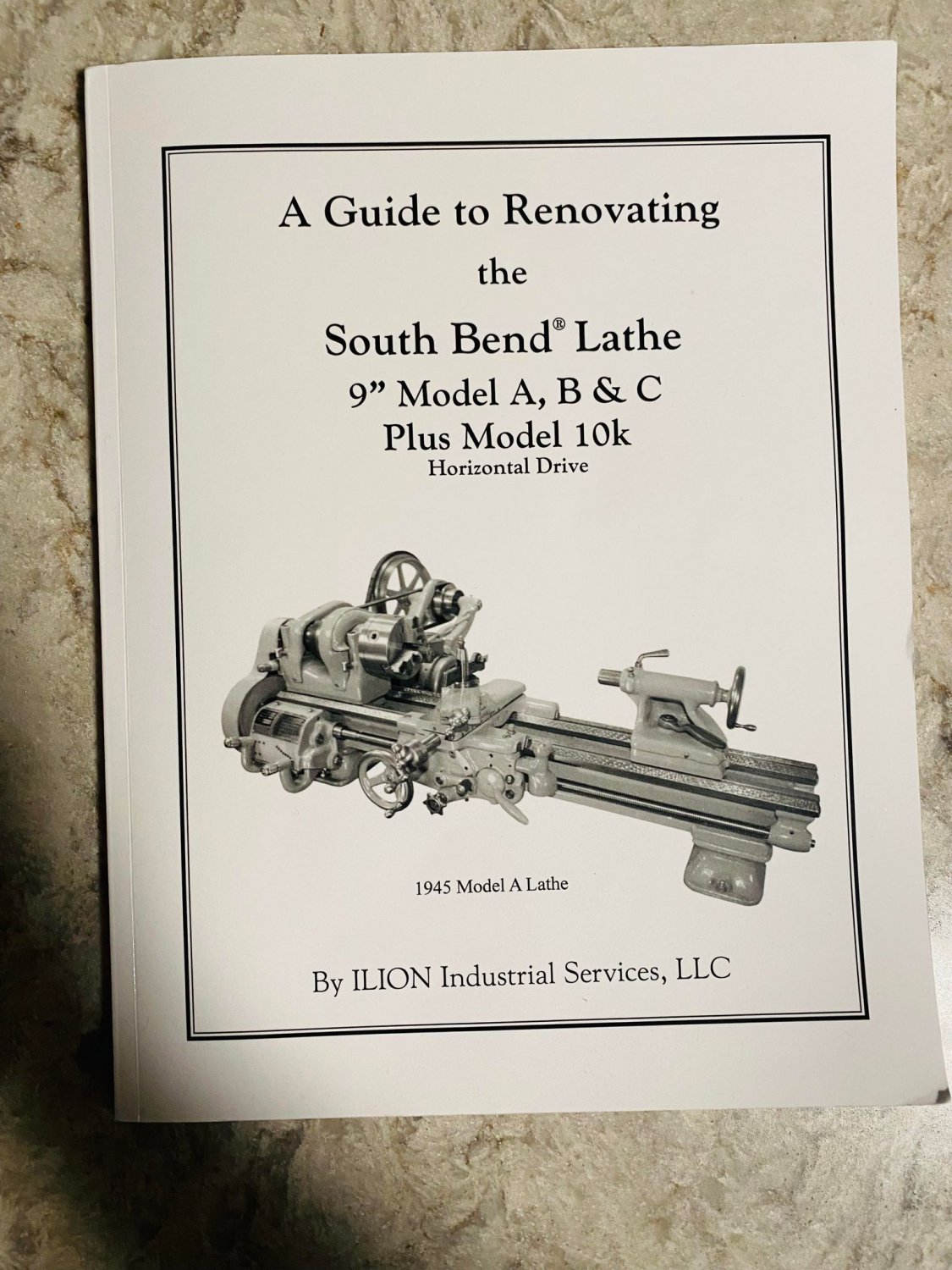

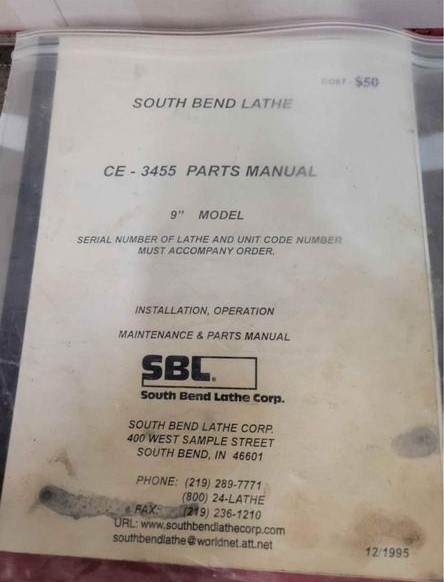

Needs a belt and comes with manual, book and tooling. 120 volt. Bench is not included.

Not operational without belt. Has the original belt but needs to be laced back together.

Pictures are below:

I will post more later on.

Thanks for advice.

I will start with the lowest price one first, which I think seems to be a good deal, wonder what everyone's thoughts are on it, if its a safe buy. I also don't mind rebuilding/scraping it so long not too expensive.

1) $550 - South Bend - Model A - 9" swing x 32" bed length.

Needs a belt and comes with manual, book and tooling. 120 volt. Bench is not included.

Not operational without belt. Has the original belt but needs to be laced back together.

Pictures are below:

I will post more later on.

Thanks for advice.