- Joined

- Apr 30, 2015

- Messages

- 11,327

You want the narrowest possible blade on a small light lathe such as that

not height 1/2 in width

no, more like 1/16 ............the wide flat part that goes in the T.H. is 1/2 in. X 4 in. longWait….when you look down at the parting blade in the tool holder are you saying it’s 1/2” wide???

1/2in. wide 4 in. long 1/16 thickI think we found your issue!

My 13x40 has a 3hp motor, and I don't think I could part with a 1/2" wide cutoff blade.

I'm kidding, and I'm assuming you're in error here. Or, are talking about a different dimension than the rest of us.

So, how 'thick' is the parting blade?

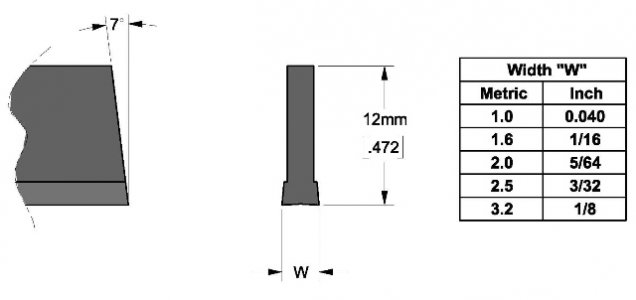

Dimension W, here:

View attachment 446931

For some reason, the pic is upside down.

its a V shape big part on topYou want the narrowest possible blade on a small light lathe such as that

the measurments you said above are correct.You can't possibly part with a 1/2" wide parting tool on a mini lathe. Typical parting tools for a mini lathe are 4-5" long x 1/2" high x 1/16" wide. No mini lathe has the power to handle a 1/2" wide parting cutter. Using an 1/8" wide blade is tough on a mini, I know, I've tried it.

4" long x 1/2" thick x 1/16" wide . Lets get you straight on how to measure things . You should be able to part with an .062 blade , if not , go smaller . Parting takes a good rigid set up also or bad things happen .1/2in. wide 4 in. long 1/16 thick

OTOH, it's unlikely his machine has sufficient power to break an inserted tool.Parting will always be difficult with a flimsy underpowered lathe, and insert parting tools will only cost money and break quite easily.